INDPRO ENGINEERING SYSTEMS P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to INDPRO ENGINEERING SYSTEMS P LTD.

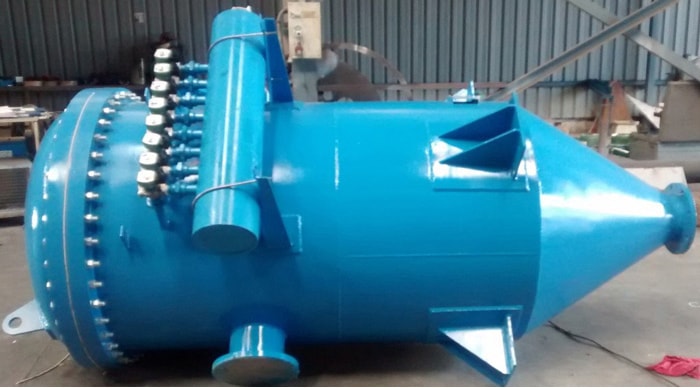

Cyclone And Scrubber System

Description / Specification of Cyclone And Scrubber System

We are involved in offering a wide range of Cyclone And Scrubber System to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Cyclone And Scrubber System. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Closed Loop Conveying System

Indpro Closed Loop Conveying (ICLC) System is the ideal method of pneumatically conveying hygroscopic, sterile, perishable and hazardous products such as Chemicals, sugar, starch, potato / milk powder and oxidising powders, Chemicals, where product exposure to unconditioned gas can cause product degradation and introduce material handling problems. Same system can cater to products that are sensitive to contamination, application such as baby food, pharmaceutical industry, highly explosive material etc.

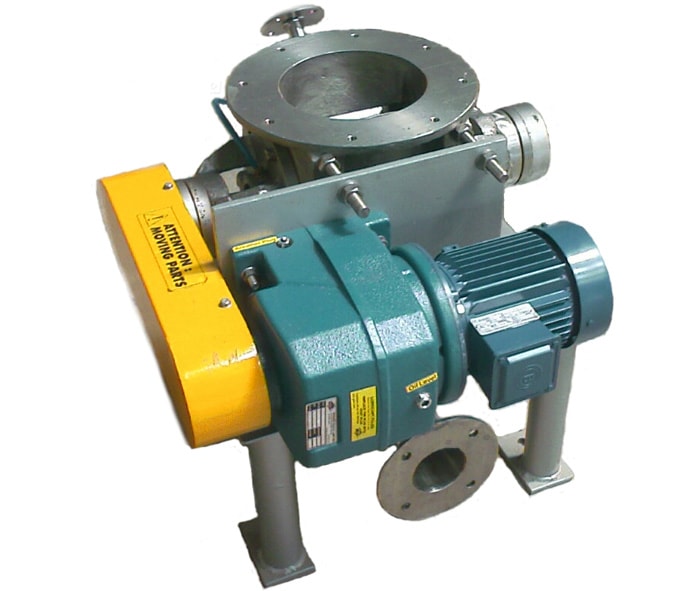

Powder Transfer System

Indpro makes PTS system is an efficient, reliable method of transferring and dispensing bulk powders, granules.

This system is a significant enhancement to any conventional, mechanical or pneumatic material conveying process and provides total dust free means of material transfer.

Screw Conveyor Tubular

Tubular Screw Conveyors and Feeders are manufactured from carbon steel with suitable surface finishing. They consist of a tubular trough equipped with at least one inlet and outlet spout, a welded flange at each tube end, helicoid screw flighting welded on a Centre pipe with a coupling bush at each end, two end bearing assemblies complete with self-adjusting shaft seal, a number of intermediate hanger bearings depending on the overall length of the screw conveyor.

Conventional Hose Filters

Commonly known as bag houses, dust collectors, pulse jet bag filters. Indpro’s fabric dust collectors use filtration to separate dust particulates from dusty gases. They have a feature of continuous operation with a built-in facility for automatic regeneration of filter elements. Today they are the most efficient and cost effective solution, capable of achieving emission levels as low as 5 mg/Nm3.

Automatic Bag Emptying Machine

THE BAG-EMPTYING MACHINE is designed for emptying paper, paper and polythene and polythene and raffia bags containing products in powder or granules. Depending on the customer's requirements, the bags can be sent to the emptying machine by means of a conveyor belt, a vertical elevator or an automatic depalletiser.

Blender

INDPRO Ribbon Blender comprises of a U-shaped horizontal trough and a specially designed Double Helical Ribbon Agitator rotating within. Ribbon Blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending. The dimensions and configuration of the ribbons are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge.

Engineered Solution

Description / Specification of Engineered Solution

We are involved in offering a wide range of Engineered Solution to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Engineered Solution. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Fabric Silos

Description / Specification of Fabric Silos

We are involved in offering a wide range of Fabric Silos to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Fabric Silos. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

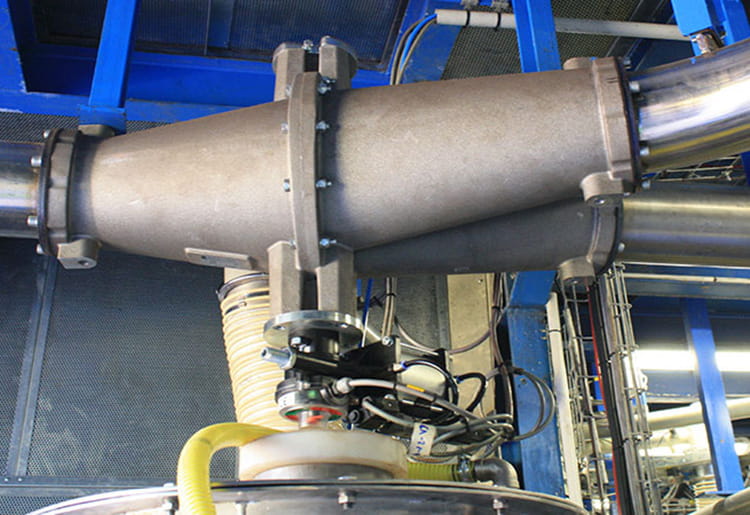

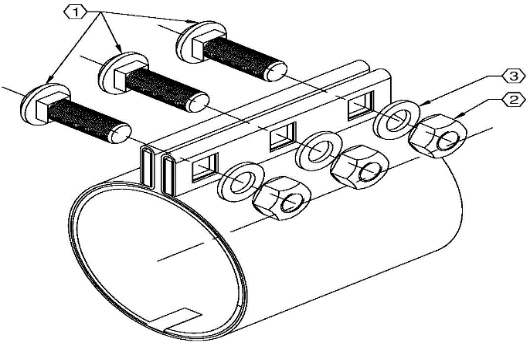

Pipe Coupling

Description / Specification of Pipe Coupling

We are involved in offering a wide range of Pipe Coupling to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Pipe Coupling. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.