ILPEA PARAMOUNT P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ILPEA PARAMOUNT P.LTD.

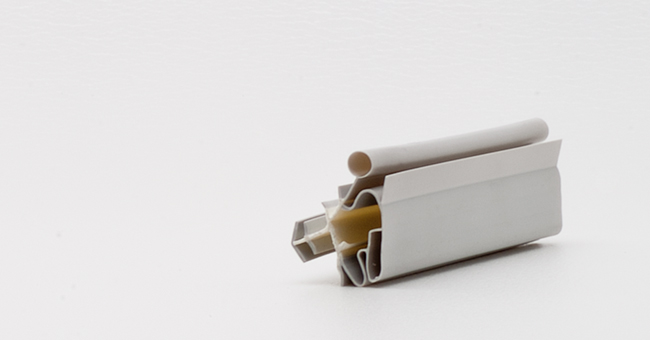

Extruded Gaskets And Profiles

Ilpea uses customer co-design techniques and builds custom-made tooling for the extrusion of rubber seals which have a wide variety of applications. Ilpea has extrusion facilities in Europe, the US, Mexico and India.

GASKETS AND PROFILES FOR THE HOUSHOLD APPLIANCES SECTOR These gaskets are made from extrusion and can be used plain for the sealing of the doors of dish washers and dryers. When used for sealing the revolving surfaces of washing machines and dryers, after the extrusion operation they are usually spliced, painted or coated with felt.

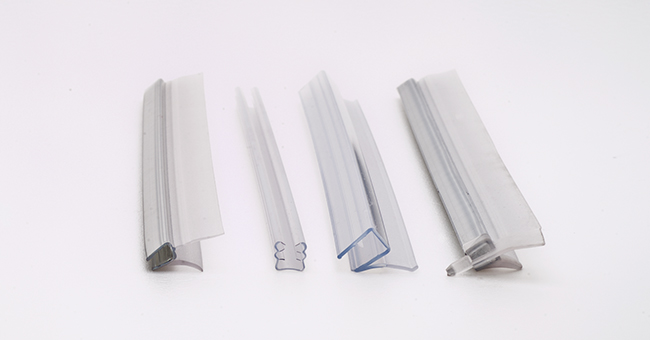

Gaskets And Profiles For The Building Sector

These are Ilpea’s drawing, large-size profiles (up to 40 kg/mt), which are designed for use in the road, tramway and port building sectors, or profiles for ashlars and tunnels that are made to customer’s specifications. They are characterized as being highly weather and chemical agent resistant.

Moulded Gaskets And Sleeves

MOULDED GASKETS AND SLEEVES These parts are made from injection moulding, primarily using vertical injection moulding machines. Ilpea develops these parts also using customer co-design techniques and makes the tooling that is necessary for their realization. Ilpea’s production sites for these parts are located in Italy, Poland, Mexico and India.

GASKETS AND SLEEVES FOR THE HOUSHOLD APPLIANCES SECTOR These gaskets ensure the sealing of front and top load washing machine doors. The sleeves are used for the connections between different parts of the machine. Both parts are generally made using mutly-cavity moulds. Ilpea supplies all the leading household appliances manufacturers and can develop any items requested by the customer in a very short time.

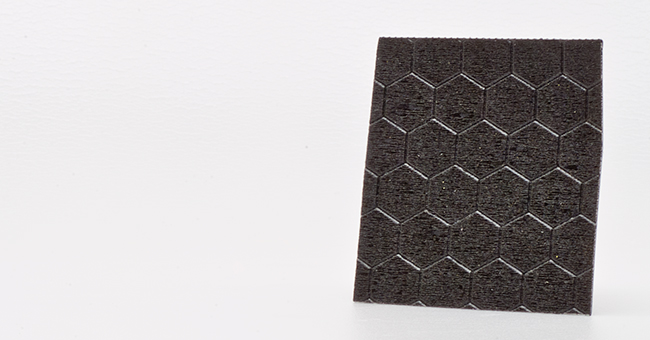

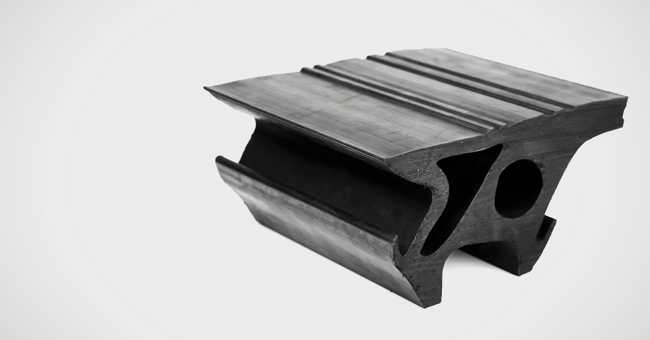

Compression Moulded Products For Road Construction And Building Industries

Ilpea manufactures these items in its production sites located in Italy and India. These parts may be made entirely of rubber. Ilpea has gained a wide experience in the production of compression moulded technical items that have the elasticity of rubber and the toughness of steel.

COMPRESSION MOULDED PRODUCTS FOR THE ROAD AND RAILWAY CONSTRUCTION INDUSTRIES.

These products may be entirely made of rubber. They include:

- neoprene mattresses, used to insulate railways from the ground

- trapeze-shaped fenders

- Venice’s Mose system fenders / bulkheads

- various types of rubber and steel sheets / plates made according to customers’ drawing

- bearings, in accordance with the following standards:

- EN 1337/3 for bearings made of neoprene or natural rubber (dielectric and non-dielectric rubber);

- BS 5400 for natural rubber or neoprene bearings;

- UNI CNR 10018 SBR;

- DIN 4141 for neoprene bearings

- road expansion joints, according to the UNI CNR 10018 standard (in dielectric and non-dielectric rubber)

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.