ILPEA PARAMOUNT P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ILPEA PARAMOUNT P.LTD.

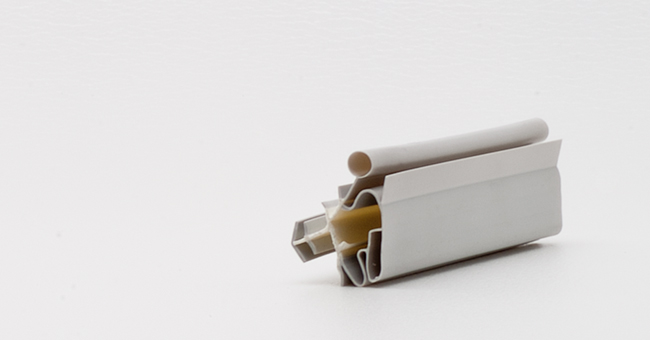

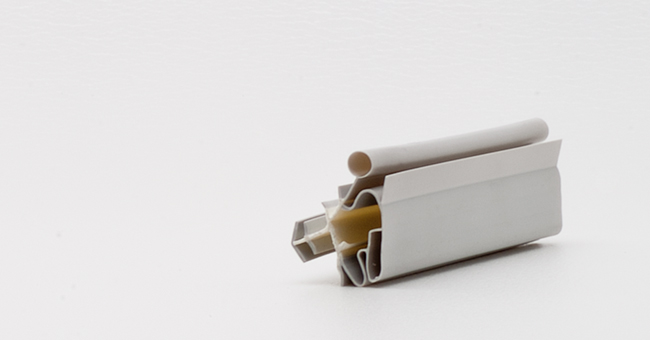

Gaskets For The Refrigeration Industry

"Push-in" type, tri-extruded magnetized TRIO gasket. This gasket profile is made from coextruded rigid and soft PVC and PU compounds, which besides providing excellent sealing properties also enhance energy-saving characteristics on refrigerator and freezer doors. Solutions for the automatic assembly of refrigerator and freezer doors. The Trio profile is protected by an international patent. For use on refrigerator doors, upright and combined freezers.

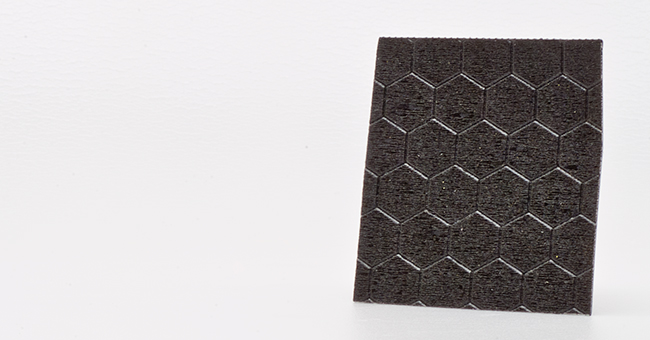

Pellets And Powders For Plasticizing

ILPEA has various production lines for making PVC and POLYOLEFIN compound powders and granules. Our R&D and Production can promptly meet any technical requirements, such as hardness, stability or level of migration of the compound, as well as any aesthetic needs, such as colour, roughness and opacity, and can manufacture industrial quantities in few hours. ILPEA’s plastic products are manufactured from in-house made powders and granules and TPE raw materials purchased from the sector’s worldwide leading companies.

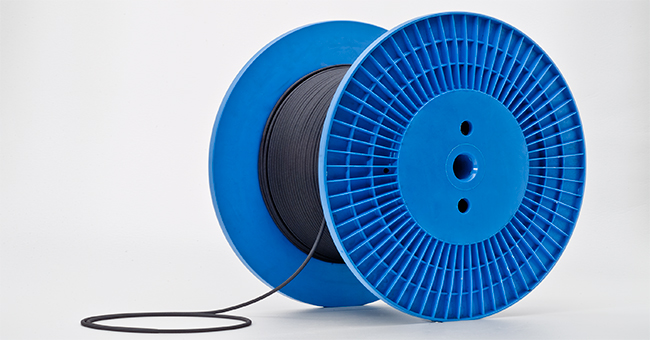

Polypropylene And Tpe Corrugated Hoses

This technology is primarily used for making internal and external tubes for washing machines and dishwashers, as well as for other applications. ILPEA has developed a totally automated technology – requiring no human intervention starting from the extrusion phase – to sevice the World’s leading household appliances manufacturers. The tubes are fitted with moulded tips and are certified through specific leakage tests. ILPEA hasin its range corrugated tubes for applications in the automotive industry (elastic suspension sleeves) and in the building sector (cable tubing and others). The company-owned OEM Miller brand is particularly well-known in these sectors in the USA and Mexico, where it caters for most of the local market needs.

Extruded And Co Moulded Shaped Tubes

The profiles for the automotive industry serve a double purpose: besides a more practical function,

such as providing sealing, shock absorption, bodywork protection and so forth,

they also play a major aesthetic role in that they enhance the car’s design.

Accuracy of execution and a superior aesthetic are therefore paramount.

ILPEA has gained a high level of expertise in the realization of car profiles,

and pays the utmost attention to performance and aesthetic requirements right from the first stages of product development,

by identifying and submitting to the customer the materials and technologies that are most suited to meet their needs.

ILPEA’s production includes finished extruded profiles, either comolded or overmolded, painted or plain,

made from materials such as polypropylene, TPE, santoprene, SEBS, soft or hard PVC and others,

all of which may be blended with various kinds of fibres or combined with aluminium or steel supports,

depending on the technical or aesthetic characteristics to be achieved.

Thanks to multi-extrusion processes employing different materials and to state-of-the-art profile bending techniques,

such as stretch bending or rollforming, Ilpea can satisfy any requests of its customers.

These profiles are used by the automotive industry on windscreens, car doors (window sealing strips, door side protections,

body side moldings, kick plates and others) and car roofs.

Worldwide famous car makers, such as AUDI, VOLKSWAGEN, SEAT, GM, OPEL, CHRYSLER and FORD,

have been using ILPEA’s high quality profiles since many years.

Slush Skins For Dashboards

CARING FOR DETAILS

The skin coating a car’s interiors, such as the dashboard, console cover and inside door panels, is an important factor affecting first impact when getting into a car. As a matter of fact , car trim skins can immediately convey a pleasant feeling of comfort, luxury and confidence or, reversely, can create an impression of toughness and sobriety as is the case of sportscars. Whatever the case, skins coatings are the result of very precise choices of materials, technologies and processes aimed at obtaining the desired effect.

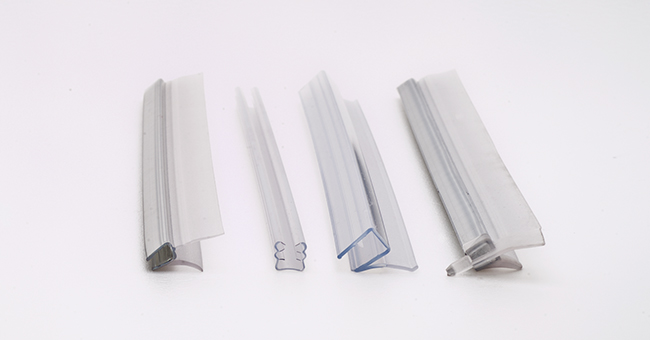

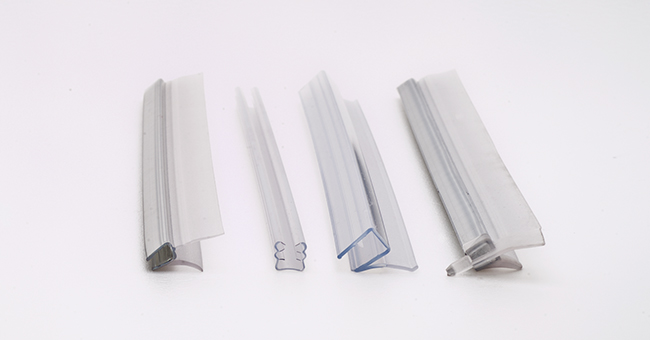

Extruded Profiles For Building Products

Extruded and coextruded profiles perform a double function: an aesthetic one and a practical one. The ideal profile must meet both these needs, thereby satisfying technical and functional requirements while, at the same time, offering a pleasant design. ILPEA has successfully addressed both aspects. The study of new materials and the fine-tuning of manufacturing systems designed to meet specific requirements have led to exciting results, allowing for profiles to be developed to cater for our customers’ every needs in a wide range of applications.

PROFILES FOR SHOWER STALLS ILPEA supplies standard and customized extruded or co-extruded profiles consisting of up to four different types of plastic materials combined together in one signle piece, with or without a magnetic strip or aluminium reinforcement. The use of polyolefin-based elastomerized profiles with a magnetic strip reinforcement has greately enhanced the user-friendliness of shower stall closing systems. The magnetized profiles used for the closing of shower doors are available with an ILPEA patented treatment (Patent No. EP1214554), which makes their mounting easier and avoids polarity errors. At the cusctomer’s request, all profiles may be supplied with a comoulded piece at both ends, which has both an estetic and a sealing function. The use of special materials and additives has allowed for the manufacturing of profiles in different colours which may be transparent, coloured to customers’ specifications or may have a metallic finish. ILPEA supplies the world’s most famous shower stall makers, such as DUSCHOLUX, HUEPPE, NOVELLINI, DUKA, KERMI, KORALLE and DUSAR.

Extruded Gaskets And Profiles

Ilpea uses customer co-design techniques and builds custom-made tooling for the extrusion of rubber seals which have a wide variety of applications. Ilpea has extrusion facilities in Europe, the US, Mexico and India.

GASKETS AND PROFILES FOR THE HOUSHOLD APPLIANCES SECTOR These gaskets are made from extrusion and can be used plain for the sealing of the doors of dish washers and dryers. When used for sealing the revolving surfaces of washing machines and dryers, after the extrusion operation they are usually spliced, painted or coated with felt.

Gaskets And Profiles For The Building Sector

These are Ilpea’s drawing, large-size profiles (up to 40 kg/mt), which are designed for use in the road, tramway and port building sectors, or profiles for ashlars and tunnels that are made to customer’s specifications. They are characterized as being highly weather and chemical agent resistant.

Moulded Gaskets And Sleeves

MOULDED GASKETS AND SLEEVES These parts are made from injection moulding, primarily using vertical injection moulding machines. Ilpea develops these parts also using customer co-design techniques and makes the tooling that is necessary for their realization. Ilpea’s production sites for these parts are located in Italy, Poland, Mexico and India.

GASKETS AND SLEEVES FOR THE HOUSHOLD APPLIANCES SECTOR These gaskets ensure the sealing of front and top load washing machine doors. The sleeves are used for the connections between different parts of the machine. Both parts are generally made using mutly-cavity moulds. Ilpea supplies all the leading household appliances manufacturers and can develop any items requested by the customer in a very short time.

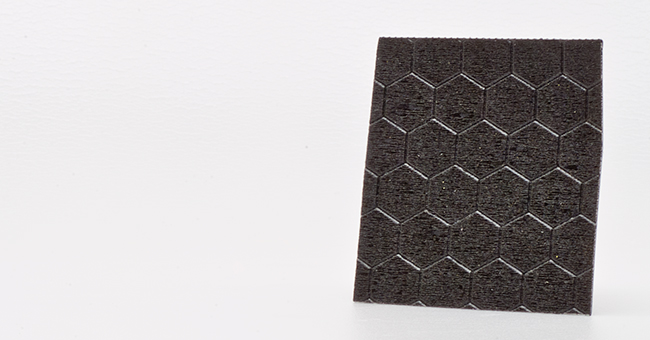

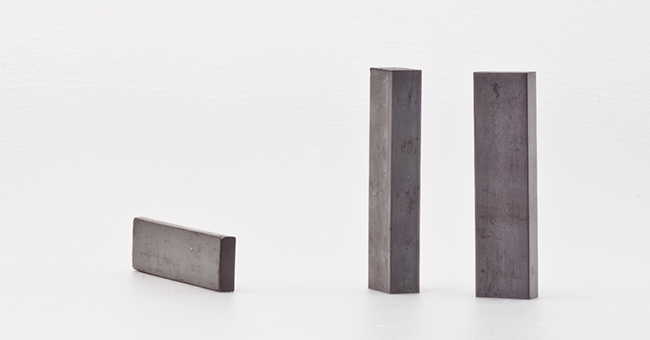

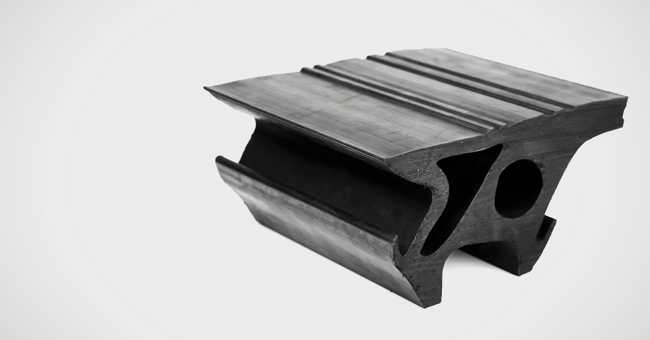

Compression Moulded Products For Road Construction And Building Industries

Ilpea manufactures these items in its production sites located in Italy and India. These parts may be made entirely of rubber. Ilpea has gained a wide experience in the production of compression moulded technical items that have the elasticity of rubber and the toughness of steel.

COMPRESSION MOULDED PRODUCTS FOR THE ROAD AND RAILWAY CONSTRUCTION INDUSTRIES.

These products may be entirely made of rubber. They include:

- neoprene mattresses, used to insulate railways from the ground

- trapeze-shaped fenders

- Venice’s Mose system fenders / bulkheads

- various types of rubber and steel sheets / plates made according to customers’ drawing

- bearings, in accordance with the following standards:

- EN 1337/3 for bearings made of neoprene or natural rubber (dielectric and non-dielectric rubber);

- BS 5400 for natural rubber or neoprene bearings;

- UNI CNR 10018 SBR;

- DIN 4141 for neoprene bearings

- road expansion joints, according to the UNI CNR 10018 standard (in dielectric and non-dielectric rubber)

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.