ILPEA PARAMOUNT P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ILPEA PARAMOUNT P.LTD.

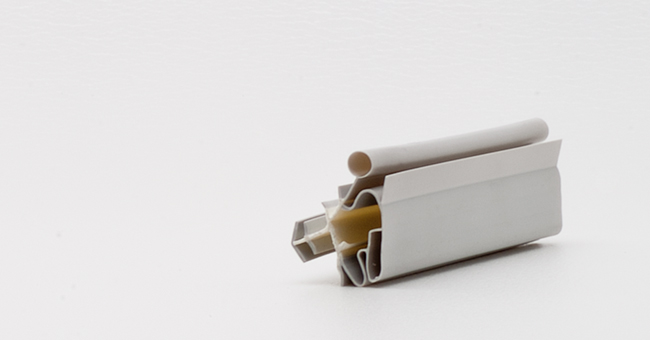

Polypropylene And Tpe Corrugated Hoses

This technology is primarily used for making internal and external tubes for washing machines and dishwashers, as well as for other applications. ILPEA has developed a totally automated technology – requiring no human intervention starting from the extrusion phase – to sevice the World’s leading household appliances manufacturers. The tubes are fitted with moulded tips and are certified through specific leakage tests. ILPEA hasin its range corrugated tubes for applications in the automotive industry (elastic suspension sleeves) and in the building sector (cable tubing and others). The company-owned OEM Miller brand is particularly well-known in these sectors in the USA and Mexico, where it caters for most of the local market needs.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.