ILPEA PARAMOUNT P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ILPEA PARAMOUNT P.LTD.

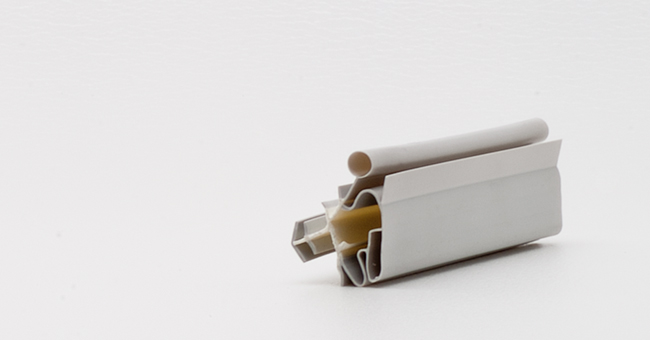

Extruded And Co Moulded Shaped Tubes

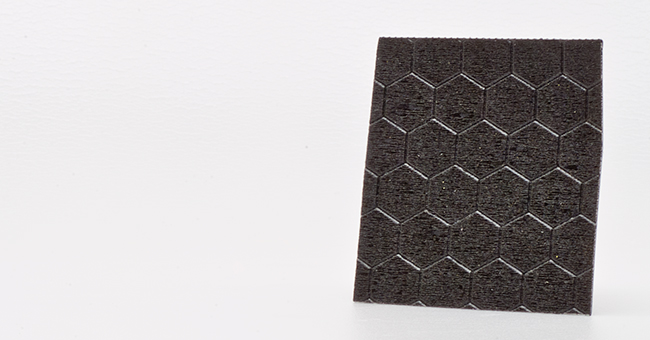

The profiles for the automotive industry serve a double purpose: besides a more practical function,

such as providing sealing, shock absorption, bodywork protection and so forth,

they also play a major aesthetic role in that they enhance the car’s design.

Accuracy of execution and a superior aesthetic are therefore paramount.

ILPEA has gained a high level of expertise in the realization of car profiles,

and pays the utmost attention to performance and aesthetic requirements right from the first stages of product development,

by identifying and submitting to the customer the materials and technologies that are most suited to meet their needs.

ILPEA’s production includes finished extruded profiles, either comolded or overmolded, painted or plain,

made from materials such as polypropylene, TPE, santoprene, SEBS, soft or hard PVC and others,

all of which may be blended with various kinds of fibres or combined with aluminium or steel supports,

depending on the technical or aesthetic characteristics to be achieved.

Thanks to multi-extrusion processes employing different materials and to state-of-the-art profile bending techniques,

such as stretch bending or rollforming, Ilpea can satisfy any requests of its customers.

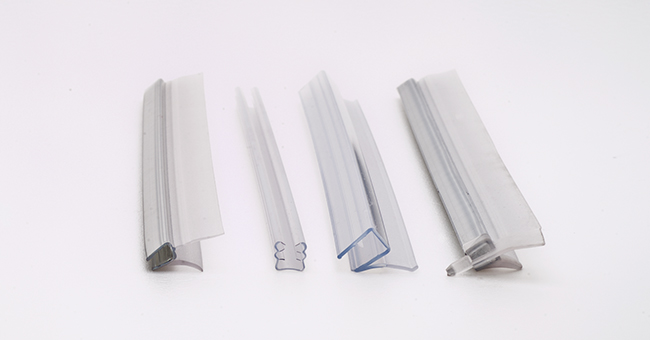

These profiles are used by the automotive industry on windscreens, car doors (window sealing strips, door side protections,

body side moldings, kick plates and others) and car roofs.

Worldwide famous car makers, such as AUDI, VOLKSWAGEN, SEAT, GM, OPEL, CHRYSLER and FORD,

have been using ILPEA’s high quality profiles since many years.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.