IEC FABCHEM LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to IEC FABCHEM LTD.

Cabinet Mounted Chlorinators

Model R-103 floor cabinet mounted chlorinators are vacuum operated, solution feed devices available with wall mounted remote vacuum regulator. The injector is floor mounted, away from the Chlorinator cabinet, which houses a Rotameter, a flow control valve, a differential regulator and a vacuum relief valve.

REMOTE VACUUM REGULATOR

Exclusively designed remote vacuum regulator is a vacuum-to-open and normally closed. It continuously monitors vacuum and regulates gas flow to a closely controlled value. When located as close as possible to the source of gas supply, the risk of handling gas under pressure is reduced to a minimum.

INJECTOR

Capacities up to 40 Kg/hr of chlorine have a fixed throat. Capacities of 50 kg/hr chlorine and above are equipped with variable orifices, which may be achieved by a throttle valve on injector, so that water consumption may if necessary reduced to a minimum. Water passing through injector should reasonably clean.

INJECTORS ARE SELECTED TO CREATE VACUUM AND TO LIMIT CHLORINE SOLUTION STRENGTH TO 3500 ppm AT 25 C OR 2500 ppm AT 40 C AT HIGHER CONCENTRATIONS MOLECULAR CHLOLRINE BREAKS AND FUMES AT THE POINT OF APPLICATION, CAUSING INEFFICIENT MIXING OF CHLORINE

Frame Mounted Chlorinators

Model WM Frame mounted Chlorinators are solution feed, vacuum operated, frame mounted type. Feed range is 20 to 1 for the rotameter. The flow meter maintains the set feed rate within 4% of indicated flow.

Operating components are mounted on moulded fibre glass panel. The panel and other accessories like injector are totally mounted on a frame, suitable for floor mounting.Vacuum regulator is of exclusive design for a vacuum to open type safety feature. It opens only under normal operating vacuum.

Steriflo Water Supply Disinfection System

IEC’s STERIFLO Water Disinfection System provides safe treated water. The technology is user friendly and safe to operate. An ideal situation would be to treat water on the spot of pumping at the overhead tank supply pipeline. IEC provides a reliable Chloridose Generator to produce Sodium ypochlorite on site using common salt, AC power supply and water. A dosing pump is used to dose the Chloridose solution for treating drinking water.

STERIFLO system introduces a pre-measured quantity of Chloridose solution into the water supply.

OPERATION: Chloridose generates Sodium hypochlorite solution. The solution is transferred to the dosing tank. From the dosing tank, Chloridose is dosed by dosing pump.

AUTOMATIC DOSING: The Dosing pump is automatic. As soon as the water flows in the distribution main , Chloridose injects solution at preset value. Steriflo disinfection units for drinking water supply schemes is available in eight standard models. Chlorination is considered at 1 to 2 ppm dosage at the point of injection.

Hydro Pure Drinking Water Purification System

HYDROPURE system provides filtered pure disinfected drinking water. The process of filtration and disinfection is fully automatic . Simply connect the supply line to HYDROPURE skid to get treated water by opening the tap. The turbidity of water input to HYDRO PURE system should be not more than 50 NTU. Steriflo generates sodium hypochlorite (using only common edible salt) to disinfect water suitable for drinking.

Steam Heated Vapourizer

The design & manufacture of Steam Heated Vaporizer meets Chlorine Institute recommendations for liquid vapourization by low pressure steam. The liquid is inside the tube and the heating media is steam vapour which is outside the tube.

The vapourizer design pressure of 300 lbs meets Chlorine Institute Recommendations with corrosion allowance of 3 mm on chlorine side and 1.5 mm on steam side.

Series SC 70 Vapourizer is of heavy duty construction. The internal and external surface of the vapourizing chamber can be easily inspected during servicing which is an unique feature of the design. Ease of cleaning is an added advantage to remove the sediments.

SC 70 can be easily cleaned by removing the top bolt. Suction trap has a sacrificial chamber provided at the gas outlet which protects the main body from corrosion attack.

The Steam chamber has nozzle connections for steam inlet, condensate outlet, pressure gauge, pressure switch and pressure relief valve. Insulation on shell must be done by the client at site.

OPERATING PRINCIPLE

In operation, liquid is introduced through liquid inlet which is connected to the bottom of the vapourizer tube by a dip pipe. Here the liquid rises to contact sufficient surface to meet the vapour demand rate. After equilibrium is reached vapourizer operates at essentially on container pressure.

As gas demand reduces, vapourizer the pressure at the vapourizer raises thus reducing the inflow of liquid feed. On sudden shut down of gas valve, liquid would be forced out of vapourizing chamber back to the container.

With evaporation, the vapour raises through the vapour baffle to the super heating chamber, enters the suction trap and leaves through the gas outlet. Suction trap collects moisture and prevents such moisture from corroding vapourizer chamber. Since suction trap is not a pressure part it can be severely corroded without impairing operation or safety.

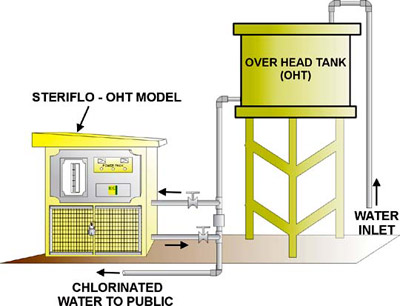

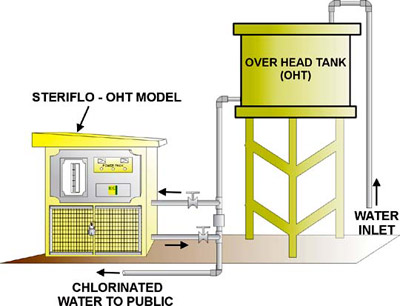

Steriflo Oht Installation

ADVANTAGES OF STERIFLO-OHT

- Only common salt and AC power is required.

- Online chlorine generation and dosing.

- Not dependent on chemicals.

- Helps in ensuring tail end ppm of minimum 0.5 as per WHO requirements, when water Distribution from the over Head tank is delivered to the consumer in a short span of time.

- Least attention is required by the operator.

- Simple and easy maintenance procedure.

- A permanent solution to eliminate possible water borne diseases.

- Eliminates problems associated with bleaching powder /Toxic Chlorine gas.

- Avoids hazards associated with chlorine

- Gas which requires Elaborate safety system.

- Assured system quality, performance with

- service back up for long Term operation.

- Very Cost Effective.

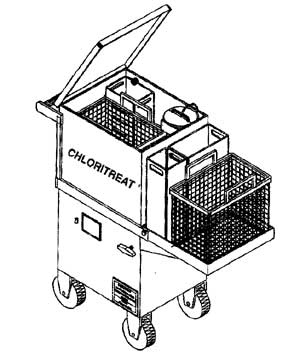

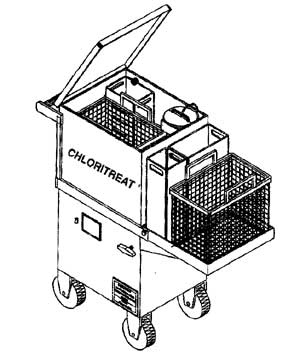

Medical Waste Sterilizer

Now Sterilize and dispose Medical waste by CHLORITREAT Sterilizer without hazardous chemicals or incineration.

CHLORITREAT Sterilizes medical waste in a safe and cost effective manner. It does not use any costly or hazardous chemicals. Only POWER, SALT and WATER are required for sterilizing the waste.CHLORITREAT APPLICATION IN MEDICAL WASTE DISPOSAL

As per the guidelines of THE BIO-MEDICAL WASTE MANAGEMENT AND HANDLING RULES 1998, the following categories of waste are to be treated by disinfection / deformation prior to disposal.

CHLORITREAT

Produces 1% Sodium Hypochlorite

Coolingwater Treatment By Uv Sterilizer

- UV light will kill any DNA based micro organism when give enough UV dosage.

- UV break micro organism’s DNA in a cumulative basis.

- Continuous disinfection in cooling water. If micro organism is not effectively deactivated on the first disinfection cycle and in the next cycle it get UV treated.

- For 90% kill algae 30000 µWs/cm2 is required for one cycle .

- UV spectrum between 185-400nm has a strong germicidal effect, with peak effectiveness at 265nm.

- UV works instantaneously against all water-borne microorganisms, including bacteria, viruses, molds, spores and protozoa – including those resistant to chlorine.

- UV systems are also very easy to use and can be effectively monitored and integrated with online process control systems.

- UV disinfection systems are very compact, modular and easy to

- install into existing water treatment systems.

- UV does not cause the formation of chemical disinfection by-

- products, many of which can have undesired effects of their own.

- UV sterilizer is eco-friendly and cost effective.

Automatic Valveless Gravity Filter

FEATURES AND ADVANTAGES

- HANDLES INLET SUSPENDED SOLIDS LOAD UP TO 25/50PPM WHILE GIVING CONSISTENT HIGH QUALITY TREATED WATER OF LESS THAN 10µM.

- COMPACT AND MODULAR DESIGN

- LOW INSTALLATION COST FOR ADD ON FILTERS

- NO VALVES, INSTRUMENTS ,BACKWASH PUMPS & BLOWER IS REQUIRED FOR OPERATION

- RINSE WATER THROUGH A FRESHLY BACKWASHED AUTOMATIC VALVELESS GRAVITY FILTER IS NOT DISCARDED. BUT STORED AND USED FOR NEXT BACKWASH CYCLE, IT SAVES WATER.

- NO POWER REQUIREMENT FOR OPERATION

- OPERATION IS SIMPLE THAT FILTERS CAN BE “FIT AND FORGOT”

- NO MANPOWER REQUIRED FOR OPERATING & MONITORING

- STORES OWN RESERVOIR OF BACKWASH WATER HENCE NO WATER STORAGE IS REQUIRED FOR BACK WASH.

- BACKWASH TIME 5-10MIN

- IT CAN BE PLACED IN OPEN AIR

- IDEAL FOR USE IN HAZARDOUS ZONE AREA

- NO AIR REQUIRED FOR SCOURING PURPOSES AND THEREFORE BLOWER IS NOT NEEDED.

- NO MOVING PARTS

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.