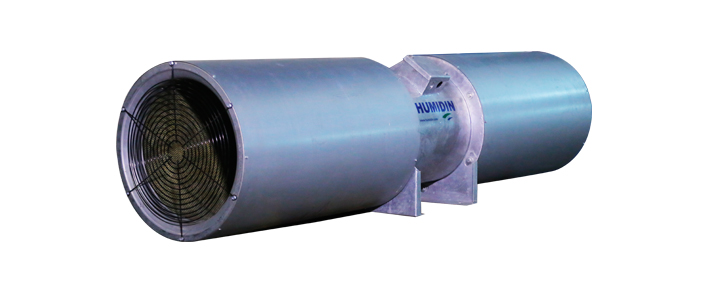

Centrifugal Blower Forward Didw

HUMIDIN's Centrifugal Forward Curved Fans/Blowers consist of Double Inlet Double Width(DIDW) and Single Inlet and Single Width (SISW) configuration. These fans have forward curved impellers with forward curved blades having special profile to give you maximum efficiency at low noise levels. These impellers are statically and dynamically balanced. The fans are suitable for various applications where high volume air displacement is required like air cooling, general ventilation, pressurization, etc., in various commercial processes and various industrial HVAC systems. HUMIDIN's ACFC Series of fans are certified for 'Sound & Air Performance' by AMCA.

DISCERNIBLE FEATURES:

Fan Size(Dia): 180 mm to 1120 mm

Flow rates up to 1700 to 190000 cmh

Pressures up to 100 Pa to 1200 Pa

APPLICATIONS For commercial and industrial ventilation in AHU´s, Evaporative Coolers, other HVAC systems, etc.

71932.jpg)

71934.jpg)