HRS PROCESS SYSTEMS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HRS PROCESS SYSTEMS P.LTD.

Ecoflux Corrugated Tube Heat Exchanger

Ecoflux* Corrugated Tube Heat Exchangers (CTHE) use corrugated tubes instead of smooth tubes. The corrugations induce turbulence in the media and ensure high Reynolds number even at low velocity. The development of corrugated tube is perhaps the most exciting advancement in heat transfer technology.

Ecoflux Smooth Tube Heat Exchangers

HRS Process Systems Limited also designs and manufactures ECOFLUX* Smooth Tube Heat Exchanger for various industrial application like heating, cooling, condensing and reboiling in our world class manufacturing facility to cater to Customer's heat transfer requirement. We manufacture units presently to working pressure of 80 bar for process / service plant and with 0 temperature upto 400 C. For specific design we can manufacture units with 150 bar pressure at 500 C.

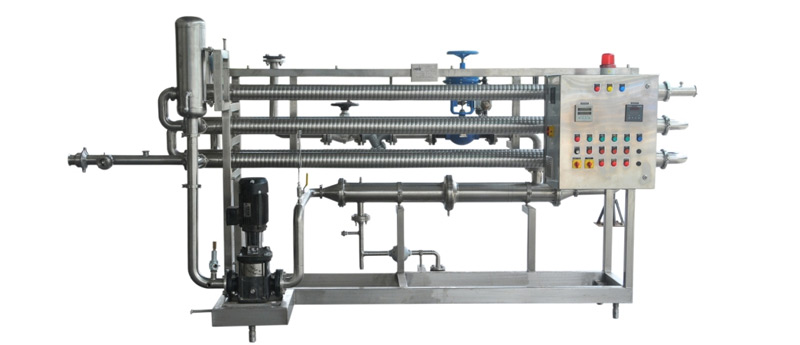

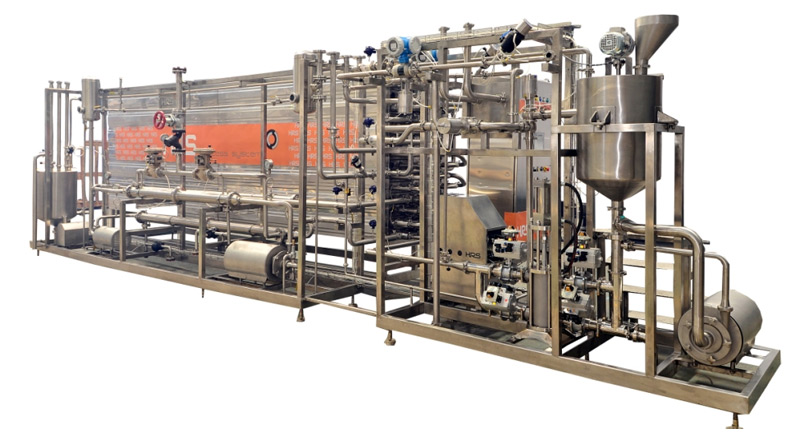

Heat Exchanger Based Systems

HRS Process Systems offers customised heat exchanger based systems (HES) as innovative heat transfer solutions for various key applications across process industry sectors. This is in line with the global reputation of HRS for providing sustainable, energy efficient range of heat exchangers and heat exchanger based systems (HES). HRS Heat exchanger based systems (HES) are usually skid mounted systems complementing the main plant. Through good process expertise, our systems ensure to recover energy which would otherwise have been lost to environment, thus making the overall plant much more environmentally efficient.

Unicus Scraped Surface Heat Exchanger

HRS has developed the Unicus® heat exchanger for difficult and critical processes where other types of heat exchangers such as rotary scraped surface heat exchanger, shell and tube or plain type are incapable of offering an adequate solution. Unicus® is capable of generating high levels of turbulence in products of high viscosity increasing substantially the overall heat transfer coefficient. In addition it does not allow the formation of any fouling layers on the inner tube surfaces and always stays clean enabling the unit to work in the optimum condition for efficient heat transfer at all times.

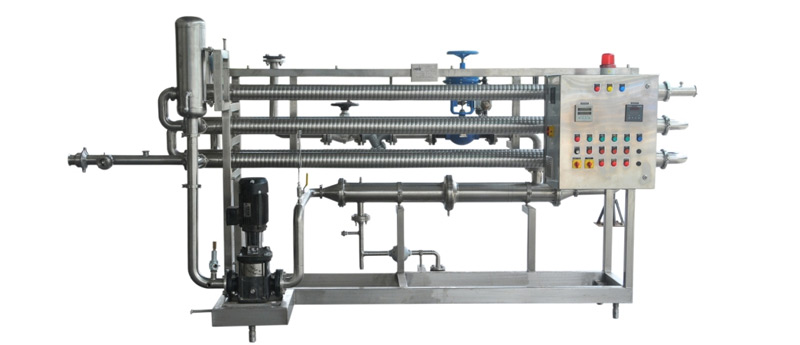

Pre Heaters And Pasteurisation Systems

HRS ECOFLUX* based pre-heaters, pasteurisers heat the product to desired temperature and holding it for appropriate time for inactivation of microbes. The preheating or pasteurization system can be integrated with evaporators, sterilizers and fillers as per customer requirement. Accurate automation through these systems minimizes intervention of operator thereby reducing errors.

Evaporation System For Fruits And Vegetables

In Food applications, concentrating fruit pulps for bulk transportation and reduction of water activity for longer shelf life necessitated the concept of evaporation. Evaporation is the process of vaporizing the water from a solution to produce concentrated product.

Integrated Automated Cip Station

CIP Stands for Clean-in-Place. The technology of CIP is vital in food industry as the process demands highly hygienic and aseptic environment. Food safety standards like HACCP and ISO demand effective CIP procedures, to eliminate microbial contamination of the foods being processed, which might consequently lead to food poisoning at the consumers' end.

Aseptic Fillers

In order to satisfy the demands of the modern food-processing sector HRS Process Systems has taken a decisive step in the integration of technologies. We have developed an integrated system which combines their innovative Hygienic Piston Pump, Unicus® dynamic heat exchangers, Ecoflux*corrugated tube heat exchangers depending on the process and their bag-in-drum Aseptic Fillers.

Aseptic Sterilizer

HRS PSL has developed aseptic steriliser with ECOFLUX* 'AS' series tube in tube heat exchangers to sterilise fruit puree, concentrate and tomato paste, multi tube heat exchanger to process heat sensitive fruit puree and juices and double tube heat exchanger to process fruit puree and juices with particulates.

Hygienic Piston Pumps

HRS Process Systems has found the solution to all of these with a piston pump which

Does not break the product.

Delivers high flow rates (up to 12 m3/hr).

Allows high-pressure losses (30 bar).

Can work under vacuum.

Is self-priming.

Can work empty (without product).

Requires few spare parts.

Has no rubber in contact with the product.

Can work at high temperatures (100°C)

Adjustable flow

Hrs Paradice

HRS ParaDice* is a unique offering for dices and ready to eat food processing industry which is capable of processing fruit dices / vegetable dices without shearing them. In this cutting edge solution, dices are pumped using HRS Hygienic Piston Pump and are heated and cooled in the highly efficient ECOFLUX* Double Tube Heat Exchangers. The fruit dices can be pasteurised or aseptically processed using the ParaDice*. HRS ParaDice* can be used for processing diced fruits, particulate foods, blanching of vegetables, pasteurisation and chilling of Ready-to-Eat foods, and similar applications.

Beverage Pasteurizer And Turnkey Beverage Processing Line

Description / Specification of Beverage Pasteurizer And Turnkey Beverage Processing Line

We are involved in offering a wide range of Beverage Pasteurizer And Turnkey Beverage Processing Line to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Beverage Pasteurizer And Turnkey Beverage Processing Line. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.