Products & Services

Blades For Packaging Industry

Description / Specification of Blades For Packaging Industry

We are involved in offering a wide range of Blades For Packaging Industry to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Blades For Packaging Industry. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Grinders

We offer a wide range of Grinders as below

1. State of art Size Reduction (Grinding) Machines us applicationz we have wide range of size reduction equipments commonly known as Grinders made specially for following applications.

A) For Lumps and articles in various size and capacities.

B) For hollow article grinder for drums and chairs etc

C) For PVC/HDPE pipes

D) Hopped Feed/Screw Force Feeder Grinder for PET Bottles which can be used for WET/DRY cutting

E) High performance Grinders / Cutters for Fibrous waste (Polyester / Nylon fibre)

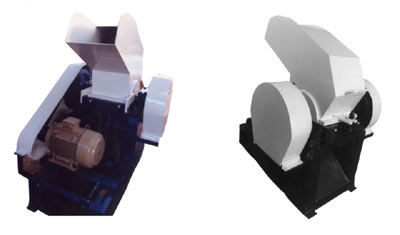

Pet Bottle Grinders

Hopper Feed Grinder(HBG-series)

Heavy duty welded/machined steel construction

Cross cut body design maximized rotor dia and output for same chamber size compared to horizontal cut body grinders. It laso provide easy access in side chamber for ease of blade change and maintanance.

Outboard mounted plummer - block heavy duty spherical roller bearings with K-type aleeve to prevent contaminations entering the bearings ,and K-sleeve makes it is to remove bearings for easy maintanance.

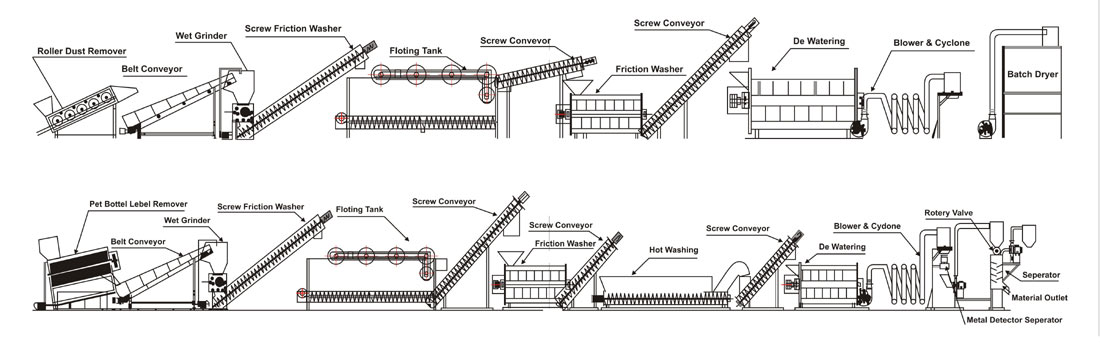

Pet Bottle Recycling Or Washing Line And Equipments

We provide state of the art world class PET Bottle washing lines in 500 & 1000 kg/hr capacity Best in class heavy duty high performance machines with latest configuration is capable of providing quality that is acceptable in various sector of application like Strapping/Fiber/POY and Bottle grade chips. We understand the need the customer and we can provide custom designed PET bottle wash lines as per customer's specific requirements.

We also provide individual equipments Like Bale opener, Screw conveyor Label stripper, Trommel, Bottle washer, Sorting conveyor, Grinders, Friction washers spin drayers, sink float tanks, hot wash reactors, hot air drayers, Air classifiers, neck separators etc.

Advance In Line Extrusion System For Soft Waste

Soft waste like film/raffia/fiber normally requires be densified and then feed to

extruder result in low quality and high energy consuption.

Our inline machine solve the problem by attaching centrifugal

force feeding system (which is choke free system compared to

conventional screw force feeds to extruders)special extruder

profile with double vaccum vent and mixing zones provide a

high quality product.