HITECH MACHINERY INDIA

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HITECH MACHINERY INDIA

Pouch Sealing Machine

Description / Specification of Pouch Sealing Machine

We are involved in offering a wide range of Pouch Sealing Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Pouch Sealing Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Ginger Garlic Paste Pouch Packing Machine

Fully automatic mechanically operated vertical pouch form, fill & seal machine to pack 'Viscous liquids' with exclusive design pneumatic piston filling system. Machine supported on heavy duty angular structure mounted on Castor wheel wrapped with stainless steel cabinet all contact parts are in stainless steel.

Technical Specifications:

- Feeding head: Pneumatic piston filling system.

- Production Speed: 30 - 35 sachets / min.

- Packing range: 50-150 ml/gm.

- Film Width: Up to 210 mm.

- Film Thickness: 60 to 80 microns.

- Film Material: Any heat sealable laminated film.

- Sealer heating system: Continues only.

- Filling Accuracy: +/- 3ml/gm.

- Inner Core Dia. of Film Roll: 70mm.

- Outer Dia. of the film Roll: Up to 350mm.

- Pouch Style: 3 or 4 side seal pillow pouch.

- Pouch Width: Up to 105 mm.

- Pouch Length: Up to 145 mm.

- Power Consumption: 1.2 kW / Hour.

- Peak Power: 3 kW.

- Air compressor: 2 Hp. 1 Phase, 230 V, AC 50 Hz.

- Air consumption: 4 CFM @ 20" C.

- Compressed air pressure: 6.5 kg/cm2

- Power requirement: Single Phase, 230 V, 50Hz.

- Pouch Counter: Provided.

- Date printing Device.: Optional.

- Machine Dimensions: 1500 (H) x 450 (W) x 450 (Depth).

- Net Weight: 350 to 450 kgs

Namkeen Pouch Packaging Machine

Namkeen Pouch Packaging Machine at reasonable prices. Set up with timer belt controlled by stepper motor drive, the offered compilation has an alphanumeric, LCD back lit display through micro controller based system. Vastly demanded by food processing and packaging industries, the range is quite reasonable.

Features:

- Consistent performance

- Tough construction

- Low power consumption

Applications:

- Irregular shaped products such as potato chips, extruded food, banana chips, cheese balls, bakery

- Products Homogenous fine grained products such as tea powder, seeds, sugar, whole spices

- Homogenous coarse grained products such as rice, wheat, pulses, Sabudana

- Coarse products such as cashew nuts, almond, pistachio, whole spices

- Mix products such as namkeen, farsan,

- Industrial products such as lugs, screws, nails, bolts, nuts etc.

- Specially suited for Poha ( Rice Flakes), Murmure, corn flakes, candies, etc.

- Pharma products such as capsules, tablets, etc.

Specifications:

- Feeding head: 2/4/6 Weigh Filling System.

- Production Speed: 08 to 10 pouches per min.

- Packing range: 50gm to 500 gm.

- Film Width: Upto 410mm.

- Film Thickness: 60 – 80 Microns

- Film Material: Laminated Film.

- Sealer heating system: Continuous / Pneumatic Type

- Inner Core Dia. of Film Roll: 70mm.

- Outer Dia. of the Film Roll: Upto 350mm.

- Pouch Style: Three Side / Four side sealing.

- Pouch Width: 400 mm. Max

- Pouch Length: 150 mm. Max

- Power Consumption: 1.5 KW / Hour.

- Machine Power: 3 KW.

- Power Requirement: 3 Phase, 415 V 50Hz.

- Machine Operation: PLC System

- Machine Dimensions: Basic Machine – 3.5 ft wide x 3.5 ft Length x 9.0 ft Height.

- Machine Gross weight: 350 to 450 Kg

Pickle Pouch Packing Machine

Description / Specification of Pickle Pouch Packing Machine

We are involved in offering a wide range of Pickle Pouch Packing Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Pickle Pouch Packing Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Spices Pouch Packing Machine

We are the leading manufacturer and supplier of Auger Filler Pouch Packing Machine or Automatic Collar Type Form Fill Seal Machine with Auger Fillers. It is an ideal pouch packaging machine with Servo operated Auger filler to pack various products at high speed like Flour, maize flour, custard powder, henna powder, Instant coffee powder, spices, milk powder, glucose powder, protein powder etc in center seal pillow type PP/ LDPE bags. our product are having such optional features like Controlled by PLC with color touch screen, AC Servo drive / AC Inverter drive for pulling paper, Self diagnostic, Easy loading of film roll.

Specifications:

• Filling Range: 50 gm to 1000 gm / 500 gm to 2000 gm Options:

• Servo driven Auger filler or clutch & brake driven auger filler

• Paper pulling option: Servo driven or through clutch & brake

Turmeric Powder Pouch Packing Machine

Description / Specification of Turmeric Powder Pouch Packing Machine

We are involved in offering a wide range of Turmeric Powder Pouch Packing Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Turmeric Powder Pouch Packing Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Fryums Pouch Packing Machine

Specifications:

- Feeding head: 2/4/6 Weigh Filling System.

- Production Speed: 08 to 10 pouches per min.

- Packing range: 50gm to 500 gm.

- Film Width: Upto 410mm.

- Film Thickness: 60 – 80 Microns

- Film Material: Laminated Film.

- Sealer heating system: Continuous / Pneumatic Type

- Inner Core Dia. of Film Roll: 70mm.

- Outer Dia. of the Film Roll: Upto 350mm.

- Pouch Style: Three Side / Four side sealing.

- Pouch Width: 400 mm. Max

- Pouch Length: 150 mm. Max

- Power Consumption: 1.5 KW / Hour.

- Machine Power: 3 KW.

- Power Requirement: 3 Phase, 415 V 50Hz.

- Machine Operation: PLC System

- Machine Dimensions: Basic Machine – 3.5 ft wide x 3.5 ft Length x 9.0 ft Height.

- Machine Gross weight: 350 to 450 Kg

Chilli Powder Pouch Packing Machine

Description / Specification of Chilli Powder Pouch Packing Machine

We are involved in offering a wide range of Chilli Powder Pouch Packing Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Chilli Powder Pouch Packing Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Banana Chips Pouch Packing Machine

Tachnical Specifications:

- Feeding head: 2/4/6 Weigh Filling System.

- Production Speed: 08 to 10 pouches per min.

- Packing range: 05gm to 100 gm.

- Film Width: Upto 410mm.

- Film Thickness: 60 – 80 Microns

- Film Material: Laminated Film.

- Sealer heating system: Continuous / Pneumatic Type

- Inner Core Dia. of Film Roll: 70mm.

- Outer Dia. of the Film Roll: Upto 350mm.

- Pouch Style: Three Side / Four side sealing.

- Pouch Width: 400 mm. Max

- Pouch Length: 150 mm. Max

- Power Consumption: 1.5 KW / Hour.

- Machine Power: 3 KW.

- Power Requirement: 3 Phase, 415 V 50Hz.

- Machine Operation: PLC System

- Machine Dimensions: Basic Machine – 3.5 ft wide x 3.5 ft Length x 9.0 ft Height.

- Machine Gross weight: 350 to 450 Kg

Semi Automatic Pickle Filling Machine

Description / Specification of Semi Automatic Pickle Filling Machine

We are involved in offering a wide range of Semi Automatic Pickle Filling Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Semi Automatic Pickle Filling Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Powder Filling And Sealing Machine

FFS Semi Pneumatic Auger Filler Machine Model No-FPA-500 is extensively used for packaging of varieties of namkeen, rice, pulses, sugar and food items.

FFS Pneumatic machine state of the art of technology comprises with most advanced features at economical cost to pack free flowing products in pouches.

F.F.S Machine

To furnish the diverse requirements of our clients we are involved in offering a wide range of FFS Machine. Our products are highly demanded in market due to their perfect finishing and rugged construction. Offered products are widely used in various industries for packaging of different items such as namkeens, chips and many others. Apart from this, we also assure to deliver a defect free range of our products in a specific time period.

Features:

• Highly demanded

• Best quality

• Timely delivery

Chips Packaging Machine

Description : Fully Automatic Collar Type machine with 2 linear weigh filler Machine

Specification :

• Filling range : 100gm to 500gm

• Speed : 15-16 pouch per minute (Depend upon Volume)

• Packing material : Heat sealable flexible laminated film

• Seal type : Center Seal

• Filling system : 2 HEAD

• Sealing system : Hot bar

• Electrical supply : 220V AC / Single Phase

• Power consumption: 3 KW

• Net Weight : 500 kg (Approx.)

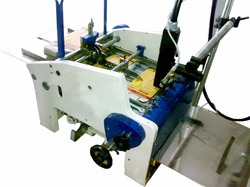

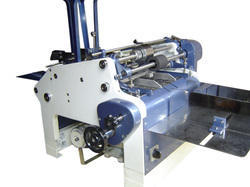

Horizontal Flow Wrap Machine

Horizontal Flow Wrap Packaging Machine Model No-HFW-150 used for packaging soap, bottle, stationery, bread, biscuit, cake, automobile parts, candy, chocolate, instant noodle, disposable syringe, our Horizontal Series Packaging Machine is demanded in the market due to its easy installation, sturdy structure and impeccable performance.

Semi Automatic Weigh Filler Machine

Semi Automatic Two Head Weigh Filler Machine Model No-SWF-50 is the packaging equipment used for packing various types of solid free flowing items. This packaging equipment is named as EASY PAC to emphasis its ease of operation. This packaging equipment is semi automatic packing machine which uses load cell to weigh the item & dispense it into the ready pouch/box/container, etc. As the pouch making machine is not the integral part of this packing equipment, it is categorized as the semi automatic packing machine. EASY Pac packaging machine can handle virtually all kind of free flowing solids. This packaging equipment handles grocery items such as rice, pulses, chana dal, toor dal, sugar, wheat, tea powder, green peas, white mutter & similar products without any change parts or making changes in the settings, one can keep on toggling with different materials & different target weights on the same packing machine. Technical Specifications : No of Heads One Two Three Four Feeding Method Through Linear Vibratory trays Weighing Range 3 gms to 1000 gms* ( limited by the volume of weighing pan) Speed (DPM) 3-8* 5-14* 8-20* 10-32* > Weighing accuracy 0.1 - 2% * Power Supply 230 V AC Power consumption 300 VA per head Utility Requirement Air Compressor for Weigh Pan Open/Close

Automatic Liquid Filling Machine

Automatic volumetric liquid filling machines are very useful for filing any free flowing thin or medium viscous liquid into any shape container/jars/bottles etc. It can be used in food, beverages, chemical, pharma & allied industries.

According to its applications machine are given below:

- Oil filling machine

- Juice filling machine

- Milk filling machine

- Syrup filling machine

- Hair oil filling machine

- Shampoo filling machine

- Gum filling machine

- Mouth freshener filling machine

Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose. The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum of time. The main drive consists of a helical gearbox driven by A/c motor & through controlled by an Ac frequency drive. The speed can be set in terms of bottles per minute. The conveyor drive consists of a hallow shaft, geared motor controlled by an Ac frequency drive. A knob can set the speed of conveyor

Salient Features:-

- ± 1 % Filling accuracy on single dose.

- No bottle No filling system.

- Rigid vibration free construction for trouble free performance.

- S.S. Elegantly matt finished body.

- Elegant and easy control panel for total control on operation.

- Minimum change overtime, from one size to another container or fill size.

- Self lubricating UHMW- PE guide profile for SS slat chain provides low friction wear surface, smooth and noiseless conveying.

- Drain tray around machine platform.

- Mechanical or Pneumatic bottle stopping arrangement.

- Synchronized two nos. A/C drives for main motor & conveyor belt.

Manual Liquid Filling Machine

Manual Liquid Filling Machine is a table top filling machine used for small scale industries, in laboratories, in R&D for filling volume 2ml to 250ml.

Salient Features:-

- Hand operated Volumetric Liquid Filling Machine is precision built on sturdy MS powder coated frame. Machine Works on volumetric principle.

- Piston is pumped by the handle provided to dispense the preset accurate volume of product.

- Volume can be set using the Volume setting bolt.

- Semi Automatic liquid filler with filling range from 2 ml to 250 ml with the help of change parts

- Accuracy ± 1 % in single doze.

- All contact parts SS316 & Body MS.

- Minimum change over time from one size to another container or fill size

Screw Capping Machine

Semi Automatic Screw Capping Machine Model No-SSC-50 The semi automatic Screw cap sealing machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine.

Require manually feeding & unloading container, where the body and the neck of the container are positioned below the rotating head and sealing head is performing perfect operation of sealing.

- The unit is made compact & versatile.

- S.S. Elegantly Matt Finished Body.

- Built in front control panel.

- Quick setting.

- Motorised head movement.

- No change parts require for different container diameter.

- Low noise level, low power consumptions.

- Adjustable bottle height gauge for easy and quick setting.

Capping Machines

Semi Automatic ROPP Capping Machine Model No-SRC-50 The semi automatic ROPP cap sealing machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine.

Require manually feeding & unloading container, where the body and the neck of the container are positioned below the rotating head and sealing head is performing perfect operation of sealing.

- The unit is made compact & versatile.

- S.S. Elegantly Matt Finished Body.

- Built in front control panel.

- Quick setting.

- Motorised head movement.

- No change parts require for different container diameter.

- Low noise level, low power consumptions.

- Adjustable bottle height gauge for easy and quick setting.

Automatic Capping Machine

Automatic ROPP Capping Machine Model No-ARC-50 is versatile, self-supported on stainless steel leg with height adjustable adjustment system. The machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are providing to facilitate the servicing of machine.

The feed container moving on conveyor belt are feed into an in-feed star wheel, bringing the container below the sealing head in the subsequent indexing part, mean while the rotating head pickup a cap from the cap star wheel which is receiving from delivery chute of cap filling bowl, where the body and the neck of the container are positioned below the rotating head, where the sealing head is performing perfect operation of sealing, rotating head is design to seal container according to pre-set torque

- No container no cap arrangement

- Single motor synchronizes conveyor, star wheel, & platform turret

- Adjustable height of conveyor belt

- All contact parts are made out of stainless steel

- Pick & Place arrangement

- Torque adjustable

- Low noise level, low power consumptions

Automatic Screw Capping Machine

Automatic Screw Capping Machine Model No-ASC-50 is versatile, self-supported on stainless steel leg with height adjustable adjustment system. The machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are providing to facilitate the servicing of machine.

The feed container moving on conveyor belt are feed into an in-feed star wheel, bringing the container below the sealing head in the subsequent indexing part, mean while the rotating head pickup a cap from the cap star wheel which is receiving from delivery chute of cap filling bowl, where the body and the neck of the container are positioned below the rotating head, where the sealing head is performing perfect operation of sealing, rotating head is design to seal container according to pre-set torque.

- No container no cap arrangement.

- Single motor synchronizes conveyor, star wheel, & platform turret.

- Adjustable height of conveyor belt.

- All contact parts are made out of stainless steel.

- Pick & Place arrangement.

- Torque adjustable.

- Low noise level, low power consumptions.

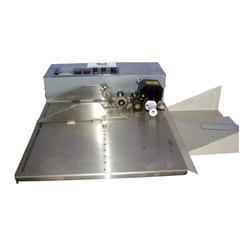

Induction Sealing Machine

Manual Portable Induction Sealing Machine Model MIS-100 Portable induction sealing machine utilizes electromagnetic induction principle to produce instant high heat to melt aluminum foil. Then it adheres to the bung hole, reaching the aim of wet-proof, leakage-proof, mildew-proof and extending preservation time. Now it is widely used as sealing package machine in industries such as pharmaceuticals, pesticides, pesticides, lubricant and cosmetics etc.

Continues Induction Sealing Machine

on line Induction Sealing Machine

Continues Induction Sealing Machine Model No-CIS-100 Induction sealing utilizes electromagnetic induction principle to produce instant high heat to melt aluminum foil. Then it adheres to the bung hole, reaching the aim of wet-proof, leakage-proof, mildew-proof and extending preservation time. Now it is widely used as sealing package machine in industries such as pharmaceuticals, pesticides, pesticides, lubricant and cosmetics etc.

On Line Induction Sealing Machine

Keeping in mind the diverse requirements if our clients we are involved in offering a wide range of On Line Induction Sealing Machine. These machines use electromagnetic induction principle for producing instant high heat to melt aluminum foil. Our products are precisely engineered by our professionals to ensure high durability and hassle free performance. We offer our products at affordable prices.

Features:

- Reliable

- Highly demanded

- Fine finish

Specifications:

- Supply Voltage: 220V/50-60Hz

- Out Put: 20-60pcs/min

- Sealing Diameter: 20-100mm

- Power: 2kw

- Machine weight: 150kg

- Machine size: W 760 X D 600 X H 1670mm

- Packaged Dimensions: 35”(875 mm) W X 29” (725mm) D X 72” (254mm) H

- Packaged Weight: 220kg

Induction Sealing Wads

These are made up of Glass, Polythene, LDPE, HDPE, PVC, PET and various other thermoplastics. These are suitable to be used with Child resistant, Snap on, Screw Type and many others closures as per the requirement of the clients. Ranging from small 50 ml. bottle to the big 200 Ltr. drums having neck size of 10 mm. and wide opening mouth of 200 mm diameter can be induction sealed with our range of wads.

Features:

- Preserves quality and purity of content

- Durable

- Prevent contamination

Vacuum Packing Machine

Vacuum chamber size : 465 Width x 440 Length x 80 mm Height. 100 Height mm optional

Over all Size : 415 x 490 x 350

Construction : Complete SS 304.

Lid : Transparent Acrylic or SS Dome optional.

Vacuum Pump : 20 cum

Gas Flushing : By default 4 nozzles.

Vacuum monitoring & control : German dial gauge, dial gauge & vacuum sensor optional

Electrical consumption : Maximum 2 KW can be operated on domestic connection.

Packing cycle : 2 to 3 Cycles/ minute depending upon the product to vacuum packed.

Hitech special :

• Maintenance free Vacuum actuator for lifting sealing bars.

• Fiber glass sealing bars for short circuit protection..

Carton Tapping Machine

Carton Tapping Machine is designed for closing (Sealing) uniform cartons (i.e. with same height and width) and is an excellent choice for any low to high volume closure needs. It widely used in home appliance, textile, food, general merchandise, medicine, and chemical.

The carton to be sealed is put on the in-feed rollers & given a gentle push, when the motorized conveyor takes over & starts pulling the carton forward. Here the top & bottom tape dispensers stick the BOPP type self adhesive tape onto the Top & Bottom flaps of the cartons simultaneously along with rollers pressing the tape for a tight seal. When the taping is over, the cutter blades cut-off the tape & the sealed cartons passes through to the out-feed rollers for delivery.

After the sealed box is discharged, it is ready for the next box. Also you can adjust the height and width for different cartons very easily.

- Up down movement of the sealing assembly is by manual hand rotary crank. Different Box sizes can be easily accommodated.

- EPOXY coated & Zinc plated taping heads with erect tape system & fully protected cutter blades provide smooth positive application of the tape on the Box.

- Interchangeable Top / Bottom Tape Cartridge.

- Tape overlap length can be adjusted from 55 mm to 75 mm.

- The machine is equipped with roller type working table, for smooth movement of boxes.

- Leg height adjustment by 240 mm.

- The system has side / double motor drive with automatic box centering & simultaneous box sealing from top/bottom.

- Box Conveying speed 20 mtr./min ensures High productivity.

- Simple in design & sturdy construction requires minimum maintenance.

Shrink Pack Machine

Shrink Tunnel Machine is put into the PVC sleeve & passed through the tunnel, the conveyor moves the product through the heat chamber and the finished, sealed product comes out from the other side.

Features & Specification:

- Adjustable Height.

- Variable Speed Roller (mesh) Conveyor

- Can be used at floor Height (Detachable Stand)

Box Strapping Machine

Box Strapping Machine to strap cartons, paper packages, wooden boxes, etc. using polyethylene plastic band which tightens & gets cut automatically. Carton Strapping Machine is suitable for strapping cartons of various heights very quickly without the need for bothersome strapping tools & metal seals. When you place the carton on the table & pass the strap around it, the strap self-tightens cuts & seals onto the carton automatically & is ready for the next carton.

•Simple Operation: Ergonomically designed control panel for easy operation. Strap at quick speed and with high efficiency. Only takes 1.5 seconds for strapping one polypropylene (PP) strap.

•Quick Heating: Instant-heating systems, low voltage of 1 V., high safety and will be in best strapping state in 5 seconds after you start the machine. Technical Specifications: Strapping Tension 5 to 60kg Strapping Size Min 60mm & Max Any Size Strap Width 6mm to 15mm Strapping Speed 2.0 Sec/Strap Power Supply 220Vac,1ph Power Consumption 0.4 KVA Machine Size L910 x W580 x H750 mm Machine Weight 80kg

Vacuum Packaging Machine

Floor Type Vacuum Packaging Machine Model No-FVP-400 Vacuum Packing Machines that revolutionize the way you store food. By storing food in a vacuum (which means without air), the shelf life for refrigerated, frozen and pantry foods is greatly increased. Air can cause food to become stale, fermented, dried out or develop freezer burn. Vacuum packing keeps your food fresher longer. For use in packaging of fish and meat products, cashew nuts, dry fruits, tea, sensitive electronic components, electrodes, etc.

Snacks Packing Machine

Automatic Weigh Filler Machine at reasonable prices. Set up with timer belt controlled by stepper motor drive, the offered compilation has an alphanumeric, LCD back lit display through micro controller based system. Vastly demanded by food processing and packaging industries, the range is quite reasonable.

Features:

- Consistent performance

- Tough construction

- Low power consumption

Applications:

- Irregular shaped products such as potato chips, extruded food, banana chips, cheese balls, bakery

- Products Homogenous fine grained products such as tea powder, seeds, sugar, whole spices

- Homogenous coarse grained products such as rice, wheat, pulses, Sabudana

- Coarse products such as cashew nuts, almond, pistachio, whole spices

- Mix products such as namkeen, farsan,

- Industrial products such as lugs, screws, nails, bolts, nuts etc.

- Specially suited for Poha ( Rice Flakes), Murmure, corn flakes, candies, etc.

- Pharma products such as capsules, tablets, etc.

Sealing Machine

Continuous Bag Sealing Machine Model No-CBS-100 Continuous pouch sealing machine is used for high speed bag sealing, bag sealing machine are available in different modal vertical bag sealing machine, horizontal bag sealing machine. This machine required nitrogen cylinder. This machine you can seal 5kg to 10kg material it’s used for packing cheeps, wafer, and confectionery item. Any material you can seal easily like LD.PP, BOPP & Laminated pouch. These machines are continuous sealers useful for Laminated BOPP, Led Aluminum, P. P. HM. etc. Feature: • Suitable for sealing all kind of Plastic films. • Sealing length is unlimited. • Reliable sealing quality. • Compaq design & can use. Optional: • Nitrogen Flushing Attachment Specifications: Sealing Width 12mm Sealing Speed 8-9 meter / minute Max Conveyor Load 30 Kg Teflon Belt Length 1000mm Conveyor Belt Width 200 mm Conveyor Belt Length 2600mm Conveyor Height Adjustable for easy Body Material MS with powder coated. Heating Jaw Brass Material Heater 230 volts tubular heaters(140mm) Temperature Digital Temperature controller (PID) Motor 1/4 HP Single Phase Dimension(L x W x H)(mm) 1350(L) x 525(W) x 1515(H) Type of Sealing Diamond Sealing Approx. weight 180kg. Type of Material PP, LD, BOPP, Laminated Pouch, Metallic Pouch

Pouch Sealing Machines

To furnish the diverse requirements of our clients we are involved in offering a wide range of Pouch Sealing Machine. These are widely used for sealing of pouches in industries of various sizes. Offered products are highly reckoned among our clients due to their hassle free performance and durable nature. We offer these products at market leading rates to our valuable clients. Features: • Abrasion resistant • High quality • Completely tested Specifications: Model No CPM-500 H Sealing speed 8mtrs per minute Sealing Width 5mm, 8mm, 12mm or as per requirement Film All Laminated film Film Thickness 0.02-0, 0.25mm Heater 200w x 2 (Cartridge type, easy to replace) Cooling System Fan Air cooling Temperature Controller Digital Temperature Controller 50° C to 300° C Electricity 1.5kw, single phase, 220 to 230 V Type Vertical Conveyor Size 200mm width, 1650mm length Dimension Length 1750mm, Width 500mm. Height 1 mtr. Net Weight 80 kg Optional Attachment Nitrogen Flushing Attachment

Continuous Sealing Machine

Continuous Bag Sealing Machine Model No-CBS-50 Continuous pouch sealing machine used for high speed bag sealing, bag sealing machine are available in different modal vertical bag sealing machine, horizontal bag sealing machine. This machine required nitrogen cylinder

This machine you can seal 25kg to 50kg material it’s used for packing cheeps, wafer, and confectionery item. Any material you can seal easily like LD.PP, BOPP & Laminated pouch. These machines are continuous sealers useful for Laminated BOPP, Led Aluminum, P. P. HM. etc.

Feature:

- Suitable for sealing all kind of Plastic films.

- Sealing length is unlimited.

- Reliable sealing quality.

- Compaq design & can use.

Optional:

Nitrogen Flushing Attachment

Handy Induction Sealing Machine.

Description / Specification of Handy Induction Sealing Machine.

We are involved in offering a wide range of Handy Induction Sealing Machine. to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Handy Induction Sealing Machine.. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Pouch Sealing Machine With Nitrogen Flashing Attachment

Pouch Sealing Machine. Our products are manufactured using superior quality material which we sourced from the certified vendors of the market. These are widely used for packaging of various items in many industries such as food, pharmaceuticals and many more. Additionally, these can be availed at industry leading prices via easy payment modes.

Features:

• Cost effective

• Quality approved

• Fine finish

Manual Portable Induction Sealing Machine

Specifications:

• Supply Voltage: 220V/50-60Hz

• Out Put: 20-40pcs/min

• Sealing Diameter: 20-100mm

• Power: 500W

• Machine weight: 6kg

• Machine size: L 340 X W 90 X H 150mm

• Packaged Dimensions: 21”(533 mm X 19” (483mm) X 10” (254mm)

• Packaged Weight: 8kg

Continues Pouch Sealing Machine

Specifications:

• Power Supply: 230 VDC,50 Hz

• Consumption: 500W

• Sealing Speed: 0 to 12 miter Per Min

• Sealing Width: 6 to 15 mm

• Film Thickness: 0.02 to 0.8 micron

• Temp Range: 0 to 300???C

• Conveyor Load: 5kg

• Machine Size: 900 X 480 X 380

• Machine Weight: 35kg

Tube Filling Machine

Semi Automatic Tube Filling Machine Model No-STFM-40 A syringe pump housing and rotary piston filling device that has a blow off device pneumatic tail cut-off system. These machines have a high filling speed of 40 to 50 tubes per minutes and jacketed hopper single head type of capacity of 40 litters. These tube filling machines are provided with stainless steel spring loaded change part 12 nos. nylon holders one tube size. These machines are also equipped with temperature controller with 3 KW SS tubular heater. Our range of machines have a label sensor and controller and various optional accessories like vacuum cleaning, jacketed hopper with stirrer, product level sensor in filling hopper with pump controller, automatic cassette loader to load the tubes and orientation sensors with stepper motor.

Salient Features:

- Semi Automatic Lami/Plastic Tube Filling machine, with have high operating speed and 12 Stations compact rotary.

- filling from 5 gm to 150gm

- Its contact parts are manufactured using quality stainless steel of grades 316

- These machines are no tube - no fill device, with a bottom up filling system and filling accuracy +/ - 0.1%.

- These machines have a tube diameter of 16-60mm and height 60-258mm

- The tube holding Cup is manufactured using quality stainless steel of grade 304.

- 8. Manifold cam indexing device Make Cam filed.

- Geared Motor 0.5 HP, RPM-40 REMI make

- Belt Less Stirrer Device with augur to keep the product in Continuous homogeneous condition.

Automatic Tube Filling Machine

Fully Automatic Lami and Plastic Tube Filling / Sealing / Coding and Cutting Machine Model No-ATF-150

Salient Features:-

- Semi Automatic Lami/Plastic Tube Filling machine, with have high operating speed and 12 Stations compact rotary.

- filling from 5 gm to 150gm

- Its contact parts are manufactured using quality stainless steel of grades 316

- These machines are no tube - no fill device, with a bottom up filling system and filling accuracy +/ - 0.1%.

- These machines have a tube diameter of 16-60mm and height 60-258mm

- The tube holding Cup is manufactured using quality stainless steel of grade 304.

- 8. Manifold cam indexing device Make Cam filed.

- Geared Motor 0.5 HP, RPM-40 REMI make

- Belt Less Stirrer Device with augur to keep the product in Continuous homogeneous condition

Optional Accessories:

- Sealing & Crimping Types: Hot air/ hot jaw / ultrasonic’s, double triple & saddle type fold for metal tubes.

- Jacketed hopper & stirrer.

- Batch Coating Arrangement [Male or Female] Type is also provided.

- Transfers Pumps.

- Tube cleaning Attachment.

- Technical Specification:-

- Output 40 to 45 Tube/per min

- Filling Range 5 gm to 150 gm

- Tube Diameter 10 mm to 50 mm

- Power Consumption 5kw

- Air Pressure 6 to 7 kg

- Net weight 450kg

- Gross Weight 555 kg

- Dimension 38"L x 36"W x 72"H

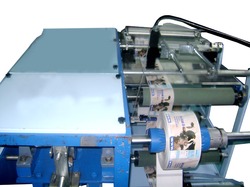

Winder Rewinder Machine

Winder Rewinder Machine for Ink Jet Printer Model No-WR-450, Suitable for high precision marking & coding system for Roll form printing material like polyester film, Glassine poly, Alu - foil, paper & laminated film with Hydraulic web control and alignment system. Also, it is used widely for on-line printing of Mfg. Dt., Exp. Dt., B. No., etc. using Ink-Jet Printer (Model A220+) or other contact coding machines Model OBC-35 from Roll to Roll at high speeds & then these printed rolls are used in the various packaging machines.

• Cantilever design balancing body for easy loading and unloading of parent / rewound reel

• Movable unwind Stage for Edge Guiding System (Web Aligner)

• Mechanical 1.5 / 2.5 Kg Magnetic Powder Brake with Tension Controller, Torque Control potentiometer & On-Off switch

• SS 316 made master inspection table with bracket

• Provision for incorporating Ink Jet Printing System

• Provision to mount Inkjet print head, shaft encoder and eye mark sensor (for Any make Inkjet Coder)

• Hydraulic Web Aligner Unit Technical Specification: Max Web Width 450 mm Unwind Reel Dia (Max) 450 mm Rewind Reel Dia (Max) 450 mm Speed (Max) 150 mtrs/min Core ID 76 mm Electric Motor 2 HP

Carton Stacker Coder

High Speed Labels, Pouches & Cartons feeding unit. Also, it is used widely for on-line printing of Mfg. Dt., Exp. Dt., B. No., etc. using Ink-Jet Printer (Model A120+/A200+& A220)

Technical Specifications:

- Carton Size: Min 75 X50mm Max 300 X165mm

- Supply Voltage: 3 phase 440Vac ±10% 180W

- Printing On: Ink Jet Printer

- Printing Speed: 125/180/250 per Min

- Motor: 440 Vac 3 phase ¼ H.P 136 Rpm

- Machine Size: L 870 X W 765 X H 625mm

- Machine Weight: 125 kg Net/175 kg Gross (Approx)

Conveyor

These Conveyors are used for carrying products from filling to packing destinations and various other applications as per requirement. Application: Various kind of products bottle, can, pouch, jar, labels, boxes etc. using Ink-Jet Printer (Model A120+/A200+& A220)

Salient Features:

•Compact and robust machine.

•Very simplified operation and almost zero maintenance, easy cleaning.

•With adjustable side support on both side to guide the product.

•Option available for adjustable speed. Technical Specification: Conveyor Length 1500 mm (60”) Conveyor With 200 mm (8”) Conveyor Height 900 mm (24”) Feeding Material Bottle, Can ,Jar, Labels, Carton etc Power 230 Vac 1 phase 50 Hz/ 1500 W

Batch Printing Machine

Coding Machine on Line Registered Batch Coder Model No-OBC-35 Fully automatic PLC based coding system for on-line registered printing of B.No., Mfg.Dt., Exp.Dt., M.R.P. Rs.,etc. on continuous & intermittent FFS (Form Fill Seal) machines, pouch packing / flow wrapping / blister pack machines, biscuit / masala / oil / milk / water packing, conveyor systems, winder-rewinder system, etc • Online Registered Coding. No need to stop the process for printing as printing is on-line and continuous at very high printing / production speeds up to 350 impressions / minute. Technical Specification: Supply Voltage 230 Vac ± 10 % 15 VA 5 VA Printing Area 4 lines (35mm x 200 mm) Printing Speed Max. 30 Meters/min Printing Using Easily Changeable grooved/flat rubber/nylon stereos Inking Medium Special rechargeable ink cartridge / wax cartridge Printing Medium Quick drying ink (Black, Violet, Red, Green, White*, etc) Printing Impressions 15,000 per 25 ml. Charge

Batch Coding Machine

Batch Printing Machine Technical Specifications: Supply Voltage 230 Vac ± 10 % 15 VA 5 VA Printing Area 4 to 6 lines (35mm x 35 mm) Printing Speed Max. 80 imprints/min Printing Using Easily Changeable grooved/flat rubber/nylon stereos Inking Medium Special rechargeable ink cartridge / wax cartridge Printing Medium Quick drying Ink (Black, Violet, Red, Green, White*, etc) Printing Impressions 15,000 per 25 ml. Charge Machine Weight 7 kgs, 3kgs (Only Head)

Table Top Label Carton Stacking Coder

This coder is ideal for Automatic High Speed Coding on large quantities of labels & cartons. It delivers high quality multi-line printing at production speeds upto 300 impressions or pieces / minute. Technical Specification: Supply Voltage 30 Vac ± 10%, 180 W Substrate Labels / Cartons Substrate size 40 X 20 mm to 200 X 380 mm Printing Area Max. 5 lines 10 letters per line (35 mm X 60 mm) Printing Speed Max. 300 imprints / min. using stepping clutch. Prints using Easily Changeable Brass / Copper stereos 2/2.5/3 mm Printing Medium Instant drying wax ink (Black, Blue, Red*, White*, etc.) Inking Medium Instant dry thermo-fusible hot wax ink roll. Impressions Appx. 1, 00,000 per 32-mm. replaceable cartridge. Size / Weight 440 mm L X 340 mm W X 260 mm H / 30 Kgs

Label Stacker Coder

Label Pouch Carton Stacking High Speed Coder Model No-LPC-300

Features:

Fully automatic labels, Pouches & Cartons feeding unit, easy controls, nice and quick adjustments, accurate registration, uniform neat and clean printing, compact size, counting arrangement (optional), high speed

Suitable for high-speed multi-line printing on most types of Labels/Pouches & Cartons as in the Oscillating distributor roller spreads ink evenly to the ink roll to obtain uniform printing at the exact desired location

Carton Coding Machine

Carton Stacking High Speed Coder Model No-CSC-300

Features:

- Fully automatic Cartons feeding unit, easy controls, nice and quick adjustments, accurate registration, uniform neat and clean printing, compact size, counting arrangement (optional), high speed.

- Suitable for high-speed multi-line printing on most types of Cartons as in the Oscillating distributor roller spreads ink evenly to the ink roll to obtain uniform printing at the exact desired location

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.