HITECH FIBRE GLASS MATTINGS P.LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HITECH FIBRE GLASS MATTINGS P.LTD

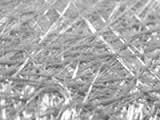

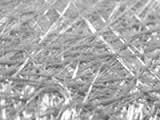

Chop Strand Mat

Chop Strand Mats (CSM) Manufactured by Hi-Tech uses best quality E-Glass Rovings. German Plant ensures perfect dispersion and even distribution of Chop Strands. Stitch Bonded CSM meets all requirements of IS 11551/BS3496.

Rovings Type of Glass E-Glass

Type of Roving Multi end - Chopping

Filament Dia 12 - 13 µ

Coupling Agent Silane

Resin Compatibility Polyester / Epoxy

Rovings Tex 2400 +/- 120

CSM Strand Length 50 mm

Avg. Mass / Unit Area (gr/m2) 300, 450, 600, 1000, 1400 +/- 10%

Width ( Ends Trimmed ) 1000, 1250, 1500 mm

Moisture Content 0.5% max.

Loss on Ignition 2% to 5% based on GSM

Binder Polyester Yarn 10 to 20 Gr/m2 based on GSM

Denier / Tex 85 Denier

Stitching Tricot, Length - 3.5mm, 7 stitches / Inch

Packing Paper Core 76 mm ID, 86 mm OD

Polythene Bag 250 g

Lenght, weight / rolls, carton As per customer requirement.

Applications

Boat Building and other Marine Applications

Prefabricated Shelters/Car Sheds

Structural Section

Telephone and Security Cabins

Crash Helmet, Laminates, Panels

Electric Poles, Pipes, Claddings, Railway Carriage Bodies, Parts and sleepers

Automotive Parts

Processes

RTM

Pultrusion

Compression Moulding

Centrifugal Moulding

and Hand Lay-Up

Advantages

Prevents Fibrewash

Rapid Wetout (No Binder)

Good Drapability

Uniform Thickness.

Uniform Mechanical strength

Wide Range

Combination Mat

Combination mats manufactured by Hi-tech uses best quality E-Glass Rovings and woven Rovings (WR) in various GSM. Chop Strands are uniformly disturbuted in random orientation and firmly held together with WR by Stitch Binding. Both Woven Rovings and Rovings used in Combination Mats confirms to international standards.

Woven Rovings Avg.Mass / Unit Area 360, 600 Gr/m2 +/- 10%

Type of Glass E-Glass,

Resin Compatibility Polyester / Epoxy

Roving / Tex Type 30 - 600 Tex, 1200 Tex

Construction - EWR 360 Warp 600 Tex X 320 +/- 10% per mtr.

Weft 600 Tex X 280 +/- 10% per mtr.

Construction - EWR 600 Warp 1200 Tex X 275 +/- 10% per mtr.

Weft 1200 Tex X 236 +/- 10% per mtr.

Type of Weaving Plain Weaved 0,90 Degree

Chopped Strands Avg. Mass / Uint Area 300, 450 Gr / m2 +/- 10%

Width ( Ends Trimmed ) 1000, 1250, 1500 mm

Type of Glass E-Glass, Silane Sized

Fibre Length 50 mm

Resin Compatibility Polyester

Binder Polyester Yarn 15 to 20 Gr/m2 +/- 5%

Denier / Tex 85 Denier

Stitching - Type Tricot, Length - 3.5mm, 7 stitches / Inch

Combination Mat Avg. Mass / Uint Area 660, 900, 1050 Gr/m2 +/- 10%

Moisture Content 0.50 % Max

Loss on Ignition 2% to 3%.

Width 1.0 mtr

Length and weight / roll As per customer requirement.

Packing Wound on paper core.

Applications

Boat Building and other Marine Applications

Prefabricated Shelters/Car Sheds

Structural Section

Telephone and Security Cabins

Crash Helmet, Laminates, Panels

Electric Poles, Pipes, Claddings, Railway Carriage Bodies, Parts and sleepers

Automotive Parts

Processes

RTM

Pultrusion

Compression Moulding

Centrifugal Moulding

and Hand Lay-Up

Advantages

Prevents Fibrewash

Rapid Wetout (No Binder)

Good Drapability

Uniform Thickness.

Uniform Mechanical strength

Wide Range

Sandwich Mat

Sandwich Mat is a 3 layer Composite Mat, consists of Synthetic Non Woven Core in the centre, Chop Strands on both sides . All the three layers are firmly held together by stitch binding. The technical details are as under :

First Layer Chop Strands 300 / 450 / 600 gr/m2 +/- 10%

Type of Glass E-Glass,

Fibre Length 50 mm

Resin Compatibility Polyster / Epoxy

Middle Layer PP Non Woven 180 gr/m2 +/- 10%

Third Layer Chop Strands 300 / 450 / 600 gr/m2 +/- 10%

Type of Glass E-Glass,

Fibre Length 50 mm

Resin Compatibility Polyster / Epoxy

Binder Polyester Yarn 15 to 25 gr/m2

Denier 85 Denier

Stitching - Pattern Tricot

- Length 3 to 5 mm

- Guage 7 (stitches / inch )

Sandwich Mat Avg. Mass / Uint Area 780, 1080, 1380 gr/m2 +/- 10%

Moisture Content 0.20 % Max

Width 1.0 mtr

Lenght / Roll As per customer requirement.

Weight / Cartons As per customer requirement

Packing Wrapped on Paper Core of 76mm ID, 86mm OD, Polythene Bag, Corrugated Cartons.

Note:

1. Third layer can also be WR 360 or 600

2. F.G Surface

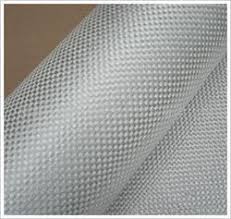

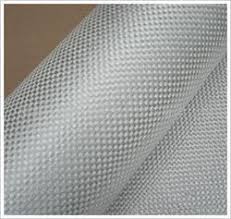

Woven Roving

Hi-Tech Woven Rovings are Bi-Directional – plain weaved (00, 900) and are manufactured using best quality Single End / Direct Rovings. These Woven Rovings are compatible with polyester and epoxy resins systems.

Product Range and Technical Data

Product EWR 360 EWR 600 EWR 800

GSM(grms/m2) 360 + 10% 600 + 10%/td> 800 + 10%

Width 1000 mm + 10 mm 1000 mm + 10 mm 1000 mm + 10 mm

Construction

Roving Tex

Warp Ends / mtr

Weft Ends / mtr

600

320

280

1200

275

236

2400

177

157

Thickness 0.45 mm + 10% 0.60 mm + 10% 0.80 + 10%

Width does not include selvages which will be about 2 cm.

Moisture content 0.15% Max.

Packing – Paper Core ID – 75mm, OD – 85mm, Poly Bag and Corrugated Cartons.

Applications

Boat Building

tanks

pipes

Garden Slides

and many others

where high mechanical properties are required.

Fiberglass Stitch Bonded Mats

Description / Specification of Fiberglass Stitch Bonded Mats

We are involved in offering a wide range of Fiberglass Stitch Bonded Mats to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Fiberglass Stitch Bonded Mats. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.