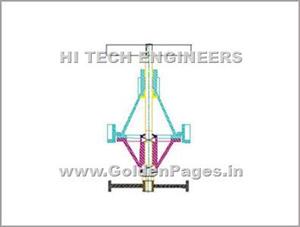

HI TECH ENGINEERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HI TECH ENGINEERS

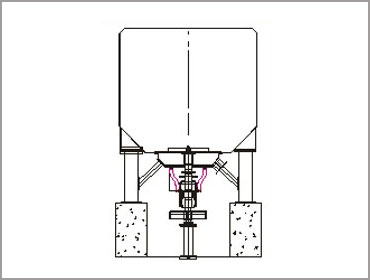

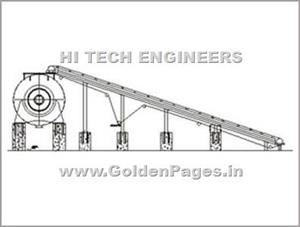

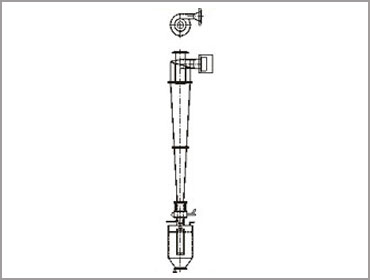

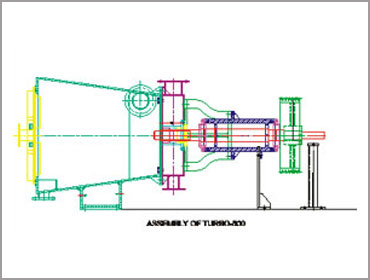

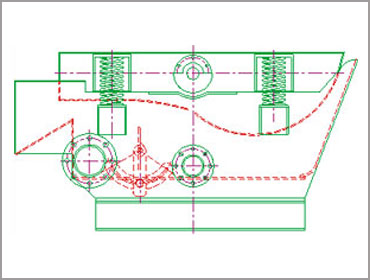

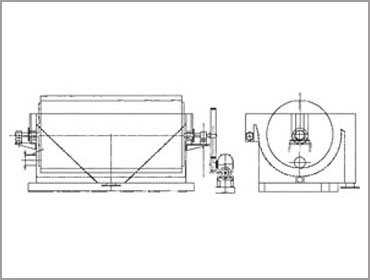

Press Section

The highest possible dryness should be reached with least possible number of nips.

Pressing must not impact paper quality.

The press section should compact, Simple and rigid Structure.

Hydraulic & Pneumatically loaded press rolls with heavy duty framing.

Press section is designed for 180kg. - liner cm. load for efficient water removal.

It is double felted first nip for two sided dewatering used for higher efficiency of press.

Heavy duty press section with roll dia 430 to 1200 mm.

For high speed application grooved or blind-drilled roll is available.

Large diameter presses at high press load combine optimum performance with low investment, operation and maintenance cost.

Production increase, reduced steam consumption and efficiency increases in case of rebuilt of an exciting machine.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.