HINDUSTAN COMPOSITES LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HINDUSTAN COMPOSITES LTD.

Automotive Brake Linings

Catering to the needs of vehicle manufacturers and consumers in India and abroad, HCL has a wide range of asbestos - free and asbestos based automotive brake linings. The heavy duty brake linings find application in commercial vehicles including Tata, Leyland, Mercedes Benz, Volvo, Scania, and other widely accepted international vehicles. Its brake linings and disc brake pads are also used in light commercial vehicles and two-wheelers.

Automotive Roll Linings

Catering to the needs of vehicle manufacturers and consumers in India and abroad, HCL has introduced a wide range of asbestos - free and asbestos automotive roll linings. The heavy duty brake linings find application in commercial vehicles including Tata, Leyland, Mercedes Benz, Volvo, Scania, and widely accepted for other international vehicles. Its brake linings and disc brake pads are also used in light commercial vehicles and two-wheelers.

Automotive Clutch Facings And Ceramic Buttons

HCL meets the demand of moulded and random woven clutch facings for all Indian and most international vehicles including passenger cars and light commercial vehicles. These are manufactured in state-of-the-art manufacturing facility with technology acquired from Bendix Mintex Pty Ltd., Australia.

Automotive Disc Brake Pads

Catering to the needs of vehicle manufacturers and consumers in India and abroad, HCL has a wide range of asbestos - free and asbestos automotive brake linings, clutch facings, and disc brake pads. The heavy duty brake linings find application in commercial vehicles including Tata, Leyland, Mercedes Benz, Volvo, Scania, and widely accepted for other international vehicles. Its brake linings and disc brake pads are also used in light commercial vehicles and two-wheelers.

Railway Brake Blocks

Compo C/BB/K brake block is a rigid moulded friction material, grey-black in colour, having a random fibre asbestos base and containing metallic particles. It is manufactured only in the form of brake blocks, integrally moulded to a back plate. This material was originally developed to have the ability to withstand the heavy braking demands of Electric Multiple Unit (EMU) stock, operating suburban passenger services. Its use has since been extended to a range of duties from low speed shunting locomotives to high speed passenger trains.

Friction Sheets

HCL manufactures rigid moulded and woven friction sheets with and without wire reinforcement or metallic inclusions. These are used as segments in industrial clutches, marine gearbox clutches, tractor steering clutches, power press clutches, industrial brakes and other general engineering requirements in shipping, mining, port related and other industries.

Industrial Roll Linings

Industrial woven and flexible roll linings with and without wire reinforcement in various thickness and lengths are another speciality of HCL. Their applications are in segments or as band brakes in elevators, cranes, winches, hoists, drop hammers, concrete mixers, heavy earth moving equipment and in dry and oil immersed conditions.

Millboard Sheets

This is a versatile thermal insulation and heat resistant material produced in sheet form using good quality fibres incombustible fillers and vegetable binders. It dose not suffer loss of strength upto 485°C. When suitably supported the board can be used satisfactorily at extreme temperatures upto approx. 1400°C.

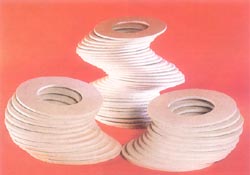

Millboard Discs

The heat resistant discs are made from materials containing a higher percentage and a small quantity of organic binder, to withstand the application temperature exceeding 1000C.

Service

Recommended for making up a solid block of supporting internal and external rollers in steel & glass plants. The discs possess adequate physical strength to withstand the machining operations to achieve a mirror finish.

Compestos

Compestos

Asbestos laminated sheets are moulded from asbestos cloth with thermosetting resins and are specially developed for engineering applications. The high content of asbestos, superior grade of binder and special press-curing techniques impart high degree of mechanical strength. These materials are hard wearing, heat resistant and unaffected by a wide range of chemicals and solvents.

Special Characteristics

Compestos materials do not require specials lubricants. They are compatible with water emulsions, many chemicals and normal lubricating oils, grease, compounds, molybdenum di-sulphide paste etc.

Compestos materials are characterised by the following outstanding properties

Excellent dimensional stability

Good wear and chemical resistance

Low moisture absorption

Very high strength to weight ratio

High temperature resistance

High impact resistance

Excellent irradiation characteristics

Impervious to effects of moisture of marine exposure

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.