HEAT SOURCE

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HEAT SOURCE

Ceramic Sealed Infrared Heaters

- Medium wavelength radiation.

- The most preferred source of heat when rapid heater response is needed.

- The heaters are comprises of a series of quartz tubes running parallel to each other within a highly reflective steel housing.

- Watt densities up to 30 w / in.2 (46.5 kw / m)2.

Quartz Infrared Heating Elements

- Medium wavelength radiation.

- he most preferred source of heat when rapid heater response is needed.

- he heaters are comprises of a series of quartz tubes running parallel to each other within a highly reflective steel housing.

- att densities up to 30 w/in.2 ( 46.5 kw/m)2

Short Wave Infrared Heaters

Infrared heat is transmitted directly in the form of electromagnetic rays, at a velocity of approx. 300,000 km/sec i.e. at the speed of light.

IR is therefore not only the "fastest form of heat", but is also suitable for particularly demanding applications such as vacuum technology and clean room conditions.

Infrared heat is particularly economical on energy compared to other heat sources because it acts quickly, directly on product.

Short Wave IR emitters are suitable for all applications in which the attainment of high temperatures in the shortest possible time is what counts.

Short Wave I.R Heaters

|

Twin Tube Infrared Heaters

QUARTZ GLASS

The quartz glass is very pure and provides good transmission and temperature resistance.

TWIN TUBE

The unique twin tube design offers high radiation power and very good mechanical stability allowing emitters of lengths up to 3.5 meters. Emitters are available in Short Wove, Medium Wave, or Long Wave versions. That gives you the possibility to select the optimum wavelength for the material to bo hooted. Dimensions and filaments are matched to requirements.

GOLD/WHITE COATED

Twin Tube Infrared Heater is made by virtue of a gold & white coated which con emit heat directly to the product. A coating on the infrared emitters reflects the infrared radiation. Consequently the infrared radiation impinging on the product is virtually doubled.

Rod Type Finned Heaters

APPLICATION

This heater is used in air heating with maximum surface area. This can be used in ovens & dryers.

ADVANTAGES

It consists of easily replaceable heating elements, which are cheap in the long run. Where perishable heating Gils can be replaced easily old sheath can be re-used.

Duct Heaters

APPLICATION

This type of heater is used where forced hot air is required through smaller ducts of ovens, dryers, hot air blast, space heating etc.

CONSTRUCTION

Pairs of tubular (with - w/o finns) heaters are mounted in a chamber with easy to replace facility. Complete with terminal cover on the top or side isolated from the heating zone

S.S Strip Finned Heaters

|

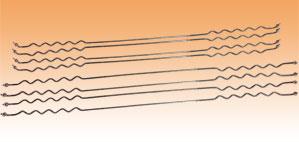

Tubular Zig Zag Air Heaters

|

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.