Infrared heat is transmitted directly in the form of electromagnetic rays, at a velocity of approx. 300,000 km/sec i.e. at the speed of light.

IR is therefore not only the "fastest form of heat", but is also suitable for particularly demanding applications such as vacuum technology and clean room conditions.

Infrared heat is particularly economical on energy compared to other heat sources because it acts quickly, directly on product.

Short Wave IR emitters are suitable for all applications in which the attainment of high temperatures in the shortest possible time is what counts.

|

QUARTZ GLASS

The quartz glass is very pure and provides good transmission and temperature resistance.

TWIN TUBE

The unique twin tube design offers high radiation power and very good mechanical stability allowing emitters of lengths up to 3.5 meters. Emitters are available in Short Wove, Medium Wave, or Long Wave versions. That gives you the possibility to select the optimum wavelength for the material to bo hooted. Dimensions and filaments are matched to requirements.

GOLD/WHITE COATED

Twin Tube Infrared Heater is made by virtue of a gold & white coated which con emit heat directly to the product. A coating on the infrared emitters reflects the infrared radiation. Consequently the infrared radiation impinging on the product is virtually doubled.

APPLICATION

This heater is used in air heating with maximum surface area. This can be used in ovens & dryers.

ADVANTAGES

It consists of easily replaceable heating elements, which are cheap in the long run. Where perishable heating Gils can be replaced easily old sheath can be re-used.

APPLICATION

This type of heater is used where forced hot air is required through smaller ducts of ovens, dryers, hot air blast, space heating etc.

CONSTRUCTION

Pairs of tubular (with - w/o finns) heaters are mounted in a chamber with easy to replace facility. Complete with terminal cover on the top or side isolated from the heating zone

|

|

ADVANTAGES »

Sheathing heavy gauge, s.s., titanium, m.s., or lead bonded tube with closed bottom with flange (for vertical operation), or checknut (for horizontal operation), welded on the top. Checknut will have the threadings of 1.5” BSPT or 2” BSPT or 2.5” BSPT suitable to the ordered size. It is available in easy to replace the coil system. Unscrewing the top terminal plate can easily stretch the element out.

To Heat dies & moulds, Smelting of materials, heating of fluids & heat welding etc. HD cartridge heaters are able to with-stand the toughest working conditions such as vibration, moisture, fluids, spills, frequent expansions & where the temp. Is 400 to 750 Deg. C. are required, or temperatures within a limited space.

High-wattage cartridges belong to a new generation of electric heat-ing elements; they make it possible to use high watt loads in small spaces, thus ensuring excellent reliability in heavy-duty work condi-tions. Their special construction technology makes them the most advanced type of heating elements. The entire length of the wire wound around a magnesium oxide core is in a far away position from the axis of the cartridge, very close to the metal sheath, with a very thin and compressed insulating wall in between; this allows excellent heat exchange that allows a much lower temperature of the resis-tance wire than in other heaters in which the wire is in a deeper posi-tion. Besides the use of advanced technology and precise inspection techniques in their manufacturing.

|

|

APPLICATION

To heat up water, oils, chemicals pre-heating cleaning solutions baths.

CONSTRUCTION

Sheathing-Tubular elements are sheathed in S.S., copper monel, incoloy etc., suitable to various applications. The elements are of ‘U’ shaped welded with flange or checknut for vertical or horizontal operation resp. Check-nut fiange is made out of brass, m.s. or s.s. Heating element - helical wire wound coil is inserted into the tube with uniform pitches and rigidly tightened by insulation powder complete with brazed terminals.

APPLICATION

To heat-up various acidic solutions where no metal withstands. Generally this heater is used in electroplating industries. The heater is operated vertically only.

CONSTRUCTION

Sheathing–This type of heaters have quartz silica tube sheathing, closed from bottom. Rubber cap with terminal wires are mounted on the top. Heater terminals are fixed very firmly with the outer wires. It consist of non-sinkable heating element, as the heater is suitable for vertical installation only.

APPLICATION

Open Cartridge Heaters are widely used as immersion heaters or as air heater selecting appropriate sheath materials for heating various types of chemicals,oils & water OR air & gases.

CONSTRUCTION

They are available in various diameters and lengths as per customers' specifications. However the standard diameters are from 8 mm OD to 75 mm OD. They can be designed for vertical as well as horizontal installation with required heating and non-heating zones.

To heat up dies & moulds, where uniform & quicker heat is required, and where more surface are to be covered. To heat dies & moulds, where temp above 400C. is required (max. upto 450C.), more surface area to be covered & quicker heat is required.

Basically this heater is tubular type, with higher watt density & covers & being casted in aluminum & mild steel, it renders long life & covers.

Basically this is a tubular type heater with higher watt density. It is casted in aluminium alloy to suit required shape with fixing holes. It has terminals at opposite side of the heated surface

|

|

|

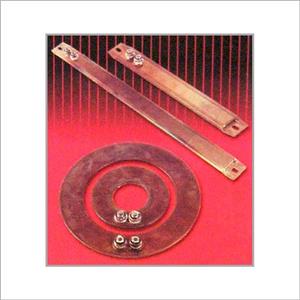

APPLICATION

HS / FS ring elements owing to their convenient shape & sizes, adapt themselves readily to variety of machines and appliances for which other type of heaters are not suitable. They are being fitted for heating platens, dies of presses. They are in use for melting of glue, wax, easily fusible metals

like leads, tin, solder, hot plates, popcorn machines, high speed packing machines, difussion pumps, kettles, large coffee percolators & wash boilers etc.

|

Quartz emitters provide medium wavelength radiation and can be the most preferred source of heat when rapid heater response is needed. The modules are comprised of a series of quartz tubes running parallel to each other within a highly reflective steel housing. Each tube contains a coiled resistance wire available in a variety of wattages and voltages. The large variety of sizes, shapes, and watt densities allows quartz emitters to be highly useful in zoning arrangements such as plastic thermoforming sheet-fed applications where complex heating patterns are needed, high-speed roll-fed processes, and machines requiring precise zone control because they are small in size, and can easily be put in larger panels.

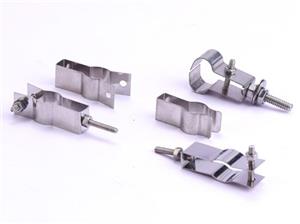

Description / Specification of Mounting Clips For Heater

We are involved in offering a wide range of Mounting Clips For Heater to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Mounting Clips For Heater. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

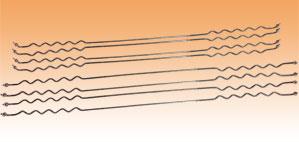

Microtubular coiled heaters are manufactured to a revolutionary design, which makes them the best choice in the most demanding conditions. The resistive wire is uniformly distributed in a compacted MgO insulation, with a CrNi-steel outer protection sheath. The heaters are annealed after manufacturing, thus acquiring a high malleability that allows their being subsequently bent into any complex shape, with extremely narrow bending radius. heaters are used in various applications, due to their being intrinsically reliable and highly versatile. They were first designed for a very specific application, the differential heating of plastic injection nozzles, and later become invaluable in the most diverse and demanding applications. Aerospace, railway, chemical, metalworking and food industry, glass and paper industry, automotive, packing, medical industry... all have taken advantage from the use of heaters, with their wide range of possible shapes and their fitness to an unlimited number of applications.

The quartz glass is very pure and provides good transmission and temperature resistance

The unique twin tube design offers high radiation power and very good mechanical stability allowing emitters of lengths up to 3.5 meters. Emitters are available in Short Wove, Medium Wave, or Long Wave versions. That gives you the possibili-ty to select the optimum wavelength for the material to bo hooted. Dimensions and filaments are matched to requirements.

Twin Tube Infrared Heater is made by virtue of a gold & white coated which con emit heat directly to the product. A coat-ing on the infrared emitters reflects the infrared radiation. Consequently the infrared radiation impinging on the product is virtually doubled.

Strip finned heaters consist of refractory insulated heating element, covered with zinc plated ms or ss sheet with fixing holes. Finned heaters are for more coverage of suface area. They are used where high velocity of air to be heated

These heaters are generally used where high temperature required in smaller space, as the same is having much watt density than strip heaters. This heater is also applied in air ducts, comfort heaters, load resistors, recirculating ovens etc

Wire would coil is inserted into metallic tube (M.S., S.S., Incolloy etc.) compactly insulated by magnesium oxidised fused powder. The terminals are brazed ruggedly. Rust resistant steel finns are mounted on the tube alongwith the holding clamps. Stainless steel or incolloy sheathed spirally would coil embedded in centre with Mgo. With M4 SS terminal studs. Finns are available either in zinc plated M.S. or S.S. Fully annealed heater is also available for bending / shaping as per requirement. It can be installed either with M.S. brackets, nipple assembly or ferrul type compression fit assembly, suitable to fit in existing duct as per requirement.

Description / Specification of Tubular Finns Heater

We are involved in offering a wide range of Tubular Finns Heater to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Tubular Finns Heater. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

APPLICATION

Description / Specification of Ceramic I.R. Heaters

We are involved in offering a wide range of Ceramic I.R. Heaters to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Ceramic I.R. Heaters. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

|

|

|

|

|

APPLICATION

Laboratory purpose, annealing, hardening of small components, research & developments etc. suitable up to 900 Deg. C.

CONSTRUCTION

Refractory Muffle with electric resistant wire wound on outer surface & insulated with cerwool. It will be housed in thick guage MS cabinet with single door. Temperature can be controlled with either Energy Regulator OR Digital Temperature Controller.

APPLICATION

For melting solder, dipping parts, poring in moulds, mfg. of PCB, soldering of electric terminals etc.

CONSTRUCTION

Stainless Steel Pot fitted with electric heating element with temperature controller, housed in MS enclosure. Fabricated as per specific requirements.

APPLICATION

Heating tools & cutting knives for dressing rubber articles & various other applications where hot tool is required.

CONSTRUCTION

Aluminum or MS heating chamber fitted with electric heater on outer surface. Housed in insulated MS powder coated casing. Fabricated as per requirement.