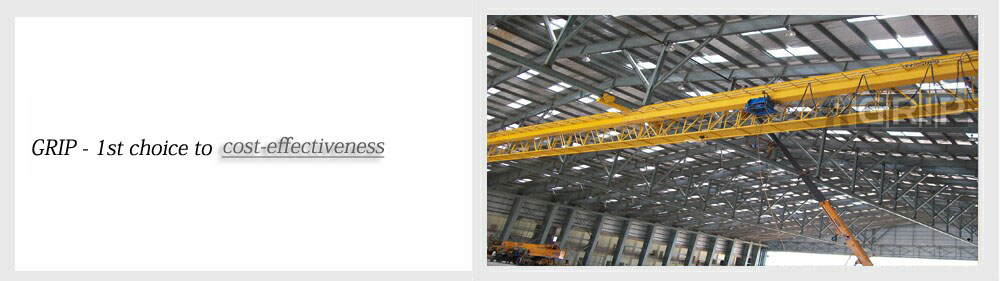

Eot Cranes

'GRIP' cranes are individually designed to suit customer specifications. All the relevant details are studied exhaustively before designing the cranes. Proper stress analyses are made for optimum design ensuring minimum crane structural weight, wheel loads Headroom and clearances thus reducing the building cost. Most modern computer aided designing (CAD) ensures availability of design information faster. "GRIP" cranes are available upto 200.0 tons.