GRANULES INDIA LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to GRANULES INDIA LTD.

Active Pharmaceutical Ingredients

At Granules, we focus on efficiently creating high-quality APIs in key therapeutic categories with dedicated installed capacity of 26,360 TPA in the Core business, 283 KL in the Emerging business and 152KL in the current CRAMS business.

We are one of the global leaders in Ibuprofen, Paracetamol, Metformin, Guaifenesin and Methocarbamol. Our focused API portfolio has made it possible for us to emerge as one of the most efficient and cost-effective manufacturers, globally. We serve the needs of our customers through four API facilities and one intermediate facility in Hyderabad and Vizag.

Through the acquisition of Auctus Pharma in 2014, 12 APIs have been added to our portfolio across several therapeutic categories.

In addition to efficiently streamlining the manufacturing processes for the existing list of products, our R&D team has developed and commercialized several products. Such product categories include anti- retrovirals, anti- hypertensives, anti-histamines, anti- infectives, analgesics, anti-coagulants, anti-fibriotics and platelet inhibitors.

Research and development of APIs is based on advanced technology, intellectual property, expertise and knowledge of regulations. Product development is geared towards quality, safety and efficacy of drugs and cost efficiencies for our customers.

Pharmaceutical Formulation Intermediates

Granules pioneered the concept of commercializing PFIs or Pre formulation Ingredients, a conception for large-volume drug molecules within the pharmaceutical production.

We entered into this business segment in the early 90s, following an insight that most finished dosage manufacturers were not efficiently producing PFIs. Manufacturers were granulating but could not derive operational efficiencies. They focused on dozens of products or only created large-volume products in limited quantities, each batch of which was processed & tested individually.

Consequently, it increased the overall cost to the manufacturers and in turn the customers, which finally resulted in an increased cost of product to the end consumer. This also pulled down the overall return from the manufacturers’ ‘investments,’ especially because PFI manufacturing accounts for 80% of the total cost of a finished dosage.

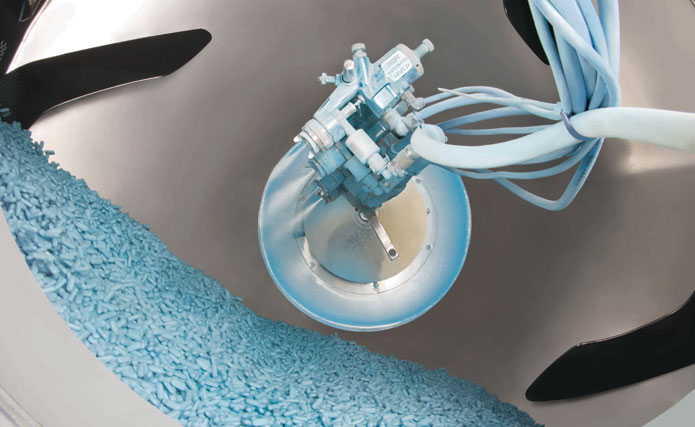

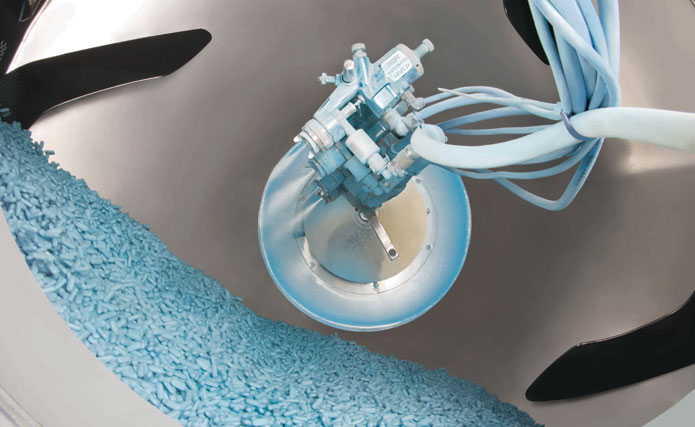

Granules India offers PFIs that are meant to be taken from ‘drum to hopper’

by our customers. The pre-formulation ingredients are taken directly from the drums to a hopper, where they are directly compressed into tablets.

Finished Dosages

Granules India offers multiple finished dosage forms, comprising tablets, caplets and press-fit capsules in bulk, blister packs and bottles.

We provide unique rapid release tablets, bilayer tablets and extended release (ER) tablets, strengthening the competitive advantage of customers. We have our own ANDAs and dossiers, which enable customers to enter related markets easily.

We also have a dedicated team for site-transfer related projects. We are the only Indian pharmaceutical player to manufacture ‘pressfit’ (rapid release tablets) dosages and are among the few to manufacture bi-layered tablets.

At GPI, our objective is to focus on formulation R&D and low volume manufacturing by leveraging a niche technology that enables us to make dosage forms with specific release capabilities like pulsatile drug release in tablet and capsule dosage form , orally disintegrating modified release tablets (XR, MR, ER), modified release suspension and controlled substances capabilities in an abuse deterrent technology platform .

Api

Description / Specification of Api

We are involved in offering a wide range of Api to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Api. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Oncology

Speciality Products: Oncology, High Potent APIs & Finished Dosage Forms

A key step to progress our growth strategy within the Emerging business, initiated in 2014 was Granules’ venture into the development of APIs forward integrated into finished dosages within the Oncology therapeutic segment.

At the Granules Research Center, we develop the APIs within this segment along with other high potent APIs. Our R&D team possesses a unique expertise in physical properties and polymorphism screening, generation, characterisation and stabilisation. These APIs will be manufactured at a state of art manufacturing facility spread across 18 acres, currently under construction in Vizag.

Please find below, our Oncology portfolio. We are open to discussions regarding our offerings and are flexible to work with our customers based on their requirements, schedules and other chemistry related aspects. We can also offer samples for the products that are in the advanced stages of development with a lead time of 30 days upon confirmation

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.