Beverage Processing Plant

Ready to Serve / CSD Beverage Processing Plant – 100 LPH to 15000 LPH

For projects awarded on Turnkey basis, we are in the capacity to offer project for RTS Beverage Lines for fruits like Passion Fruit, Synthetic flavored drinks, Guava, Mango and so on from Planning – to – Visualization to Realization. We also manufacture process lines for RTS beverages & Carbonated soft drinks that consist of the following section:

Sugar Syrup Preparation Unit

Here Sugar syrup of 65-70 Brix is prepared by dissolving the sugar in heated water. After the preparation, Sugar Syrup is passed through a filter for purification and then temperature is decreased after which it is transferred into the Ready Sugar Syrup storage tank wherein the syrup is then routed to the blending tanks as and when required.

Pulp Unloading Section

Bag in Barrel/ Cans or Pulp processing unit are the three ways to get Pulp into the Ready to serve processing unit.

Beverage Blending Section

Here blending of the sugar syrup, pulp, R.O water and additives are mixed in proper proportion with constant stirring. This is the initial mixing process to avoid separation between these product (sedimentation) we need to homogenize for complete blending/mixing the mix and stored in homogenized juice storage tank.

Sterilization Section

Before filling the product external biological agents/bacteria/fungi should be eliminated which may have entered or being present in product in the process will be eliminated by pasteurizing/sterilizing though plate/tubular/spiral flow/scrapped surface type heat exchangers which heat ups the product to 90deg C. and then sent it to the filling section.

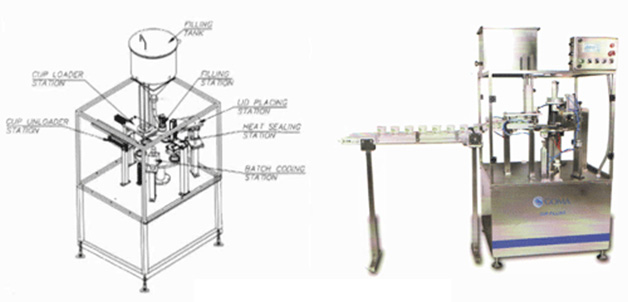

Filling section

We can fill the product in pet bottles/brick pack/ HDPE bottles Depending on type of filling the outlet temperature has to be set.

Carbonated Soft Drink Blending Section

In this section the concentrate will be blended by addition of RO water, sugar syrup, flavours, additives etc. The concentrate blend will be stirred. From CSD blending tank, the product will be passed thought mixomatic which can be connected to the PET bottle filling machine.

Clean–In–Place System

Necessary CIP system automatic / Semi Automatic / manual (Trolley Based) is provided to clean the equipment’s after the completion of the process. The CIP system consists of acid, caustic, hot water tanks, transfer pumps, PHE/THE for maintaining required temperatures and interconnecting pipes and fittings. The cycle of the CIP system is arranged as per the process requirement & production schedule.