GLOW PLAST MACHINES PVT. LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to GLOW PLAST MACHINES PVT. LTD.

Injection Moulded Scrap Grinders

Low Noise Enclosure Option is available for the above models.

Suitable for grinding of all Thermoplastics, which includes Nylon, Delrin, San, Polycarbonate, ABS, Glass Filled etc.

Energy Saving

Scissor Cutting Action

Low Noise Option Available

Double Jacketed Hopper

D3 Blades

Can cut the toughest materials with ease

Safety Interlocking System

Blow Moulded Scrap Grinders

|

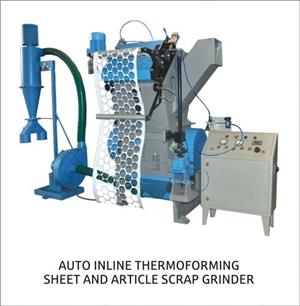

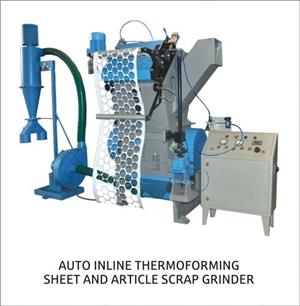

Thermoforming Sheet Scrap Grinders

Our motto – Minimize Wastage and Maximize Profits. All our machines are well known for their Ruggedness, Reliability and Low Power Consumption.

Low Noise Enclosure Option is available for the above models.

Suitable for grinding of HIPS, PVC, PP, PET, Thermoforming sheet scrap and articles. Auto Feed Inline Series :

Auto Feeding

Completely Inline

No operator required

Sound Proof Enclosure

Fitted with AC Drive

Optional Edge Trim Grinder

Blower Discharge for Closed Loop Recycling

Pet Bottles Preforms Grinders

Our motto – Minimize Wastage and Maximize Profits. All our machines are well known for their Ruggedness, Reliability and Low Power Consumption.

Low Noise Enclosure Option is available for the above models.

Suitable for grinding of PET Bottles, Jars and Preforms.

High Output

Low energy Consumption

Scissor Cutting Action

Built in Water Cooling System

Minimum Dust Formation

Low Noise Option Available

Pipes Profiles Scrap Grinders

Our motto – Minimize Wastage and Maximize Profits. All our machines are well known for their Ruggedness, Reliability and Low Power Consumption.

Low Noise Enclosure Option is available for the above models.

Suitable for grinding Pipe scrap of PVC, HDPE, Profiles and also pipe fittings. Side chute is provided for direct feeding of long scrap pipes / profiles.

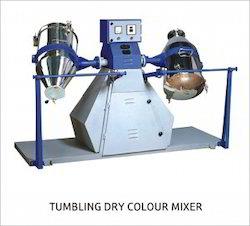

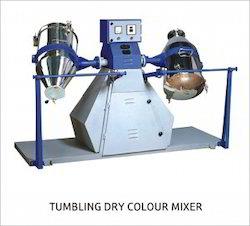

Tumbling Type Plastic Dry Colour Mixers

Our motto – Minimize Wastage and Maximize Profits. All our machines are well known for their Ruggedness, Reliability and Low Power Consumption.

Suitable for mixing of granules with Pigments Masterbatches, Liquids Masterbatches. Also used for homogeneous mixing of grinding and virgin materials.

The vessels are made from Heavy guage of S. S. 304 Sheet.

Vessels are also fitted at an angle for better and faster mixing

Geared motor drive for lesser power consumption.

Protective Guard with Safety Interlock

Offers consistent material mixing

Standard models available from 25 kg/batch upto 200 Kgs/batch

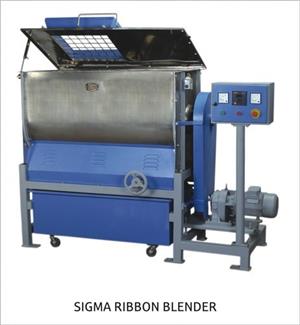

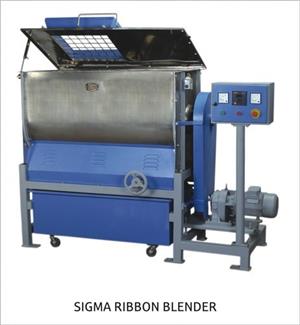

Sigma Ribbon Blenders

Our motto – Minimize Wastage and Maximize Profits. All our machines are well known for their Ruggedness, Reliability and Low Power Consumption.

The above model can be integrated with a Mechanical Hopper Loader system.

The best solution for mixing medium sized batches of raw material, regrind and masterbatch. These Blenders can be integrated with a mechanical hopper loader for an automated solution.

FEATURES :

Rugged Construction

Suitable for large volumes

Homogeneous mixing

Tailor made to your mixing requirements

Designed for fast mixing

Lower power consumption

Integration possible for automated solution

Plastic High Speed Mixers

Our motto – Minimize Wastage and Maximize Profits. All our machines are well known for their Ruggedness, Reliability and Low Power Consumption.

Suitable for preheating plastic materials, for removing moisture and PVC Compounding.

Features :

M. S. Vessel / S. S. Vessel

Suitable for Pre-heating

Moisture Removal

PVC Compounding

Plastic Universal Vertical Quick Mixer

Our motto – Minimize Wastage and Maximize Profits. All our machines are well known for their Ruggedness, Reliability and Low Power Consumption.

The best solution for large batch mixing of raw material, regrind and masterbatch. These Blenders can be integrated with a mechanical hopper loader for an automated solution.

FEATURES :

Rugged Construction

Suitable for large volumes

Homogeneous mixing

Tailor made to your mixing requirements

Designed for fast mixing

Lower power consumption

Occupies a smaller area

Integration possible for automated solution

Dust Separator

We are proud to be the first in India to introduce a range of Dust Separating Systems. These can be retrofitted on your existing grinders or can it fitted on your new grinder.

Why Separate?

Fines and Dust generated during the grinding process can cause contamination in your processing equipments.

Dust causes Black Spots on your moulded product and leads to a lower product quality.

Dust can prove a health hazard.

Principle:

Separation is a simple process. The grinding material is passed through a blower cyclone at high pressure. The pressurized air lifts the lighter dust and fine particles and pushes them out through a separate outlet, leaving the cleaner dust free grinding material to fall through the main outlet.

You can even opt for a single central dust separating system to handle all your moulding and grinding machines.

Blade Resharpening Machine

Suitable for re-sharpening blades of Grinders, Agglomerators and Pellitizers. These economical machines increase the life of your blades and give you control over the knife sharpening process. No need to send blades outside for re-sharpening when you can do them in house. The machines are compact, portable and robustly built.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.