FLUIDYNE INSTRUMENTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FLUIDYNE INSTRUMENTS P.LTD.

Flow Switches

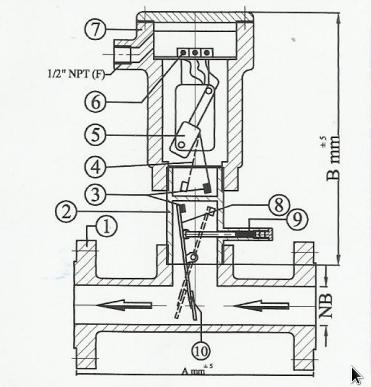

FLUIDYNE MAGNETIC & BELLOWS SEALED flow switches are versatile instruments designed to handle any fluid. Standard materials of construction and glandless design offered render the switches compatible with most of the corrosive and toxic fluids. The easy-to-fix design reduces installation costs and time. Simple mechanical parts ensures high reliability and zero - failures. The microswitch of the instrument is operated by the deflection of paddle or plunge assembly due to velocity of flowing-fluid against the restraining force of the range spring through a magnetic scaled lever at a predetermined flow rate.

FLUIDYNE switch also senses flow - no flow, responding only to the velocity of fluid movement in a duct.They provide a positive signal to detect change or loss of flow velocity caused by closed damper, a loose fan wheel, a slipped or broken fan belt, a dirty or clogged filter or even an overload to fan motor. Large paddle are used for reliable velocity switching.

GENERAL SPECIFICATION:

Line size: 15mm to 1000mm (N.B.).

Mounting: vertical or horizontal pipe.

Range: refer table for standard range.

Repeatability / Accuracy: +1-5% of Maximum flow.

Process Connection: BSP/NPT for threaded versions,

(1" or 1.1/4" NB) ANSI # RF for flanged versions,

1/2" to 12" pipe threads for integral,

tee versions, special Sizes as per customer request.

Maximum Line Pressure: 10 bar for brass body.

30 bar for SS BODY ( higher rating available on request upto 300 bar

1 bar for duct mount version.

Maximum Process Temperature: 170 Deg.0 for brass body.

200 Deg.0 for SS body.

Pressure Loss: 60 to 80 m bar at maximum flow.

Mounting: vertical or horizontal pipe.

Switching: snap acting SPCO, (SPDT), DPDT

microswitch rated 5A, 230V AC or 10A, 230V AC.

Dead Band: 5 to 10% of maximum flow ( 10% at min. set valve

& 5% at max set valve ).

Enclosures: pressure die cast aluminium weather proof to I.P. :65 &

flame proof to Gr. 11 A & 118 of IS : 2148: 1981, on request.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.