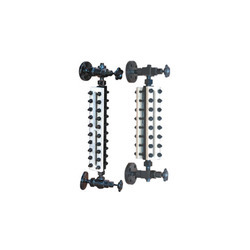

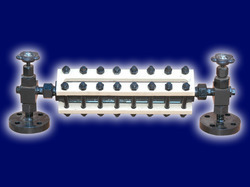

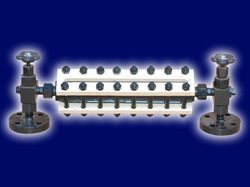

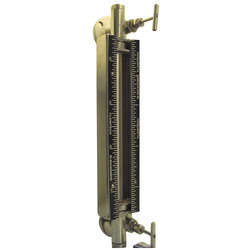

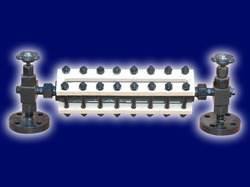

Reflex Transparent Level Gauges

Product Details:

Minimum Order Quantity 1 Piece

Brand FLOWTECH

Model RTLG-0159

We are a known name in the market owing to the success of Reflex Transparent Level Gauge. This product from our side is particularly using for high pressure or high temperature or toxic liquid storage tanks. These gauges have a prism glass window that uses the basic optical principles of light refraction & reflection to enhance the indication of the liquid level and are made available at market leading rates.

Features:

Prism glass window

High temperature range

Varied pressure range

Applications:

Scientific laboratory

Research centres

Chemical industries

Specifications:

Type: Reflex / Transparent

Visibility: Full Visibility / Partial Visibility

Liquid Chamber: Carbon Steel, S.S.304, S.S.304 (L), S.S.316, S.S.316 (L), P.P

Type : Reflex / Transparent

Visibility : Full Visibility / Partial Visibility

Liquid Chamber : Carbon Steel , S.S.304, S.S.304 (L) , S.S.316 ,S.S.316 (L), P.P

Cover Plate : Carbon Steel , S.S.304, S.S.304 (L) , S.S.316 ,S.S.316 (L), P.P

Gasket : CAF , PTFE , Graphoil , Other On request

Glass : Borosilicate Toughened of Indigenous – Temperature Range upto 125oC , Klinger / Maxos Make

Temperature Range Upto 400oC , Other on request

54635.jpg)