FLOWTECH MEASURING INSTRUMENTS P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FLOWTECH MEASURING INSTRUMENTS P LTD.

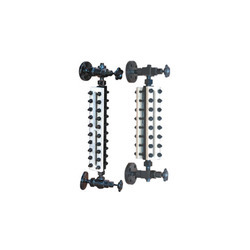

Conductivity Points Level Switches

FLOWTECH Conductivity Type Level Switches are intended for level detection of Tank Level Control and Pump & Process Protection in Electrically Conductive Liquids such as Water, Beverages, Lye Solutions, Acids, and Graphite etc. These are available in Top Mounting OR External Cage Top Mounting versions. These are Cost effective & having Reliable Performance, Easy installation, Ideal for simple applications, No moving parts hence long term reliability.

WORKING PRINCIPLE

Conductive Electrodes detects the level when the Electrodes are coming into contact with the Liquid. A low adjustable resistance, alternative current flows between the grounds (Earth) and the Electrode. This current is detected by signal conditioning instrument and processed into a switching signal. The switch point is determined by the length and mounting position of the appropriate electrode. In conductive Tank / Vessels, the Tank / Vessel wall forms the ground electrode and incase of a plastic OR FRP OR Rubber Lined (NON CONDUCTIVE) Tank / Vessel, the conductive electrode consists of one of the probes.

DESIGN FEATURE :

Process Connection : Minimum 1½” ANSI 150 # RF (FLANGED) OR SCREWED OR as per requirement.

Input Power : 0.5 Amp @ 240 V AC OR 415 V AC OR 24 V DC

Switch Housing : Die Cast Aluminium, Weather Proof IP 65 (Enclosure)

Operating Pressure : Upto 30 Kg/Cm²

Operating Temp : Maximum 1300 C.

No of Rods : Maximum 5 Rods.

Length of Rods : As per requirement.

MATERIALS OF CONSTRUCTION :

Electrode Tip : SS316 / MONEL / Hastalloy ‘C’.

Electrode Sleeve : SS Sleeved with PP / PTFE.

Flanges : CS / SS304 / SS 316 / PP / PVC / HDPE / MS with PTFE OR Rubber Lined.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.