FITWELL ENGINEERING COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FITWELL ENGINEERING COMPANY

Gelatin Filter Press

Edible products like alcoholic beverages and oils, edible gelatine have to be filtered clear of all the superfine particles which get entrained during processing of the product. Our polishing press offers a large flow rate, a stable and reusable filtering medium and ensures filtrations to remove suspended particles of less than 1 micron size. At a first glance it appears like a conventional filter press. In actuality, it is a set of chambers having wide openings against which specially made filter pads fit snugly. It has only one and two button type filter elements. The filter media is paper pulp pad, woven fabric can also be used.

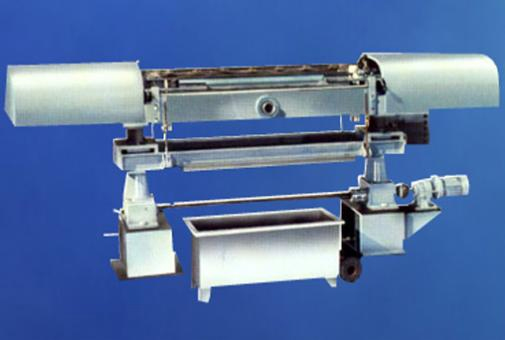

Pulp Pad Cake Press

Fibrous filter media like cellulose is used in Filter Presses. This media is free from binders and hence must be compressed to form a stable padding. At the same time, high volume of filtering media must also be discharged very quickly.In initial stage, the press is closed while the punch is in lifted position. Very dilute suspension of fibrous material is admitted on centeringchamber in requisite amount. Due to filter wire mesh and quick draining surface below the chamber water starts draining off. After sufficient suspension is poured the top punch is lowered by hydraulic mechanism. By the pressure of the punch more and more water is flushed out. In a short while all water gets drained and pulp forms into a stable pad. Now punch is released and whole pad is swivelled. The guiding ring for pulp pad is removed and the pad can now be ejected from its place for drying and stored for future use.

SPECIAL FEATURES:

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.