FISCHER MEASUREMENT TECHNOLOGIES INDIA P.LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FISCHER MEASUREMENT TECHNOLOGIES INDIA P.LTD

Gold Testing Machines For Hallmarking Centres

GOLD TESTING MACHINES FOR HALLMARKING CENTRES

Gold Testing Machines For Jewellery Retail Stores

Buying and selling gold has become an established market. Since dealers typically have only a few minutes to determine the value of the item offered for sale, unreliable methods such as the touchstone are frequently used. More accurate but also destructive is the time consuming fire assay, X-Ray fluorescence, on the other hand, offers a non destructive , quick and very reliable method for material analysis and coating thickness measurement on jewellery, watches & other precious metal items.

Gold Testing Machine For Assaying Refinery And Tunch

Karat Meter Gold Testing Machines are one of the vital tools in the domain of jewelry, banking, mining, precious metal, materials researching laboratory, etc. The range is designed precisely using advanced technology spares and parts to accurate analysis of gold and other precious metals. We have been offering matchless product line focused on boosting the weighting resolution, making the procession of weighing easy and detecting the prohibited substances. The array of Gold Karat Meter Testing Machine, offered by us, is designed with advanced software application and function to ensure the reliability of measuring results. The collection is available in different models and specifications as per the exact needs of the clients with striking features of accurate results, low maintenance and power saving designs.

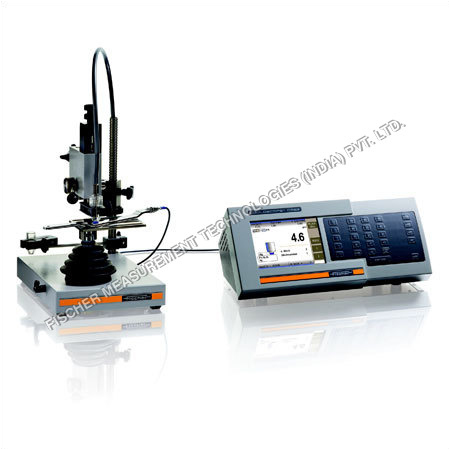

Benchtop Unit Mms Pc

The stationary multi-measurement system with built-in Windows⢠CE and network capability is ideally suited for non-destructive, high-precision coating thickness measurements and material testing. The MMS PC2 can be operated using either the large, high-resolution colour touchscreen or a keyboard and mouse. It features LAN and USB ports for integration into automated production processes. In addition, it can operate up to eight probes in parallel.

Pocket Gauges

"Fischer Coating Thickness Meter: A compact devices of the MP0 and MP0R series are an economical solution for quick and easy coating thickness measurements in the corrosion protection field. When it comes to examining the layers that protect ships, bridges or other hard-to access steel structures, these lightweight and hand sized instruments really show their strength. "

Probes For Coating Thickness

High resolution probes execute the conversion of coating thickness into an electrical signal which is in order to unveil the value of coating thickness on the display screen of device. Our high resolution probes have special cavity probe V3FGA06H designed for non-destructive measurements of EPD coatings ensuring high efficiency. These have patented conductivity compensation that enables adjustment for various base material conductivities. High resolution probes have spring-loaded system that ensures the decrement in calculation errors and thus helps in increasing the accuracy of the device.

Handheld Gauges

Due to their interchangeable probes, the handheld instruments of the FMP family are well suited for performing non-destructive coating thickness measurements through magnetic induction (DELTASCOPE), eddy current (ISOSCOPE) or both (DUALSCOPE). The instrumentsâ modular design allows individual assembly of the appropriate measurement system for the respective measuring task. Besides differently equipped instruments, numerous high-precision probes are also available.

Wafer Coatings

WAFER COATINGS

Specific X-ray Fluorescence Measuring Instruments (XRF) for Measurements and Analyses of Coating Thicknesses and Compositions on Wafers

The instruments are particularly suitable for measurements on structures on wafers in the electronics and semiconductor industries, Analysis of very thin coatings, e.g., gold/palladium coatings of ⤠0.1 μm (0.004 mils) & Determination of complex multi-coating systems Automated measurements, e.g., in quality control

Coating Thickness Measurement On Connectors

Description / Specification of Coating Thickness Measurement On Connectors

We are involved in offering a wide range of Coating Thickness Measurement On Connectors to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Coating Thickness Measurement On Connectors. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Pvd And Cvd Coating

Description / Specification of Pvd And Cvd Coating

We are involved in offering a wide range of Pvd And Cvd Coating to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Pvd And Cvd Coating. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Bath Analysis

We are engaged in offering a wide range of bath analysis. These are engineered in accordance with international industrial standard and using best available techniques. These are available with us in various range including plating bath analysis instrument â XUL, bath analysis coating thickness â XDL, bath analysis coating thickness - XAN 250, bath analysis coating thickness - XDV-SDD and bath analysis coating thickness â XDLM.

Wafer And Lead Frame

High Repeatability Precision and Trueness of Au / Pd Coating Measurements on Leadframes along with Specific X-ray Fluorescence Measuring Instruments (XRF) for Measurements and Analyses of Coating Thicknesses and Compositions on Wafers for Measurements on structures on wafers in the electronics and semiconductor industries

Wires

Description / Specification of Wires

We are involved in offering a wide range of Wires to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Wires. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Analysis Of Thin Film Solar Cells

Production quality of thin film solar cells can be accurately and precisely monitored using the X-Ray Fluorescence (XRF) methodology. Specifically tailored inline measurement instruments are available that fulfil the robustness requirements in production environment. Clever software features enable simple setup and handling of the measurement instruments whilst ensuring stable measurement and maintaining comparability between them.

Electroplating And Electroless Coatings

The combination of state-of-the-art detector technology such as SDD, multiple excitations in various modes, and the powerful analysis software, WinFTM® , allows for reliable, accurate measurements of both coating thickness of electroplated materials and phosphorous content of electroless nickel coatings on a wide variety of substrate materials. The XRF machine unites all these performance features in one instrument.

Coating Thickness Measurement On Watches

Watch hands, faces, gear wheels and other visible elements inside high quality watches are often plated with gold or other precious metals that lend the watch its elegant look. Here, not only is the visual effect important but also the precise functioning of the parts. Tight tolerance limits require extremely precise coating thickness measurements, such as those achieved using X-ray fluorescence

Solder Joints

Solder joints are engineered using best available techniques and following international industrial standard. These are extensively recommended by clients owing to its precise design and effective usage. These are available in various range including solder joints coating thickness measurement - XDLM 237, solder joints coating thickness measurement - XDV-SDD and solder joints coating thickness measurement - XDV-u

Pcb

Specific X-ray Fluorescence Measuring Instruments (XRF) for Measurements and Analyses of Coating Thicknesses and Compositions on Printed Circuit Boards. Also determination of copper coating thickness on non-etched or etched PC boards and determination of copper coating thickness in bore holes using handheld instruments.

Pcb Coating Thickness Measurement

The SR-SCOPE® RMP30-S measures the thickness of copper coatings on the top side of pc-boards according to EN 14571. It is particularly well suited for measurements on multilayers or on thin laminates due to the measurement method, copper layers that are located opposite of one another do not influence each other.

Destructive Coating Thickness Measurement

This benchtop coating thickness measurement unit â Couloscope CMS2 is used to measure metallic coating over the metallic and non metallic substrate. It can measure both single layer and multi-layer coating. It is provided with graphical display for having a clear view of measurement. It has various predefined measurement applications for various types of metal coatings. Our benchtop coating thickness measurement unit â couloscope CMS2 has selectable measurement units and has various display languages options such as Asian, South American and European.

Couloscope Cms Step

The CMS2 STEP features the additional STEP Test (Simultaneous Thickness and Electrochemical Potential determination) function. It is used for standardised STEP Test measurements of individual coating thicknesses and differences in potential (according to ASTM B764-94 and DIN 50022) in the quality control of multiplex nickel coating systems.

Micro Hardness Testing

All FISCHER instruments employ Instrumented Indentation Test method â often called nanoindentation â for determining the Martens Hardness (HM). In contrast to other hardness tests, this method not only determines the plastic behaviour of the material, but additional material parameters can also be read from the measurement plot, such as the Elastic Modulus of Indentation (EIT), the Indentation Hardness (HIT) and the Indentation Creep (CIT), as well as the plastic and elastic deformation energies

Sealing Quality Testing

Our sealing quality test â anotest is weather resistant and designed in compliance with the DIN EN ISO 12373-5 and ASTM B 457-67 standards. It is basically a sealing quality tester of anodic coatings on aluminum. It is equipped with LCD display which shows the readings accurately in no time. This sealing quality test â anotest is designed with utmost precision by our professionals using superb quality material and advance machines.

Ferrite Content Measurement

Feritscope FMP30 is extensively used in different industries to measure ferrite content in steel. It helps in maintaining the grades steel as excess or deficit of ferrite can lead the adverse impact on the quality of steel. If the ferrite content in steel is too high, the ductility and toughness as well as corrosion resistance of the steel is undermined and if it lacks then it will result in hot-cracking of weldment. Thus the test of ferrite content is necessary because the structures made of steel are generally exposed to aggressive media, high pressure and heat in process engineering, power and chemical plants.

Electrical Conductivity Measurement

Our electrical conductivity measurement instrument - sigmascope SMP350 is designed with utmost precision to measure the electrical conductivity of metallic conductor accurately and precisely. Our sigmascope SMP350 is also used for assessing hardness and strength of various heat treated materials. Electrical conductivity is a basic material property which gives information about metal's ability for conducting electrical current.

Porosity Testing Instrument

Our porosity testing instrument HV20 found various applications in paint and engineering industries for finding porosity and cracks in the coating which can harm the material on which coating is done. This porosity testing instrument HV20 is available in different specifications and models. It is generally used on agitator kettles, mineral oil tanks, boilers, pipelines and heat exchangers. Furthermore, it is also demanded for food packages which are plastic coated.

X Ray Fluorescence Instruments

Whether for high-precision coating thickness measurements or exact material analysis, the broad assortment of FISCHER X-ray fluorescence measurement systems has the optimal instrument for any application. In addition to many innovations and patents, the FISCHERSCOPE X-RAY product line integrates more than 30 years of experience and continued development.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.