UNITECH ENGINEERING COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to UNITECH ENGINEERING COMPANY

Automatic Filling Machine

A superiorly efficient range of Automatic Filling Machine exists with us. We are an exuberant manufacturer of high quality automatic filling machine. Minimum surveillance is required for our automatic filling machine. These robust automatic filling machines are obtainable from us on rock bottom rates.

Plc Based Filling System.

having Digital Volume and Weight

display. Therefore Quick Change

over for Different Volume.

Bench Model (Semi Automatic Filling Machine)

39422.jpg)

Our Semi Automatic Filling Machines (Bench) are diligently designed as per the demands of the clients. These Semi Automatic Filling Machines (Bench) are highly reliable and durable and thus hugely demanded by clients in the global markets.

Specifications

Mechanical no electricity required

Filling range 250 liters to 5 liters

Attachment for 100ml filling available

Also available from 3 liters to 50 liters

Output 8 to 10 cans bottles per minut

adjustable platform as per size of container.

adhesive

Semi Automatic Filling Machine Floor Model

Our Semi Automatic Filling Machines (Floor) are diligently designed as per the demands of the clients. These Semi Automatic Filling Machines (Floor) are highly reliable and durable and thus hugely demanded by clients in the global markets.

Specifications

Mechanical no electricity required

Filling range 2 liters to 25 liters

Also available from 3 liters to 50 liters

Output 3 to 4 cans per minute fro 15 liters

Adjustable platform as per size of container.

Product can be filled:

Oil

Paint

Varnish

Thinner

Ink

Milk

Chemicals

Lubricants

Adhesive

Loadcell Based System Filling Machine

Loadcell Based System Filling Machine

Our Semi Automatic Filling Machines (System) are diligently designed as per the demands of the clients. These Semi Automatic Filling Machines (System) are highly reliable and durable and thus hugely demanded by clients in the global markets.

Specifications

Mechanical no electricity required

Microprocessor based system.

Filling Range 200mI to 20 Itrs.

Pneumatically operated system

Diffarant capacity available

Two stage fillage system.

All content part in stainless steels 304/ 316 quality.

Having Auto/Manual, Gross /Net Mode.

Intellegent correction for high accuracy.

No Jar no fill systems in auto mode.

Product can be filled:

Oil

Paint

Varnish

Thinner

Ink

Milk

Chemicals

Lubricants

Adhesive

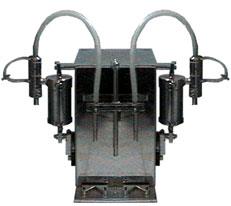

Two Head Piston Filling Machine

Two Head Piston Filling Machine

Our Two Head Piston Filling Machine are diligently designed as per the demands of the clients. These Two Head Piston Filling Machine are highly reliable and durable and thus hugely demanded by clients in the global markets.

Specifications

Motorised or pneumatically operated.

Filling range available from 5ml to 5ltrs in different machine.

In pneumatic model complete microprocessor based system.

ALL Contact pats in stainless steel 304/316 qualityy

Product can be filled:

Oil

Paint

Varnish

Thinner

Ink

Milk

Chemicals

Lubricants

Adhesive

Semi Automatic Filling Machines With Bench Model

Description / Specification of Semi Automatic Filling Machines With Bench Model

We are involved in offering a wide range of Semi Automatic Filling Machines With Bench Model to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Semi Automatic Filling Machines With Bench Model. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Automatic Volumetric Filling Machine

Filling Range 250ml TO 5 Ltrs. & 5 Ltrs. To 20 Ltrs..

- Drip free nozzles with filling range of 250ml to 5000ml/5Ltrs. to 20 Ltrs. with drip tray for accidental drip.

- Non contact electronic sensor to ensure "no bottle no fill" system.

- Available from 4 head to 16 head.

- Mitsubishi make PLC system with 7" Touch screen and VFD control for conveyor speed control.

- German flow meter for better repeatability of 0.05%. Having in built non liquid contact sensor for measuring rotation of chamber. All contact parts in Mild steel / Stainless steel plating.

- Body frame made up of M.S. with Powder coating or Stainless steel. All contact parts stainless steel.

- Capable of automatic intake of empty bottles / container on to the filling station and discharge after filling bottles with the help of stop and release lever pneumatically operated.

- Fast flow and fine flow system for better accuracy, Interval can be set form PLC, Volume would be set individually for each nozzle with increment of 1ml.

- Neck entry system so that the nozzle enter inside the container before filling to avoid spillage.

- Conveyor with stainless steel slats and suitable for filling 250ml to 5 Ltrs./5Ltrs. to 20 Ltrs. container along with electric motor for main drive and conveyor reduction gear box with variable frequency drive.

- Enclosed body with transparent Acrylic doors front and back.

- Pneumatically operated Nozzle Up-Down movement & stopper Gates for bottle entry and exit.

- Adjustment can be made without interrupting filling sequence.

- Manual valve on bypass line of pump.

- Pump of 200 Lpm.

- In built memory to store 25 Recipes.

- Filling accuracy of +/- 0.25% till 5 Ltrs. & 0.1% till 15 Ltrs.

- As flushing system is given the product change over time is 15 to 20 minutes.

Auger Filler

MICROPROCESSOR BASED CONTROL.

AUTO / FOOT PEDAL START.

COUNTER BASED CONTROL / LOADCELL BASED ALSO AVAILABLE.

FILLING CAPACITY AVAILABLE UP TO 50 K.G.

ALL CONTACT PARTS IN STAINLESS STEEL 304/316 QUALITY.

FILLING SPEED 20-22 JARS PER MINUTE AS PER QUANTITY TO BE FILLED.

FLAME PROOF MODEL AVAILABLE.

POWER: 230 VOLTS/440 VOLTS, 50 Hz.

MATERIAL CAN BE FILLED: POWER, GRANULES, SEMI-LIQUID, GREASE, OR MATERIAL OF HIGH VISCOSITY.

Pouch Packing Machine

We own a distinguish position amongst leading manufacturers and exporters of Pouch Packing Machines. Trend of pouch packaging is increasing immensely. Thus we proffer a vast range of highly potent pouch packaging machines. Our pouch packing machines work very speedily.

Easy to Change Over for Different Pouches.

Photocell Controlled.

Contact Parts in Stainless Steel

3,4 Side or Centre Seal.

Different Capacity Available for Both Liquid and Solid Material.

Packing Material : all Heat Sealable Material.

Power : 1/4 Hp Motor to 1 Hp Motor, 220v S.p. 50 to 60 Hz.

Heater : 3 Side Sealing 150w X 2 Pcs ; 300w X 2 Pcs.

Heater : 4 Side Sealing : 300w X 4 Pcs.

Induction Sealing Machine

Unitech Engineering has carved a niche amongst the prestigious induction sealer manufacturers in the industry. Our continuous induction sealing machine is manufactured from the best quality raw material, which is sourced from renowned suppliers. Our induction sealing machine is widely used by many well known industries located in India and abroad. We provide induction sealing machine at the most reasonable rates.

Auger Filler Machines

We are an eminent Manufacturer and Supplier of Auger Filler Machine, which is specially designed with best technologies. Auger Filler Machine is a complete solution for packaging powders such as talcum, curry, spices etc. This machine can be availed in different power capacity and at market leading prices.

Attributes

Simple design

Easy operation

Dimensionally accurate

Longer working life

Low to maintain

Flame proof

Specifications

Microprocessor based control

Auto Foot pedal start

Counter based control/ Load cell based also available

Filling capacity available up to 50Kg

All contact parts in stainless steel 304/316 quality

Filling speed 20-22 jars per minute as per quantity to be filled

Power : 230 volts and 440 volts, 50 Hz.

Apt for filling

Powder

Granules

Semi-liquid

Grease

Labelling Machine

Labelling Machine offered by us, is fabricated from optimum quality stainless steel that ensures high durability. Labelling machines caters to the needs of various industries such as chemical, food products, paints, lubricant & pharmaceuticals. We are positioned at the apex for manufacturing and supplying of Labelling Machine across the globe.

Material of construction

Stainless steel

Features

Self adhesive

Longer working life

Reliable

Low maintenance cost

High performance

Technical Details

Single side

Double side

Round bottle

Applications

Microprocessor/ PLC based system.

Stepper motor/ Servo motor base system

Feather touch keypad control

Power : 23 volts single phase 50 HZ

Lid Placing Machine

Product Description

[Lid Placing Machine] We offer the high performing Lid Placing Machine, which is designed for placing lid on different products. Lid Placing Machine is widely accepted in the both domestic as well as foreign markets for its robust frame and high performance. We are counted as one of the leading Manufacturers and Exporters of Lid Placing Machine.

Advantages

Auto lid placement system

Simple in design

Simple in design

Highly accurate

Longer life

Specifications

Mitsubishi make plc system with 4** Touch Screen and VFD control for conveyor speed control

Contact parts in Stainless steel 304 quality or powder coated

Body frame made up of Stainless steel or M.S powder coated.

Pneumatic lid orientation system.

8 feet conveyor with B Inches stainless steel slate

Power 415 Volts 3 phase SD Hz.

Linear Capping Machine

Product Description

[Linear Capping Machine] We are a prominent Manufacturer and Exporter of Linear Capping Machine, which is in hugely demand among the clients across the globe due to its longer working life and high performance. Linear Capping Machine is manufactured using advanced technology and used for capping different kinds of bottles.

Salient Features

Linear chuck capper and Side roller capper system

Sturdy construction

Longer working life

High performance

Corrosion resistant

Specifications

Mitsubishi make plc system with 4" Touch Screen and VFD control for conveyor speed control

Contact parts in Stainless steel 304 quality

Body frame made up of Stainless steel or M.S powder coated

No change parts required for different bottle size

Motorized Bowl or Cap elevator for orientation of caps

8 feet conveyor with 6 Inches stainless steel slats

Pneumatically operated head diving system

In built memory to store 25 setting data

Power 415 Volts 3 Phase 5D Hz.

Available from 1 to 4 head

Automatic Screw Capping Machine

Description / Specification of Automatic Screw Capping Machine

We are involved in offering a wide range of Automatic Screw Capping Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Automatic Screw Capping Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Automatic Capping Machine

Description / Specification of Automatic Capping Machine

We are involved in offering a wide range of Automatic Capping Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Automatic Capping Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Automatic Linear Screw Capping Machine

Description / Specification of Automatic Linear Screw Capping Machine

We are involved in offering a wide range of Automatic Linear Screw Capping Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Automatic Linear Screw Capping Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Automatic Linear Capping Machine

Description / Specification

- Linear chuck capper and Side roller capper system

- Available from 1 to 8 head

- No bottle - No cap system

- Mitsubishi make PLC system with 4" Touch Screen and VFD control for conveyor speed control.

- Body frame made up of Stainless Steel or M.S Powder Coated

- No change parts required for different bottle size.

- Motorized Bowl or Cap Elevator for orientation of caps.

- 8 feet conveyor with 6 inches stainless steel slats.

- In built memory to store 25 setting data.

- Power 415 Volts 3 phase 50 Hz.

Linear Gross Or Net Weigh Filler

Description/ Specification of Linear Weigh Filler Machine

We presents our customers a top-of-the-line array of Linear Weigh Filler Machine. for filling Oil ( Edible / Lubricant )

- Weigh metric Series.

- Filling range : 1 to 5 kg and 5 to 30kg

- Versatile : Minimum Adjustment Required for setting different capacities.

- Nozzle Type : Positive cut-off.

- Accuracy of Filling : +/-0.1% for 5 kg to 30 kg and 1 kg to 5 kg will be 0.25% filled volume.

- Completely PLC based system.

- Auto calibration system.

- Enclose cabinet with acrylic doors.

- Having 500 liters tank.

- Having course & fine filling system.

- Volume setting : 10 Inches wide HMI Touch Screen Graphic Display.

- No container No Fill.

- Filling modes : Net / Gross.

- Drip arresting tray below nozzle for accidental drip.

- Models : available in 4, 6, 8 and 12 head configuration.

Automatic Lid Placing And Pressing Machine

Description / Specification

- Auto lid placement system.

- No jar - No cap system.

- Mitsubishi make PLC system with 4" Touch Screen and VFD control for conveyor speed control.

- Contact parts in Stainless steel 304 quality or powder coated.

- Body frame made up of Stainless steel or M.S powder coated.

- Pneumatic lid orientation system.

- 8 feet conveyor with 6 inches stainless steel slate.

- Power 415 Volts 3 phase 50 Hz.

Servo Piston Filling Machine

Our Servo Piston Filling Machines are efficiently designed by the experts to provide a helping hand in the various hardcore industrial applications. These are renowned for giving hassle free operation in the small frame of time.

Specifications

Drip free nozzles with filling range of 100ml to 1000 ml to 500 ml to 5000ml (Different capacity available)

Available from 4 head to 10 head

Mitsubishi make plc system with 4" Touch Screen and VFD control for conveyor speed control.

Contact parts in Stainless steel 304 quality

Body frame made up of Stainless steel

Capable of automatic intake of empty bottles in container on to the filling station and discharge after filling bottles with the help of stop and release lever pneumatically operated

Neck Entry Nozzle system so that the nozzle enter inside the container before filling to avoid spillage

12 feet conveyor with 4 Inches stainless steel slats

Container along with electric motor for main drive and conveyor reduction gear box and variable frequency drive

Mechanically operated Nozzle Up-Down movement & Pneumatically stopper gates for bottle entry and exit.

In built memory to store 25 filling slate

Filling accuracy of el- 0.25%

Power 415 Volts 3 phase 5EI Hz.

Pneumatic Piston Filling Machines

Pneumatic Piston Filling Machines, offered by us, are hugely popular in the global markets for giving clients’ desired performance. Their robust construction and efficiency-raising features have raised their demand sky-high.

Specifications

Drip free nozzles with filling range of 400ml to 1000ml ( Different capacity available )

Available from 4 head to 10 head

Mitsubishi make plc system with 4" Touch Screen and VFD control for conveyor speed control.

Contact parts in Stainless steel 304 quality

Body frame made up of Stainless steel

Capable of automatic intake of empty bottles in container on to the filling station and discharge after filling bottles with the help of stop and release lever pneumatically operated

Neck Entry Nozzle system so that the nozzle enter inside the container before filling to avoid spillage

12 feet conveyor with 4 Inches stainless steel slats

Container along with electric motor for main drive and conveyor reduction gear box and variable frequency drive

Mechanically operated Nozzle Up-Down movement & Pneumatically stopper gates for bottle entry and exit.

In built memory to store 25 filling slate

Filling accuracy of el- 0.25%

Power 415 Volts 3 phase 5EI

Mechanical Piston Filling Machine

Mechanical Piston Filling Machine

Our Mechanical Piston Filling Machines are precisely designed to meet the specific requirements of the clients in most satisfactory manner. The robust construction and long operational life have made them hugely popular among clients.

Specifications

Drip free nozzles with filling range of 100ml to 1000 ml to 500 ml to 5000ml (Different capacity available)

Available from 4 head to 10 head

Mitsubishi make plc system with 4" Touch Screen and VFD control for conveyor speed control.

Contact parts in Stainless steel 304 quality

Body frame made up of Stainless steel

Capable of automatic intake of empty bottles in container on to the filling station and discharge after filling bottles with the help of stop and release lever pneumatically operated

Neck Entry Nozzle system so that the nozzle enter inside the container before filling to avoid spillage

12 feet conveyor with 4 Inches stainless steel slats

Container along with electric motor for main drive and conveyor reduction gear box and variable frequency drive

Mechanically operated Nozzle Up-Down movement & Pneumatically stopper gates for bottle entry and exit.

In built memory to store 25 filling slate

Filling accuracy of el- 0.25%

Power 415 Volts 3 phase 5EI Hz.

Volumetric Filling Machine

Product Description

[Volumetric Filling Machine] We are a reliable Manufacturer and Exporter of Volumetric Filling Machine, which is made from high quality raw materials. Volumetric Filling Machine is appreciated for longer working life and robust frame amidst the clients across the globe. This machine can be availed at competitive prices.

Features

High performance

Longer working life

Low maintenance cost

Easy to operate

Automatic Engine Oil Filling Machine

Description / Specification of Automatic Engine Oil Filling Machine

We are involved in offering a wide range of Automatic Engine Oil Filling Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Automatic Engine Oil Filling Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Inline Gear Pump Filling Machine

We are the preeminent Manufacturer and Exporter of Inline Gear Pump Filling Machine, which are diligently designed by the skilled engineers. They have incorporated various efficiency-increasing features in our Inline Gear Pump Filling Machine, which have assured the clients in regard of their ability to perform in the hardcore industrial applications.

Advantages

- Simple in design

- Easy operation

- Highly accurate

- Longer life

- High efficiency

Specifications

- Drip free nozzle with filling range of 100ml to 500ml

- Available from 4 head to 12 head

- Mitsubishi make plc system with T" Touch Screen and VFD control for conveyor speed control

- Contact parts in stainless steel 304 quality

- Body frame made up of Stain lees steel

- Pneumatically operated stopper Gates for bottle entry and exit

- In built memory to store 25 filling setting date

- Filling accuracy of -/+ 0.15%

- Setting of Volume, Speed of filling through PLC

Time Flow Filling Machines

Our company has achieved expertise in the Manufacturing and Exporting of Time Flow Filling Machine. Time Flow Filling Machine is used for filling different kinds of Liquids in various industries. This machine is well-appreciated among the clients for its high performance and durability. We are renowned as the trusted Manufacturer and Exporter of Time Flow Filling Machine.

Specialty

- Automatic operation

- Durability

- Anti- corrosive

- High performance

Features

- Drip free nozzles with filling range of 100ml to 500Dml with drip tray for accidental drip.

- Available from 4 head to 20 head

- Mitsubishi make plc system with 4" Touch Screen and VFD for conveyor speed control.

- Contact parts in Stainless steel 304 quality

- Body frame made up of M.S. with powder coating or stainless steel

- Neck Entry Nozzle system so that the nozzle enter inside the container before filling to avoid spillage

- 12 feet conveyor with 6 Inches stainless steel slate

- Pneumatically operated Nozzle Up Down movement E stopper Gates for bottle entry and emit

- In built memory to store 25 filling setting date

- Filling accuracy of +l'- 0.25%

- Power 415 Volts 3 phase SI1 Hz.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.