FIBROGRATS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FIBROGRATS P.LTD.

Frp Storage Tanks

Fibrograts offer a wide range of solutions for storing fluids or solids. These solutions are made out of full FRP material or Dual Laminate thermoplastic liner such as PP, PVC, CPVC, ECTFE, PVDF, FEP, TFM etc. in combination with FRP. The choice of material makes storage tanks easy to install in different chemical environments. From experience we know that every application has its own specific requirements. Fibrograts’ FRP storage tanks include detailed design, engineering, manufacturing, transportation and installation of all components.

FRP and Dual Laminate storage solutions:

- Horizontal FRP storage tanks (with or without insulation)

- Vertical FRP storage tanks (with or without insulation)

- FRP Acid Storage tanks

- Chemical FRP storage tanks

- Underground FRP storage tanks (e.g. fuel)

- Ultra-pure water FRP storage tanks (high purity)

- Water and wastewater FRP storage tanks

Fibrograts’ FRP and dual laminate storage tanks can be equipped with numerous accessories such as valves, level indicators, load cells, RTDs, Thermocouples, reinforcement of steel or FRP, platforms, vent scrubbers, ladders, railings, walkways, pumps, agitators, stirrers etc.

We are manufacturing storage tanks in various shapes and configuration like Cylindrical (vertical & horizontal), Square, Rectangular with flat top & bottom or conical top & bottom or dish ends by hand-layup process. Storage tanks are available in capacities ranging from 1 m3 to 400 m3. Generally tanks upto 150 m3 are made at our factory and beyond that are made at

Frp Reaction Vessels

We manufacture Process Vessels / Reaction Vessels of various sizes and shapes as per the client’s specifications, ranging from 500 ltrs, to 1,00,000 Itrs capacity with conical, dished or flat bottom and top. Selection of resin & glass fibre depends on chemical, temperature and pressure conditions of the reaction / process requirement.

Our strong in house engineering team can design equipment based on above parameters & furnish detailed fabrication drawings for client’s approval. Reaction vessels can be made either entirely in FRP with superior chemical resistant resins like Bisphenol or Vinyl Ester or there can be multiple choices for a thermoplastic liner. The engineering team can design the tank based on the chemical corrosion requirement of the equipment. PP, PVC, PVDF, HDPE or CPVC are used commonly with thickness ranging from 2mm to 5mm. If required, we offer reaction vessels that consist of MS structure that holds the vessel and structural arrangement on top for agitator and gear box assembly. We also provide stirrers, cooling or heating coil made out of different MOCs as per the requirement.

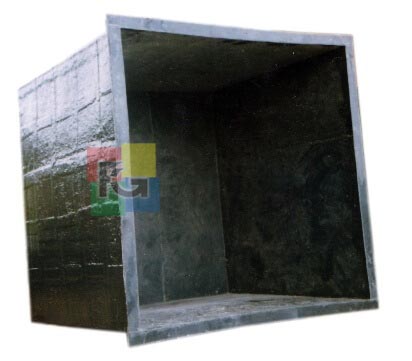

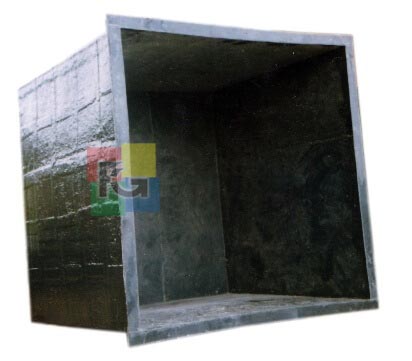

Frp Rectangular Tanks

For varying applications like Fat Traps, Electroplating & pickling of metal parts, storage, etc. Fibrograts rectangular FRP tanks find use in varying sectors across industry. Owing to high strength, long life & corrosion resistance these tanks are an excellent solution for corroding metal containers.

Frp Chimneys

For over 20 years, we at Plast-O-Fibre & Fibrograts have been expertly designing, fabricating, manufacturing and installing FRP Chimneys & PP-FRP Chimneys for corrosive applications. Industries such as thermal power plants, fertilizer industries, Pulp & Paper, Metals & Mining, Chemical Processing FRP Chimneys/ PP-FRP Chimneys in process systems in which FRP has superior corrosion resistance over metal chimneys. These FRP Chimneys & PP-FRP Chimneys are more economical & lighter in weight than metallic stacks. We also supply ducts required at inlet & outlet of stack.

We can supply stacks up to heights of 100m & for temperatures upto 200 deg C.

Frp Gratings

FibroGrats Fibreglass grating is an integral construction – single piece fiberglass roving reinforced with unsaturated polyester (FRP) / Vinyl Ester (FRVE) / Bisphenol (FRB) typically composed of 60-65% resin by weight and immensely strong continuous glass fibers manufactured by a specially designed process that provides a property of good mechanical and corrosion resistance. These are safe & ideal for chemically corrosive environment having long maintenance free life.

FRP gratings find huge applications in following structures

- Platforms

- Stairs & Landings

- Walkways

- Offshore / Onshore Platforms

- Covers of various types of Tanks and Vessels

- Flooring in and around electrical panels

- Flooring in acid washing areas

- Filter plates

FRP Gratings are available in various surface finishes & colours, most commonly being used are dark grey & yellow.

FRP Chequered plates are one of our unique products. It is moulded in single piece providing best replacement of MS / GI Chequered plate.

Frp Cable Trays

An FRP Cable Tray System is a unit or assembly of units or sections and associated fittings forming a rigid structural system used to securely fasten or support cables and raceways.

Manufactured by a continuous pultrusion molding process with a glass 60-65%, these FRP Cable Trays are a safe, dependable, life long and a cost effective solution to route and support cables.

Almost one third than Steel and one fourth than Aluminium in weight, FRP Cable Trays provide flexibility in modifying and changing electrical circuits and these trays can easily combine with other wiring methods.

Types

- Pultruded FRP Cable Trays – These are solid bottom / perforated trays used for light loads like instrumentation and control cables & for transition from cable trays to individual control points. Available in widths of 25mm to 300mm

- Ladder FRP Cable Trays – Used for heavy duty cables, these trays have solid side rails joined by rectangular or I shaped rungs at uniform spacing. Available in widths from 150mm to 1500mm

Frp Sheets

Features of FRP Sheets:

- Corrosion resistant: Do not rust and corrode unlike metallic (G.I.) Sheets

- Excellent finish from both sides

- Weather durability

- Upper side is with UV coating

- Resistant to acid/alkali fumes

- Free from problems of cracking, warping

- Expected life: 15 to 20 years

- Rust proof

- Water proof

- Fire retardant grades are available

- Light weight, ease of installation yet strong mechanical strength

- High tensile strength & High impact strength

Specifications:

- Thickness: 0.8mm, 1.2mm, 1.5mm, 2mm, 2.5 mm, 3 mm, 4mm, 5mm

- Colors : clear, sky blue, light green, any other as required

- Profiles : All types of major available profiles & Corrugated patterns

- Length : Cut as per customers requirement subject to suitability of transportation

Frp Drain Covers

Theft of iron manhole covers & heavy breakages in local cement manhole covers is an age old problem. To get rid of such problems, we have introduced FRP manhole covers & FRP drain covers. These FRP manhole covers have similar strength as cast iron but lower coefficient of expansion, bending, vibration transmissions & noise. Also they do not have any scrap value hence theft free.

Available in slip resistant finish, these FRP Manhole Covers come with anti-skid surface that aids in preventing accidents related to slipping. Further, the fire retardant and thermally insulated finish of these manhole covers also provide for durable and lasting usage. Some of the product featured are – resistant to microbial growth, featuring high strength to weight ratio, impact & UV resistant, single piece molded type construction.

These FRP Manhole Covers are available in standard sizes with load bearing capacity ranging from 40MT to 200MT (light duty, medium duty & heavy duty). They are circular, square & rectangular in shapes.

Frp Hand Rails

FRP handrail systems are easily assembled and installed from durable, prefabricated pultruded fiberglass components. These FRP Hand Rails are quick and easy to assemble. The system can be prefabricated and shipped to the site and installed on site with simple hand tools.

FRP Handrail options include horizontal or inclined FRP railing systems with two or three rails suitable for different types of structures and applications. These include safety barriers, shop fittings, as well as extreme environments such as mining, oil and gas, electrical sub-stations, and chemical plants. They can also be combined with our other FRP structures, such as FRP platforms.

Frp Lining

Description / Specification of Frp Lining

We are involved in offering a wide range of Frp Lining to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Frp Lining. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Frp Coating

An inherent manufacturing defect or a damage prior or after installation of a Tank, flooring system, etc. of metal or concrete may lead to leakages and spillage of materials creating dangerous situations. FRP Lining is an excellent solution for such cases where complete replacement involves huge resources mainly time and cost.

We possess expertise in FRP Lining inside and outside MS,SS & RCC tanks

Scrubbing System For Fertilizer Plants

We concentrate on designing economical, simple and effective processes of separating solid particles from waste gases and liquids (like oil, grease etc)/gases which are harmful for environment before a waste is expelled into air. All our systems are designed by well experienced engineers and put forth a history of successful and satisfactory operation.

Specially designed for Fertilizer Industries, we manufacture, install and maintain the complete fume scrubbing systems, comprising of equipments like scrubbers, ducts, blowers, separators, chimneys, etc

Soap Stock Splitting Plants

Description / Specification of Soap Stock Splitting Plants

We are involved in offering a wide range of Soap Stock Splitting Plants to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Soap Stock Splitting Plants. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Acid Oil Splitting Plants

Soap stock is a byproduct of soap, resin acids and wax materials that are separated as a result of washing and neutralization of free fatty acids with caustic and in refining of vegetable raw oil. It contains water and low amount of oil. It is obtained during elimination of free fatty acids (alkaline refining) by caustic soda neutralization of raw oils. It is a mixture of fatty acid soaps, salts, phospholipids, impurities and entrained neutral oil. Soap Stock Splitting is done with Sulphuric / Hydrochloric acid to obtain Acid oil.

As a result of usage of acid, soap stock splitting process is a highly corrosive process. Designed under technical expertise of Mr. Ashok Jain (Promoter of M/S Plasto-Fibre Ind), we offer a very specialized leak proof & corrosion proof Soap Stock Splitting Plant / Acid oil plant. First Soap Stock Splitting / Acid Oil Plant we ever manufacture in fiberglass was way back in 1990.

With over 25 years of experience in designing, manufacturing & commissioning of over 200 Soap Stock Splitting plants / Acid oil plants for all sizes of refineries & our plants have over 95% efficiency with reduced acid consumption, low quantity of sludge & fumes, lower acidity of effluent & high quantity of acid oil with enhanced quality. Our Soap Stock Splitting Plants / Acid Oil Plants contain specially designed corrosion free pipelines, pumps, valves etc.

Acid Dilution Systems

Description / Specification of Acid Dilution Systems

We are involved in offering a wide range of Acid Dilution Systems to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Acid Dilution Systems. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Distilled Fatty Acid Plants

Fatty acids occur widely in nature & are derived from commodity oils and fats. They find major use for food and nutrition applications & in oleochemical industry to produce soaps, detergents, personal care products, lubricants, paints and biodiesel. The largest vegetable oil sources are the oilseed crops (soybean, rapeseed, sunflower, and cottonseed)

Distilled fatty acid contains a mixture of palmatic acid, stearic acid, oleic acid, linoleic acid & linoleneic acid. These are mixture of saturated and unsaturated fatty acid with variable percentage and depending upon this percentage iodine value of the mixed fatty acid is decided

Brief description of the process is mentioned below:

Feedstock obtained from splitting of Fats & Oils / Acid Oil is pretreated & degumming is carried out to separate gums which are present as impurities. Degummed acid oil / feedstock is decolorized & hydrolyzed or split in an autoclave to obtain crude fatty acid.

After mixing appropriate & pre-calculated quantities of crude fatty acid from autoclave & DO of refinery, both are transferred to a separator. Further the mixture is passed through a degasser in which degasification & removal of colour generating low boiling impurities take place.

Finally the degassed crude fatty acid is transferred into main distillation kettle for distillation under vacuum at lowest possible temperature.

Key highlights of the process are:

- Final colour of the distilled fatty acid is less than 5 units on Gardner scale

- Optimizes the recovery of heat

- System is designed to handle worst possible feedstocks to produce high grade Distilled fatty acids.

- Our process removes all odors, colours & fractions

- Highest efficiency of final distilled Fatty acid.

Liquid Lecithin Plants

Lecithin is a naturally occurring group of Phospholipids found in almost every living cell. It is a vital, multifunctional, active substance used in manufacturing variety of food products, neutraceutical & healthcare products, cosmetics & various feed formulations.

Normally Lecithin is used as an Emulsifier, Wetting Agent, Dispersing Agent, Stabilizing Agent, Viscosity Reducing Agent, Anti-spattering Agent, Mixing and Blending Agent, Release Agent, Conditioning, Lipotropic, Surface Active Agent & as an Emollient & Anti-Oxidant.

Lecithin is a by-product in refining of vegetable oils. During the usual batch degumming process the crude oil is heated to about 70 °C, mixed with 2% water and subjected to thorough stirring for about half an hour to an hour. This addition of water to the oil hydrates the polar lipids in the oil, making them insoluble. The resulting lecithin is then separated by centrifugation & also dried.

The composition and quality of the crude lecithin product are considerably influenced by the quality and origin of the oilseeds, as well as the conditions during the de-gumming process.

We are Manufacturing Lecithin Plant with latest technology in which gums are processed at 65-75 deg. C which gives best quality Lecithin with maximum yield. Also the evaporator / heat exchanger we use is designed to make homogenous lecithin. Our plant is complete PLC based plant with single point operations.

We can design liquid lecithin plants for Rice bran gums, sunflower gums, soya gums, etc

Powder Lecithin Plants

Similar to liquid Lecithin, Powdered lecithin is ideal for use in the Food, Nutraceutical & Pharmaceutical industry. The powdered form is a wax like ingredient and it is obtained from Soyabean, Sunflower, Rape Seed and Rice Bran. It is an ideal thickening addition to food and cosmetic products and enhances product shelf life owing to its preservative nature. Its benefit over liquid lecithin is its ability to blend into almost any set of ingredients.

The extraction is done using acetone as solvent. The lecithin after the pre-treatment is extracted in a specially designed and efficient continuous counter current extraction system (Liquid –Liquid Extraction) with acetone to precipitate the acetone insolubles. After extraction, the miscella is withdrawn into a miscella tank and the thick solid Slurry is transferred to a d-canter feed tank. The miscella is pumped to acetone recovery system, to recover the acetone for reuse. The soya oil remaining after acetone recovery is saleable.

The thick solid –slurry transferred to the d-canter feed tank is decanted in a high speed centrifuge to separate the acetone and the solids acetone goes to the miscalla tank and solids are taken for drying.

Drying of the acetone wet solids is done in a specially designed two stage closed loop continuous fluidized bed dryer. The Drier comes with a nitrogen generator and is totally a PLC controlled system. The other utilities required for the dry steam and chilled brine The deoiled lecithin powder coming out of the drying system is then sieved, micronized and packed.

The miscella generated after extraction is taken to a four stage acetone recovery system. This system is very critical in terms of recovery of acetone and minimizing the distillation losses of acetone. The recovered acetone is condensed and recycled to extraction process.

A granulator can be provided for manufacture of granular lecithin

Key Features of Our Plant:

- Robust plant and machinery with equipments designed & manufactured with latest technology

- Automated process control plant with minimum manual intervention

- Online controls for drying and packing of product

- Excellent milling system to get desired particle size

- Low Acetone losses & optimum utility consumption

- Reuse of acetone

- Reduced bleaching plant time cycle

- Minimum power wastage, Energy efficient plants

- Advance packing and storage techniques

- Extraction process control

- Consistency in quality & quantity of output

- No effluent generation

Frp Manhole Covers

Description / Specification of Frp Manhole Covers

We are involved in offering a wide range of Frp Manhole Covers to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Frp Manhole Covers. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Frp Roofing Sheets

Description / Specification of Frp Roofing Sheets

We are involved in offering a wide range of Frp Roofing Sheets to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Frp Roofing Sheets. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.