FIBROGRATS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FIBROGRATS P.LTD.

Liquid Lecithin Plants

Lecithin is a naturally occurring group of Phospholipids found in almost every living cell. It is a vital, multifunctional, active substance used in manufacturing variety of food products, neutraceutical & healthcare products, cosmetics & various feed formulations.

Normally Lecithin is used as an Emulsifier, Wetting Agent, Dispersing Agent, Stabilizing Agent, Viscosity Reducing Agent, Anti-spattering Agent, Mixing and Blending Agent, Release Agent, Conditioning, Lipotropic, Surface Active Agent & as an Emollient & Anti-Oxidant.

Lecithin is a by-product in refining of vegetable oils. During the usual batch degumming process the crude oil is heated to about 70 °C, mixed with 2% water and subjected to thorough stirring for about half an hour to an hour. This addition of water to the oil hydrates the polar lipids in the oil, making them insoluble. The resulting lecithin is then separated by centrifugation & also dried.

The composition and quality of the crude lecithin product are considerably influenced by the quality and origin of the oilseeds, as well as the conditions during the de-gumming process.

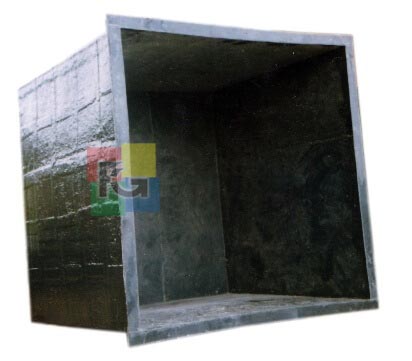

We are Manufacturing Lecithin Plant with latest technology in which gums are processed at 65-75 deg. C which gives best quality Lecithin with maximum yield. Also the evaporator / heat exchanger we use is designed to make homogenous lecithin. Our plant is complete PLC based plant with single point operations.

We can design liquid lecithin plants for Rice bran gums, sunflower gums, soya gums, etc

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.