FIBROGRATS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FIBROGRATS P.LTD.

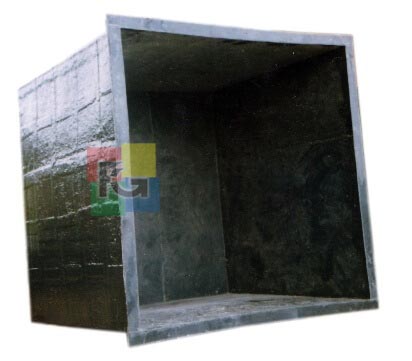

Frp Reaction Vessels

We manufacture Process Vessels / Reaction Vessels of various sizes and shapes as per the client’s specifications, ranging from 500 ltrs, to 1,00,000 Itrs capacity with conical, dished or flat bottom and top. Selection of resin & glass fibre depends on chemical, temperature and pressure conditions of the reaction / process requirement.

Our strong in house engineering team can design equipment based on above parameters & furnish detailed fabrication drawings for client’s approval. Reaction vessels can be made either entirely in FRP with superior chemical resistant resins like Bisphenol or Vinyl Ester or there can be multiple choices for a thermoplastic liner. The engineering team can design the tank based on the chemical corrosion requirement of the equipment. PP, PVC, PVDF, HDPE or CPVC are used commonly with thickness ranging from 2mm to 5mm. If required, we offer reaction vessels that consist of MS structure that holds the vessel and structural arrangement on top for agitator and gear box assembly. We also provide stirrers, cooling or heating coil made out of different MOCs as per the requirement.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.