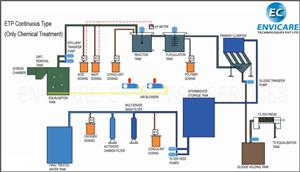

E.T.P. Containerised Type

Capacity : 25 – 150 KLD, As per client Requirement

Tecnology : Physical / Chemical / Biological / UlFiltration

Features :

- Semi-automatic Operation.

- Required less space as compared to conventional design.

- Very Compact and Great aesthetic.

- Reduced Installation and commissioning time on site.

- Plug and play operation.

- Easy Dismantling and transportation.

- Made to order product.

- Civil Work – Collection Tank and Container Foundation.

Typical Industries : Chemical, Pharmaceuticals, Automobiles, etc.