ENERGYPACK BOILERS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ENERGYPACK BOILERS P.LTD.

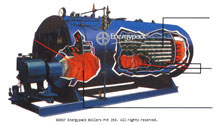

I. B. R. Oil Fired Steam Boiler Ebpl Series

ENERGYPACK Boilers is one of the Leading Industrial Boiler Manufacturers, Suppliers and Exporter of three pass wet back, horizontal, smoke tube type fusion welded Boilers which are made to IBR / DIN / BS / ASME code. Components are Engineered for maximum safety, Highest Efficiency, dependability and quite operation. Wet back Models eliminate rear end refractory and its inherent maintenance cost, reduces stress of rear tube sheet and repeated ligament cracking, radiant heat is eliminated, increasing tube life and reducing heat loss from rear turn around.

I.B.R. Solid Fuel Fired Steam Boiler (Ifb) Ebpl Series

Ebpl Series 49490.jpg)

ENERGYPACK IBR Solid Fuel Fired Steam Boilers (IFB) are three pass wet pack, horizontal, smoke tube type fusion welded boiler. They are made to IBR / DIN / BS / ASME code as per requirement of clients. Components are Engineered for maximum safety, Highest Efficiency, dependability and quite operation. Wet back Models eliminate rear end refractory and its inherent maintenance cost, reduces stress of rear tube sheet and ligament cracking, The radiant heat is eliminated lengthening tube life and reducing heat loss.

Our integral furnace submerged below water level ensuring complete utilization of heat liberated in the furnace. Apart from the Coal & Lignite the Solid Fuel Fired boiler can also be burnt with Biomass, Briquettes, Groundnut Shells, Coconut Shells, Cashew Shells, Sugarcane and Wood husk to ensure environment friendly flue.

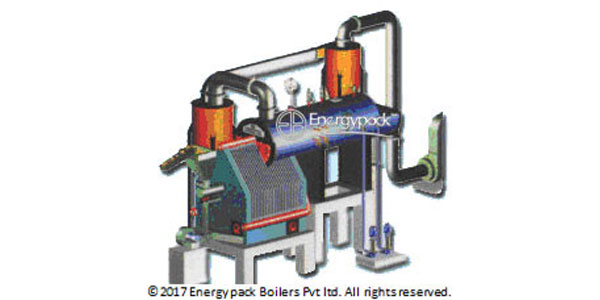

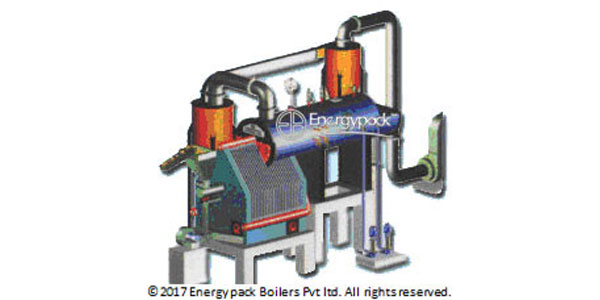

I. B. R. Agro Waste Fired Steam Boiler Ebpl Series

Energypack Agrowaste Fired Boilers & Biomass Fired Boilers have three pass water wall construction which are horizontal type fussion welded with Water / Air pre heater. Biomass Fired Boilers have furnance formed with water wall construction completely submerged in water. Boilers are made to IBR/DIN/BS/ASME Code. The IBR Steam Boilers are designed for maximum safety, dependability, quite operation and to burn solid agrowaste with low calorific value.

The IBR Steam Boiler with an external furnace compact design can be installed easily as they come with complete insulation refractory on site for ensuring minimum installtion time. These Biomass Fired Boilers assure low ash content and residual ash removal due to our user friendly ash removal design becomes very easy. Extra grate area and furnace length ensure optimum efficiency in our Agro Waste \ Biomass Fired Boilers.

Waste Heat Recovery Thermic Fluid Heater

Description / Specification of Waste Heat Recovery Thermic Fluid Heater

We are involved in offering a wide range of Waste Heat Recovery Thermic Fluid Heater to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Waste Heat Recovery Thermic Fluid Heater. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

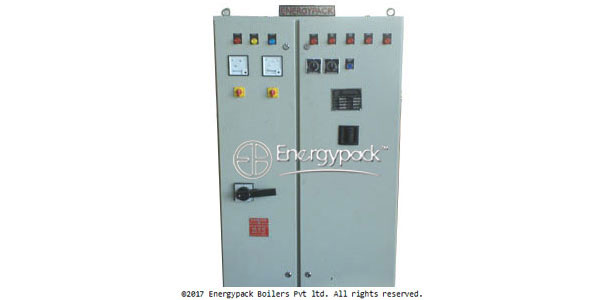

Electrical Thermic Fluid Heater

Description / Specification of Electrical Thermic Fluid Heater

We are involved in offering a wide range of Electrical Thermic Fluid Heater to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Electrical Thermic Fluid Heater. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Coal And Briquette Biomass Fired Thermic Fluid Heater

ENERGYPACK external furnace horizontal coil type forced circulation with ID & FD fan for solid fuel firing system having higher furnace volume & grate area to burn various low calorific fuel like Cashew Shells, Coconut Shells, Groundnut Waste, Chicken Dropping mixed with Briquettes / Coal / Wood with three to four passes of flue gases for better efficiency of the complete system with air preheater.

Gas Fired Thermic Fluid Heater

ENERGYPACK gas fired thermic fluid heater are designed with unique liquid sealing arrangement to prevent oxidation of thermic oil, which increase the life of oil. Gas fired thermic fluid heater are fabricated in both vertical & horizontal design as per the client requirement & availability of space. Standard Operating Temperature up to 300 deg C.

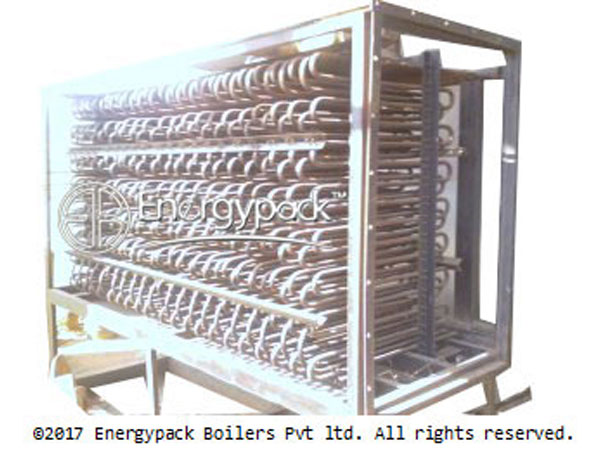

Economiser Epe Series

Waste Heat Recovery System To Pre Heat The Boiler Feed Water From Flue Gas Heat Capacity To Suit Client Requirement .These are known for their higher efficiency & increases the performance of the boilers.

Our Economisers are operator friendly with easy acess to cleaning and mainteanance.

Pressure Vessel And Heat Exchanger

Description / Specification of Pressure Vessel And Heat Exchanger

We are involved in offering a wide range of Pressure Vessel And Heat Exchanger to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Pressure Vessel And Heat Exchanger. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Electric Steam Operated De Waxing Boiler Autoclave

Our Dewaxing Boiler Autoclaves are designed specifically for the investment casting foundries. This is fully indigenous self contained autoclave wih provision for Electrical, Diesel, Gas and Solid fuel steam generation which becomes economical efficient and easy to maintain. Our fast and safe Semi automatic door closing system not only ensures maximum safety of people working around it but also minimises cracking of shells due to instant thermal transfer. The Dewaxing Boiler Autoclave machine is complete with PLC or Hard wire automation for convenient control of operation and selection of optimum and variable cycle time as per mould size, wax quality and batch size. We also provide touch based Human Machine Interface (HMI) for comfortable and quick operations.

Chimney And Accessories

We Design and Manufacture Chimneys as per specific boiler requirements as per the volume and the velocity of the exhaust flue gases. Apart from the Guy wire supported chimneys we also manufacture self supported chimneys as per IS 6533.

We have supplied different kinds of flues upto 1500mm top diameter and 50meters height in sections and also fully welded with complete alignment Predespatch inspection in factory.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

Ebpl Series 49490.jpg)