ELECTROMECH MATERIAL HANDLING SYSTEMS INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELECTROMECH MATERIAL HANDLING SYSTEMS INDIA P.LTD.

Single Girder Cranes

ElectroMech manufactures Single Girder Overhead Cranes in SWLs ranging from 250kg to 20MT in different configurations. Typically, beam or box type main girders are used depending on the span of the crane. A castellated girder structure can also be employed to save weight or to reduce the effect of wind forces for outdoor duty cranes. We specialise in custom built long span cranes where finite element analysis is used to optimise the natural frequency and design a robust structure for smooth operation.

These cranes can be offered with a range of standard electric wire rope hoists or chain hoists depending on the your requirement. Low headroom hoists are used where vertical space is at a premium to achieve maximum lift. Precise control of all motions is achieved through Variable Frequency Drives.Additionally, we also supply Single Girder Cranes in a ‘torsion box’ type arrangement, featuring a cantilever mounted ABUS hoist.

Double Girder Cranes

ElectroMech manufactures Double Girder Overhead cranes in SWLs ranging from 1MT to more than 200MT. These cranes can either incorporate standard ABUS crabs up to a SWL of 100MT or fully customized open winch type crabs. ElectroMech can supply fully customised Double Girder Cranes as your requirements for different duty cycles and a diverse range of applications. Double Girder Cranes can be offered for a very large range of spans, heights of lift as well as customizable speeds depending on your application. They can also be provided with multiple hoisting trolleys running on the same bridge or auxiliary hoisting mechanisms on the main trolley.

Precise control of all motions is achieved through Variable Frequency Drives. We also offer Double Girder Overhead Cranes for the steel industry, built according to IS 4137 norms. These cranes are built to be capable of withstanding extreme requirements of operating speeds and operating conditions.

Underslung Cranes

ElectroMech manufactures Single Girder as well as Double Girder cranes in an Underslung configuration Such cranes find applications where the headroom in a factory is limited or the structure does not allow any other means of supporting the crane other from the roof.

Typically, Underslung Overhead cranes range from 250kg to 10MT, however higher capacity Underslung Cranes can also be manufactured as per your requirements.

Precise control of all motions is achieved through Variable Frequency Drives.

Jib Cranes

Jib cranes assist the staff, multiplying human efforts and are an invaluable material handling solutionfor a standalone workstation or machine assembly area. They are useful especially for loading or unloading work pieces or machine tools or even loading or unloading of trucks. Dedicated jib cranes for a single workstation or group of workstations allows for efficient material handling by reducing wait time for an overhead crane.

Column mounted Jib Cranes are necessary when no other appropriate support near a workstation is available. Wall mounted Jib Cranes are ideal solutions for workstations located near walls or vertical structures.

ElectroMech designs and manufactures Jib Cranes to suit specific requirements, handling loads up to 6.3 MT precisely and effortlessly. Standard Electric Wire Rope Hoists or Chain Hoists do the lifting and moving duty on these Jib Cranes.

Wall Traveling Cranes

The ABUS single girder wall travelling crane is designed for operation on a lower level beneath a large travelling crane system. These cranes provide additional handling possibilities and ensure smooth and trouble free material handling between different working areas. A wall travelling crane installed at right angles across the hall can serve several workstations. ABUS single girder wall travelling cranes are available for load capacities up to 5MT with outreach up to 10m.

Wall travelling cranes ensure effortless handling of loads and can feed multiple work stations. It is possible to mount several cranes on the same rail.

Light Weight Cranes

The ABUS HB System combining the effectiveness of a stationary hoist with the mobility of an overhead crane, efficiently and cost-effectively. The system is indispensable for enhancing work efficiency at workplaces as such warehouses, workshops, assembly lines, tool rooms or clean environments.

HB-System offers tailor-made modular solutions. The components of the system are modular and can be combined to build a system which the application demands. All HB-Systems feature an extremely low-build design, ensuring that maximum hook height can be reached in the available space. Three types of profiles cover a load capacity range up to 2 MT All electrical connections are made using an easy plug-in connector system. The system can be adapted and individually fitted to almost any type of room or ceiling design.

Gantry Cranes

Gantry cranes or Goliath Cranes are very versatile cranes used typically for activities in steel stock yards, pre-cast segment yards, construction sites and other outdoor applications. They are also the right material handling solution in cases where the existing factory structure cannot bear the wheel loads of an overhead crane; loads need to be handled outside the crane span as in the case of an overhang on either side of the rails or where there is a requirement to relocate the crane after work at a particular site is completed. ElectroMech Gantry cranes have proven themselves to be robust and more than capable of with standing the rigours of a variety of applications from steel yards to construction sites.

ElectroMech manufactures gantry cranes in Single Girder and double Girder configurations depending on the requirement. These cranes can be completely customized for SWL, span, lifting height, speeds and class of duty depending on the application. Hoisting is through standard hoists for Single Girder Gantry cranes. For Double Girder Gantry cranes, either a standard ABUS crab or a fully customized open winch type crabs is used. They can also be provided with multiple hoisting trolleys running on the same bridge or auxiliary hoisting mechanisms on the main trolley. Precise control of all motions is achieved through Variable Frequency Drives. Depending on the site requirement, power supply is through a cable reeling drum or an on board generator for outdoor gantry cranes.

Semi Gantry Cranes

A Semi Gantry Crane is a variation of a Gantry crane in which one end carriage of the crane travels on the regular gantry rail while the opposite end-carriage will travel on a rail mounted typically on the ground or at a lower elevation.

A semi Gantry crane is used in applications such as a tool room where part utilization of the bay is required, or in outdoor sites where a gantry rail can be installed on the side of an existing structure.

Tunnel Mucking Cranes

ElectroMech has developed a unique and cost-effective bulk material handling system for extraction and disposal of overburden generated during construction of tunnels.

These systems can very efficiently remove overburden generated during construction of deep shafts with access tunnels as well as the overburden generated during the tunneling operations itself.

The typical heights of lift for such systems are in the range of 50m to 300m. The typical hoisting speeds are in the range of 30 m/min to 40 m/min. Several such systems designed, manufactured and commissioned by ElectroMech are being used by several major construction companies and are operational at various construction sites across the country.

Stacker Cranes

Whether a warehouse or a manufacturing facility, optimum utilization of space by volume, rather than floor area for storage of material is critical. Where substantial volumes of raw material, components or finished goods need to be stored, a stacker crane facilitiates swift retrieval and stocking, offering an ideal solution. This is particularly pertinent in metros, with spiraling cost of land and construction or an existing facility where the existing space needs to be utilised.

ElectroMech stacker cranes can be customised to your requirement for optimum space utilization and efficient warehousing operations.

Indigenously designed and manufactured by ElectroMech, a stacker crane is a combination of an EOT crane and forklift. These systems offer several operational advantages such as narrower aisles as compared to the space required by a forklift to manoeuvre. The crane is supported by the racks themselves, hence no additional structure is required. Being electrically operated, no harmful exhaust fumes are emitted onto the work environment; further, there is no down time required to charge batteries. The structe of the system, with a crane mounted on the racks, is inherently safe, with no danger of tipping over.

ElectroMech stacker cranes have been supplied to several clients across the globe.

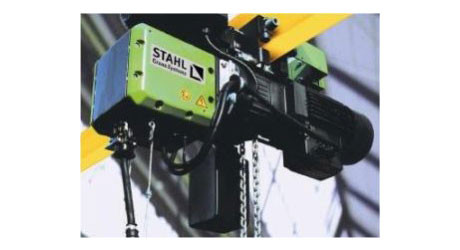

Explosion Protected Electric Chain Hoists

ElectroMech is the exclusive India partner for STAHL Crane Systems, Germanys range of Explosion protected crane and crane components. Explosion protected crane technology is used in industries such as chemicals, oil & gas, paints and pharmaceuticals. STAHL Crane Systems is the pioneer for explosion-protected crane technology; has been in the field since 1926 and is currently the global market leader for explosion protected hoists and cranes.

Explosion protected hoists and crane components from STAHL Crane Systems meet European ATEX regulations and have also been certified in compliance with the IECEx scheme.

STAHL explosion protected chain hoists are protected against gas and dust explosions; certified in accordance with ATEX for Zone 1 (gas) and Zone 21 (dust) and can be used for Zone 2 (gas) and Zone 22 (dust). Patented suspension directly on the chain guide ensures maximum safety while their compact design requires minimal space.

Twin speeds in hoisting and travel offer precise operations. These hoists are maintenance friendly and cost effective due to low wear brake and slipping clutch and have a long service life in accordance with FEM.

Explosion Protected Wire Rope Hoists

ElectroMech is the exclusive India partner for STAHL Crane Systems, Germanys range of Explosion protected crane and crane components. Explosion protected crane technology is used in industries such as chemicals, oil & gas, paints and pharmaceuticals. STAHL Crane Systems is the pioneer for explosion-protected crane technology; has been in the field since 1926 and is currently the global market leader for explosion protected hoists and cranes.

Explosion protected hoists and crane components from STAHL Crane Systems meet European ATEX regulations and have also been certified in compliance with the IECEx scheme.

STAHL Explosion Protected Wire Rope Hoist are specially designed for working in hazardous areas and meets ATEX requirements for Zone1 and Zone 2 or Zone 21 andZone 22.

All components come from the production facility of STAHL Crane Systems. The powerful, robust hoist motor ensures continuous performance and high duty cycle. Features such as a gearbox with lifetime lubrication, repeatedly adjustable brakes and brake wear display make the hoists maintenance friendly as well as robust.

Explosion Protected Cranes Components

ElectroMech is the exclusive India partner for STAHL Crane Systems, Germanys range of Explosion protected crane and crane components. Explosion protected crane technology is used in industries such as chemicals, oil & gas, paints and pharmaceuticals. STAHL Crane Systems is the pioneer for explosion-protected crane technology; has been in the field since 1926 and is currently the global market leader for explosion protected hoists and cranes.

Explosion protected hoists and crane components from STAHL Crane Systems meet European ATEX regulations and have also been certified in compliance with the IECEx scheme.

ElectroMech manufactures cranes using Explosion protected Crane Kits from STAHL to offer customers a completely safe material handling solution for hazardous environments.

Counterbalanced Forklift Trucks

|

Electric Chain Hoists

ElectroMech offers standard ABUS Wire Rope Hoists. In a stationary installation, with push trolleys or electric trolleys, ABUS electric chain hoists prove to be extremely useful and user-friendly. The advantages include very low headroom requirement for optimum space utilization, a standard precision lifting speed for sensitive lifting and lowering operations and brake linings with a long service life.

The hoist units are available in four different sizes to reliably handle loads from 80kg to 4 MT.

Abus Electric Wire Rope Hoist

ElectroMech offers standardized ABUS Wire Rope Hoists. With reputation for quality, reliability and affordability, ABUS Electric Wire Rope Hoists feature several advanced engineering concepts with special emphasis on safety and versatility.

ABUS Wire Rope Hoists are compact with low headroom dimensions and incorporate latest technical innovations. These hoists are produced using the most advanced technology available and continue to witness reliability, safety and durability year-after-year, from motor to rope, gearbox, brake and electronic systems. These units cover an extremely wide SWL range from 1MT to 100MT in both monorail and double girder configuration.

High Lift Winch

|

Triple Girder Cranes

|

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.