ELITE STEELS P. LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELITE STEELS P. LTD.

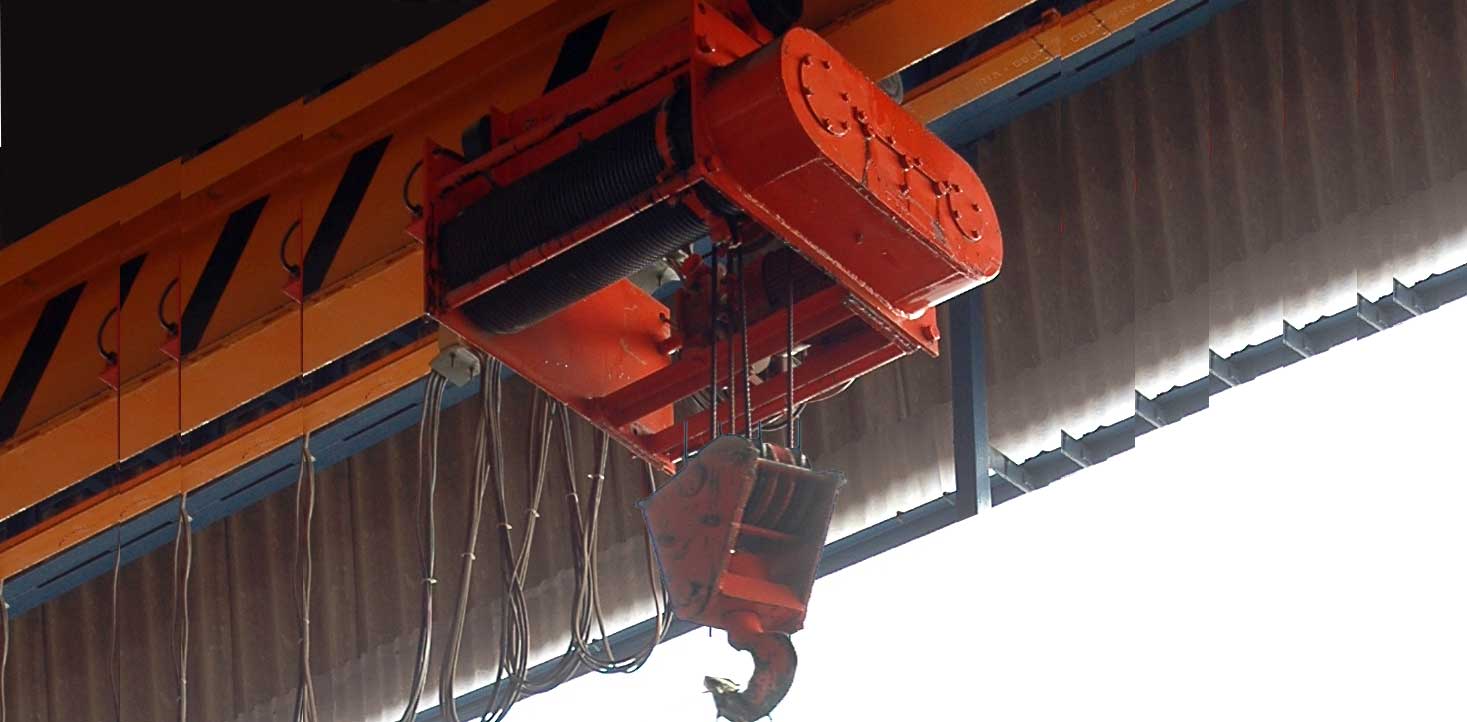

Double Girder E.O.T Cranes

Structure - 100% Radiography of all butt welding joints of bridge and carriage to ensure defect-free welding and strong and rigid structure. the material of construction conforms top IS:226 or IS:2062,and the bridge is designed

Wheel Assemblies - Trolley and crane wheels are straight treaded double flanged forged steel wheels. heat treated to achieve a depth of 15-20 mm from the surface and gradually diminishing towards the center retainingthe core properties. these wheels are supported on antifriction ball/roller bearings.

Gearing-The gear reducers are constructed either in double, triple and quadruple reduction using regged wide faced helical and spur gears that are precision cut from special alloy steel forgings and to supported between two antifriction ball/roller bearings. All gear uniot are totally enclosed with oil bath splash lubrication.

Crane Micro Drives- The spacial micro drive provides fine inches movements of hoest, trolley or crane at the rate of 5% to 20% of the rate of the main speed. The micro drive achieved by a separate gear box with unique sun and plant system gearing system fitted on the input side of main gear unit it is a positive drive and avoid the use of clutches etc. (Optional)

Double Girder European Design Compact Cranes

Design similar to European Design Cranes with better Features.

SEW / NORD German make. Geared brake Motors. Compact unit for Hoisting, CT & LT motions. All gears are hardened & ground with high efficiency, smaller size, low noise, smooth operation, Bearings are life sealed.

Drive for all motions ready to fit unit.

CT / LT motions need no bulky platform.

Combined effect is smaller trolley, smaller end carriage.

Box Girder becomes lighter.

Overall Crane Weight is less. LT Wheel load is less.

All motions are with VVVF Drives.

Power Consumption is low.

Double Grider E.O.T Cranes With Grab Bucket

Description / Specification of Double Grider E.O.T Cranes With Grab Bucket

We are involved in offering a wide range of Double Grider E.O.T Cranes With Grab Bucket to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Double Grider E.O.T Cranes With Grab Bucket. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Single Girder E.O.T Cranes

Main Girder -I beem types or box girders as per selection based upon capacity and span are fabricated as per relevent IS standerd.

Wheel Assamblies - Crane wheels are forged steel formed suitable for i beam or box selection girders.

End Carriage -From rolled selection or plate box fabricate as ter selection and options of costomer are fabricated.

LT Drive machinery- Properly selected geared brake moter or vertical gear box coupled with brake - motor drive the LT wheels.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.