ELGI ELECTRIC AND INDUSTRIES LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELGI ELECTRIC AND INDUSTRIES LTD.

Automatic Overhead Traveling Cleaner

Elgi Electric has developed a World Class Product NUGEN-XL having 22 mtrs./min. traveling speed & wheel arrangement to travel long frames with link coner with highest cleaning frequency. One OHTC can cover upto 3648 Spindle saving power and Investment. No wonder, Elgi Electric’s customers have that extra competitive edge.

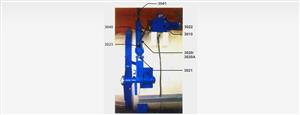

Vaccum Pump

Description / Specification of Vaccum Pump

We are involved in offering a wide range of Vaccum Pump to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Vaccum Pump. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Energy Vessel Assembly

Description / Specification of Energy Vessel Assembly

We are involved in offering a wide range of Energy Vessel Assembly to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Energy Vessel Assembly. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

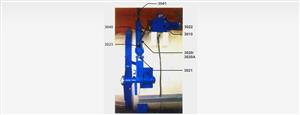

Hydraulic Power Pack Unit

Description / Specification of Hydraulic Power Pack Unit

We are involved in offering a wide range of Hydraulic Power Pack Unit to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Hydraulic Power Pack Unit. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Control Panel And Accessories

Argus Fire Control manufactures a broad-range of fire suppressing system components for all types of textile production processes threatened by fire hazards or metal contaminants. Through the use of a patented infrared detector, a spark or glowing ember is detected, instantaneously firing a suppression tank, shutting down production equipment and closing dampers to halt the spread of the fire and alerting production personnel to the incident. Experience over the years has identified a broad range of hazards in spinning mills. These include: “Hot Bales” received from cotton gins, stones in cotton bales, stray metal and wire in bales, loose metal from the production process itself, friction and choke-up, and even electrical short circuits in production equipment. Given this broad-range of hazards Argus equipment is used productively within many production processes including.

Metal Detector And Diverter For Textile Mills

The ARGUS THS/TT Metal Detector detects metal contaminants accidentally present in pipelines (i.e. in pneumatic lines), with levels of sensitivity, immunity to interference and response speeds designed to satisfy the strictest quality Control requirements.

[Metal Detector] ARGUS THS/TT Metal Detectors, designed for operation in high speed production lines, allow interception of all magnetic and non-magnetic metals, including high-resistivity stainless steel. The system is composed of an electronic control unit and an antenna which is positioned in the path of the product to be inspected. DSP (Digital Signal Processing) of the Metal Director Antenna signals allows a very high degree of sensitivity to be achieved for all metals.

Spark Detector And Diverter For Textile Mills

Fires that start in production machinery quickly spread to the material feeding pipes. If the material feeding pipes carry spark which can damage the subsequent machineries hence the mill cannot continue to operate its production machinery resulting production and monetory losses.

ARGUG FIRE CONTROL systems detect and control these fires with in 50 milliseconds. The ARGUS system uses infrared Spark Detectors to detect a single spark, activate high speed diverter, sound alarms, and shut down the production machineries.

Automatic Fire Protection System For Bale Plucker

A single spark under an automatic Bale Opener can flash over an entire cotton bale lay down in seconds. This dangerous situation can be avoided with the purchase of an ARGUS FIRE CONTROL WS-15 Fire Protection System.

ARGUS FIRE CONTROL systems detect and control these fires to protect valuable machinery and control bales. The ARGUS system uses infrared Spark Detectors located inside the bale opener to detect a single spark, activate an automatic fire extinguisher, sound alarms, and shut down the machine – all in less than 50 milliseconds.

Filtration System Fire Protection (Dry Chemical System)

27831.jpg)

ARGUS FIRE CONTROL systems detect and control these fires in only 50 milliseconds. The ARGUS system uses infrared Spark Detectors to detect a single spark, activate an automatic fire extinguisher, sound alarms, and shut down the filtration and production machinery.

Energy Saving Motors

Electric motors with improved efficiency, in combination with frequency converters can save about 7% of the total worldwide electrical energy. Roughly one quarter to one third of these savings come from the improved efficiency of the motor.

Motors from 0.37kW to 375kW make up the vast majority (approximately 90%) of installed population and are covered by the standard IS 12615:2011. This fulfills the need of the manufacturers to design motor for a global market. This standard defines four efficiency classes for nominal frequency 50Hz.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.