ELEKTROMAG DEVICES P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELEKTROMAG DEVICES P LTD.

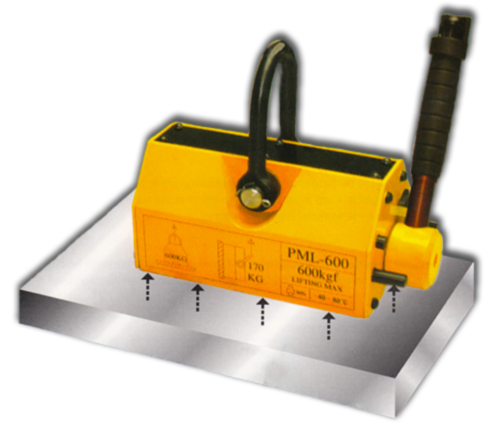

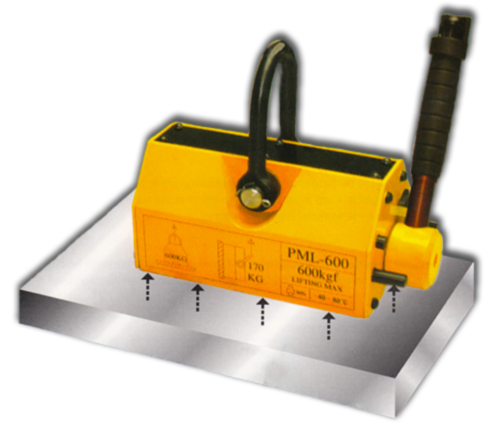

Permanent Magnetic Lifters

ELEKTROMAG Permanent Magnetic Lifters now have all the power and versatility of electro magnets with the added advantage of absolute safety and no dependence on power supply. The use of Rare Earth Magnets has resulted in powerful lifting capacity. Hence they are widely used for loading and unloading devices in factories, docks, warehouses and machine tool industries.

The safety aspects have been taken care of by providing a 3 to 1 safety factor and also a specially designed handle with safety lock. The magnets are guaranteed to retain original strength indefinitely under normal use.

One turn of the lever switches the magnet ON or OFF and makes it ideal for handing large and heavy workpieces easily by one operator offering an improved working condition with increased work efficiency.

Seven Models offer a wide choice of lifting capacities as also the special contoured or V-shaped pole profiles allows the same magnet to be used for lifting round bars or pipes and work pieces.

However, to obtain Maximum magnetic performance and successful magnetic handling, magnet must be placed on thick steel object or workpiece. Care must be taken to see that the surface of the workpiece is flat and there will be no “airgap” between the workpiece and the magnet.

Thin sheets, rough and irregular surfaces, odd shapes and rust can considerably diminish holding power and must be considered in determining a safety factor. The Permanent Magnetic Lifters function best at normal temperatures.

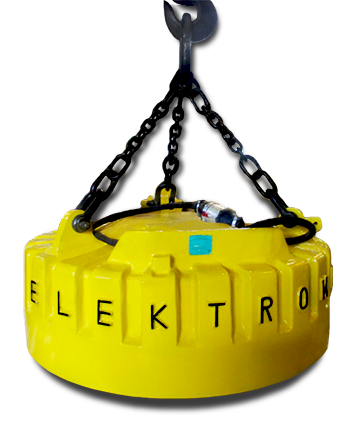

Electro Clinging Magnets

ELEKTROMAG Electro Clinging Magnets are used as an efficient aid for repairing or assembling steel structures or for adjusting and holding of plates to be wielded together without edge.

The housings are made from steel with a high permeability. The excitation coils are made from copper wire and are cast into the housings with an insulation material class H.

On the top of the housing there are two tapped holes for connection purpose as well as two out -leading terminal ends of 250 mm length.

The clinging Magnets work on 24V. DV and are suitable for a 100 % heating up time.

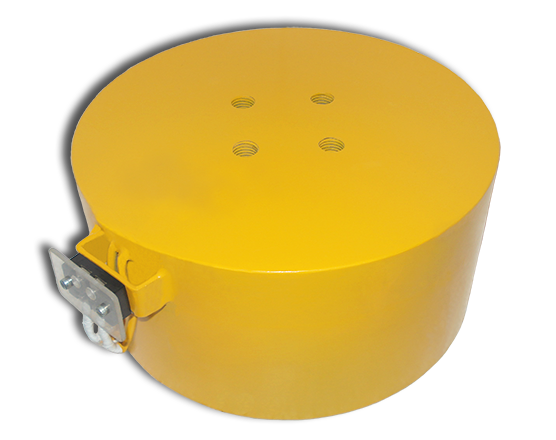

Small Circular Lifting Magnet

Type LR25O-N

The Type LR 250-N is supplied with built-in rectifier and switch and the unit is supplied ready for connection to AC supply with approx. 3 meters long rubber cable and safety plug.

The magnet body is a dynamo steel casting of high permeability. The exciter coil is wound of copper wire and cast into the casting with impregnating and sealing compound of good heat conductivity. Two pairs of suspension plugs, one on the top ,the other at the side permit suspension of the magnet with pole face located either horizontally or vertically.

An integrally cast terminal box at the top encloses the cable terminals, rectifier set in single phase bridge connection and switch.

Type LR25O-N 2

The Type LR 250-N2 has the same dimensions and technical specifications ,but is supplied with separate control unit. The coils are however designed for use with the control unit of Type SLV only.

SEPARATE CONTROL UNIT

TYPE : SLV-4 Dl25O

The control unit is designed with a rectifier set in single phase bridge connection, switch, pilot lamp, fine wire fuse and interruptor (UT).

This control unit is suitable for one to four magnets and all magnets connected to one control unit are switched ON and OFF in common.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.