ELEKTROMAG DEVICES P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELEKTROMAG DEVICES P LTD.

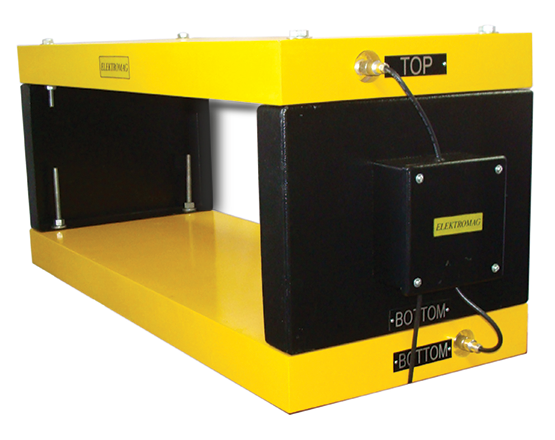

Metal Detectors

Elektromag Metal Detectors are suitable for a wide range of applications in areas where bulk material being transported has to be checked for the presence of metal contamination. Wherever metal pieces in the conveyed material may damage sensitive machinery, the Metal Detector will prevent extensive repairs and production break-down. Typical areas of application include Thermal Power Stations, Steel Plants, Cement Plants, Stone and Earth Industry, Recycling Industry, Slag Processing Industry, etc.

The Metal Detecting Device consists of two components, the PROBE and the AMPLIFIER, both of which are interconnected by one coaxial cable.

The probe will be furnished to match your conveyor belt width. There is a single probe and a tandem probe available. The planar single probe will usually be mounted underneath the conveyor belt.

The tandem probe consists of two planar probes, one of which will be mounted underneath the conveyor belt, while the other probe will be held above the belt by special supports.

The tandem probe is distinguished by a sensitivity that is very uniform over the whole area in between the two planar probes. This probe type is therefore recommended for great charging heights, or if high sensitivity is required. The special supports will be furnished according to your belt charging height.

The amplifier contains the electronic circuitry. The operating controls are on the front plate arranged for easy identification, and are accessible by opening a hinged door.

Actuating the function control button will simulate a metal piece in the conveyed material. This feature allows testing the whole chain of operation of the Metal Detecting Device.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.