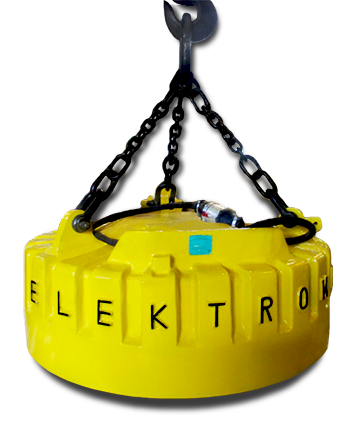

ELEKTROMAG DEVICES P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELEKTROMAG DEVICES P LTD.

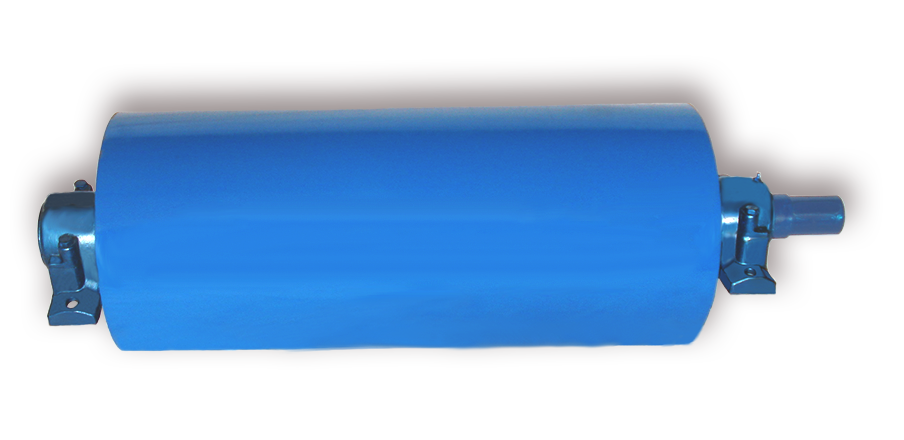

Magnetic Pulley Permanent

ELEKTROMAG Permanent Magnetic Pulleys are powered by ceramic focused-flux, barium-ferrite magnets for superior coercive force.

The Magnetism in a Permanent Magnetic Pulley is produced by an internal assembly of ceramic magnet material and steel. This assembly is enclosed by a flat non-magnetic stainless steel shell that is fastened to cast aluminium heads. The entire pulley is keyed to a solid steel shaft, extending through the width of the pulley and beyond it on both sides. The shaft revolves with the pulley as a single unit. Both heads on the pulley are tapered to allow good belt tracking. The Permanent Magnetic Pulley has a face width that is at least 50 mm greater than the belt width.

The magnetic strength of a Permanent Magnetic Pulley depends on its diameter. Larger diameters are stronger magnetically because they contain more ceramic magnet material. The ELEKTROMAG design concentrates attractive power on the pulley's peripheral surface where it is needed most.

ELEKTROMAG Permanent Magnetic Pulleys are easy to install with sizes to fit every operation from 315 mm to 1250 mm dia. The shafts can be machined to specifications on request.

ADVANTAGES

No-sliprings/carbon brushes to be maintained

No Coils to burn-out

No electric wiring required for pulley

No Power consumption

No operating cost

No maintenance

No failure - hence no downtime

Uniformly powerful

Everlasting magnetic power guaranteed

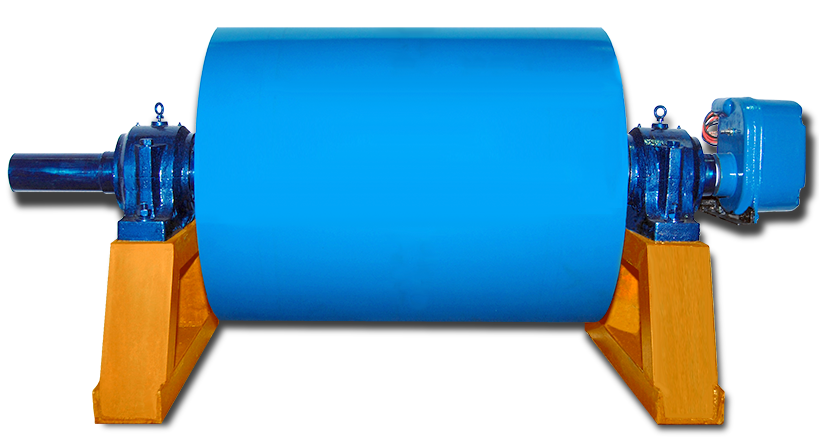

Magnetic Pulley Electromagnetic

ELEKTROMAG Electro Magnetic Pulleys have a magnet system of disk-shaped pole bodies with inserted coils. The pole bodies are made from steel of high permeability. The coils are normally made of Aluminium, rated for class ‘H’ insulation, however, Copper-coils can also be supplied. Pole bodies and coil form a complete unit. All coil connections are led to a terminal box on the face of the outer pole from where they are connected to sliprings through the shaft.

Non-magnetic coil covers are provided between the pole bodies in such a manner that protection against dust and water is guaranteed. The rings made of non-magnetic material at the two outer pole bodies guarantee a good support of the conveyor belt over the entire pulley width.

The electro-magnetic pulleys are placed in two generously dimensioned pedestals with self-aligning ball or roller bearings. The surfaces of the Electro-Magnetic Pulley are turned cylindrically.

D.C. is fed to the Electro-Magnetic Pulleys via two slip rings. The sliding contact device is enclosed in a dustproof housing and contains the necessary carbon brushes.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.