ELEKTROMAG DEVICES P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELEKTROMAG DEVICES P LTD.

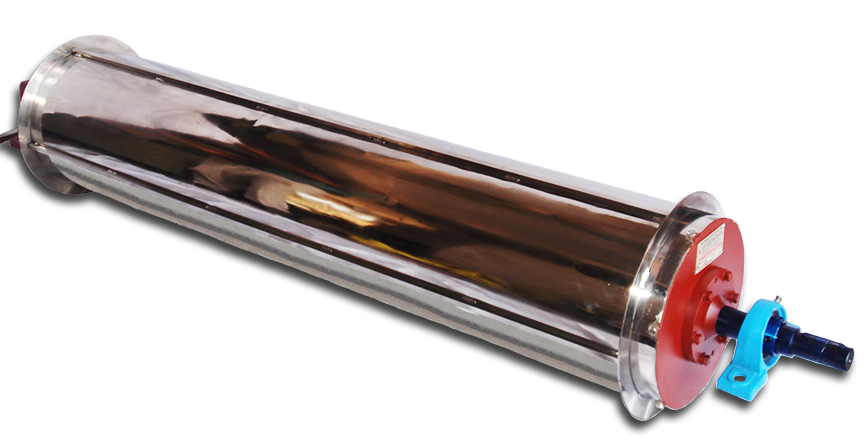

Totally Enclosed Dust Tight Drum Machine

The equipment comes complete with a chute type feed hopper, adjustable feed regulation gate, magnetic drum and geared motor drive in a ready for use condition. Inlet and outlet openings are flanged for ease of connection to customers duct work. Double or Triple Totally Enclosed Machines can also be supplied if required by clients.

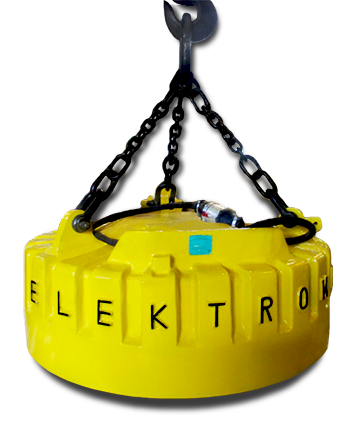

Electromagnetic Drums

Electromagnetic Drums are available in diameters ranging from 800mm diameter up to 1800mm diameter. They are mainly used for heavy duty applications such as slag recycling applications or processing of sheet scrap, mixed scrap from motor car bodies. Depending upon the diameter and the width of the Drums, the magnet support holds multiple steel cores and magnet coils.

The magnetic drum is equipped with a drum shell, made of non-magnetic abrasion resistant steel, with discharge strips and with lateral covers, made of light metal casting, with rotation supports – all these parts rotating around the magnetic system. Ferrous particles contained in the conveyed goods, as far as magnetisable, are attracted by the magnetic system and are discharged at the end of the magnetic system by the discharge strips from the rotating drum jacket.

The rotation supports are equipped with largely dimensioned anti-friction bearings. The mechanical drive is effected via a rotation support designed as driving pin. This driving pin may be equipped with a sprocket wheel or a V-belt pulley.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.