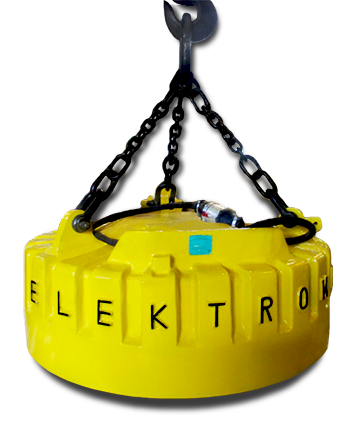

ELEKTROMAG DEVICES P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELEKTROMAG DEVICES P LTD.

Electromagnetic Clutch

'ELEKTROMAG' Electro Magnetic Clutches are used where frequent load cycling takes place. Where a motor must be accelerated and decelerated, there is motor heating which reduces the motor life. By installing a Clutch the motor can be operated at its normal speed and the load can be cycled by engaging and disengaging the clutch.

'ELEKTROMAG' Clutches have been designed for installations where a smooth take-up of drive is essential. Such applications include wire drawing, textile machines, rolling mills, welding plants, machine tools, shearing machine, etc.

[Electromagnetic_Rotor_clutch_2]

ROTOR CLUTCHES 90V. D.C. - Type : RC

‘ELEKTROMAG’ Rotor type Clutches are used in applications where the ATMOSPHERE IS DIRTY and likely to affect the slipring and carbon brushes. These Clutches eliminate the need of carbon brushes as the coil body is stationary and a rotor ratates around the coil body. When the coil is energized the lines of force travel from the coil to the Rotor and the armature plate is attracted to the Rotor and thus engages the drive system.

Following information are required to quote

HP/KW of motor

RPM of motor where clutch is mounted

Shaft dia

Safety factor required

Application for each clutch is required

Operating voltage required (STD 90 VDC)

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.