ELEKTROMAG DEVICES P LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELEKTROMAG DEVICES P LTD.

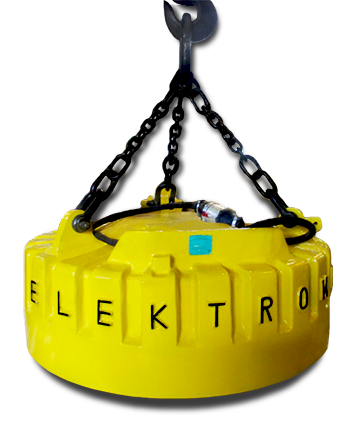

Circular Lifting Magnets Lmr L

Elektromag... Optimum performance with Ionger life

Ever since the company's formation in 1958, Elektromag has championed the task of transporting iron and steel using magnetic power. Based on our past experience of 50 years, our latest lifting magnets are developed. Our circular lifting magnets transport steel blocks, pigs, and scrap in scrap yards and ports and transport and process all forms of scrap in steelworks and foundries. They also crush clinker in skull cracker ball operations.

What distinguishes Elektromag's products from the rest are their quality materials, quality of workmanship and extremely long life. Thousands of Elektromag's Circular Lifting Magnets have been in use for many years throughout the world. We can provide you with specialdesigns and complete solutions. We provide more details of our products and their capabilities in the data overleaf. Take advantage of our expertise.

Elektromag's Circular Lifting Magnets: All our circular lifting magnets are constructed in exactly the same way: in a cast housing, a coilfirmly connected to the housing by means of a heatconductorwhich lies around the central pole. A hard manganese steel bumping plate seals away the magnet's interior. High-performance chains provide maximum safety when carrying the magnet under load. The cable connection is also efficiently protected.

MODEL LMR. L:

The standard duty LMR - L model typically transfers scrap and light scrap with densities of 0.6 to 1 T/M' using mobile cranes. Standard models are available in diameters: 500 to 3200 mm.

Elektromag Circular Lifting Magnets - the difference is the quality

Many Circular lifting magnets tend to resemble one another:

Elektromag magnets outperform the rest in many respects:

The cast housing: This is made from quality cast steel, combining extreme ruggedness with high conductivity.

The Bumping plate: A strong plate cast from hard, wear- resistant, manganese steel protects the coil but does not interfere with the magnetic field.

The coil: This is made from Anodised strip or aluminium /copper conductor. The anodised aluminium strip requires no insulation between turns and has a much better fill factor than copper coils, which increases the load possibilities. The coil is also extremely temperature-resistant.

The heat conduction medium: This insulates the coil from the casing both electrically and mechanically, conducting any heat away outside. lt must also withstand critical temperature spikes without damage. Circular lifting magnets can have operating temperatures of over 200"C in the coil. They must also be able to withstand high pressure during heating. To meet these requirements we use the latest heat conduction materials, specially manufactured to our instructions.

The design: The magnetic pole, the steel cross-section and the flow through the coil have all been precisely tailored to each other to provide optimum transport power and weight conditions.

Accessories

We provide the required power supply for each of our magnets, designed to suit the magnet and your own mains supply. Sets of backup batteries & battery charger to protect against powerfailures that could cause the load to fall. (optional)

We also provide Spring / Sprocket driven cable reeling drums. (optional)

YOU BENEFIT FROM:

The longest operational life: Elektromag lifting magnets have been in use for decades.

Optimum performance and weight conditions: Your existing crane can operate to its maximum capacity, with every load optimised.

Special designs for every application: All our magnets are weatherproof and designed foropen-air use. Magnets can be designed for extreme operating conditions: for instance, Elektromag can supply specially insulated magnets for use in transporting hot material. Based on our experience of installing thousands of Elektromag Circular Lifting Magnets, we can determine and build the precise type of product suitable for your task.

Based on our vast experience we can ensure the best results in every type of application and can produce special designs to suit your requirements.

Complete solutions: We examine your requirements and your operating conditions and then produce a complete solution precisely tailored to your needs with all the components optimally adapted to each other, from the power supply to the magnet itself.

Our experience: We have a lot of practical experience. From processing scrap, right through to skull cracker ball operations, we have supplied equipment for every conceivable requirement.

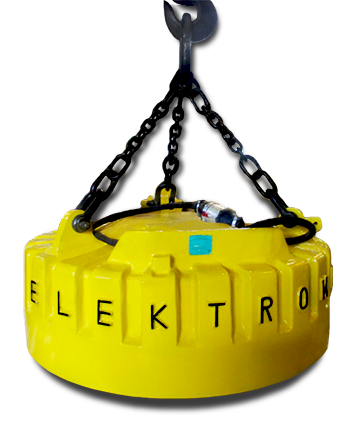

Circular Lifting Magnets Lmr H

The LMR - H models typically transfer scrap and light scrap with densities of 0.6 to 1 T/M' using cranes. These standard models are available in diameters: 700 to 2100 mm.

Elektromag Circular Lifting Magnets - the difference is the quality

Many Circular lifting magnets tend to resemble one another:

Elektromag magnets outperform the rest in many respects:

The cast housing: This is made from quality cast steel, combining extreme ruggedness with high conductivity.

The Bumping plate: A strong plate cast from hard, wear resistant, manganese steel protects the coil but does not interfere with the magnetic field.

The coil: This is made from Anodised strip or aluminium/ copper conductor. The anodised aluminium strip requires no insulation between turns and has a much better fill factor than copper coils, which increases the load possibilities. The coil is also extremely temperature-resistant.

The heat conduction medium: This insulates the coil from the casing both electrically and mechanically, conducting any heat away outside. It must also withstand critical temperature spikes without damage. Circular lifting magnets can have operating temperatures of over 200'C in the coil. They must also be able to withstand high pressure during heating. To meet these requirements we use the latest heat conduction materials, specially manufactured to our instructions.

The design: The magnetic pole, the steel cross-section and the flow through the coil have all been precisely tailored to each other to provide optimum transport power and weight conditions.

Accessories

A) We provide the required power supply for each of our magnets, designed to suit the magnet and your own mains supply. Sets of backup batteries & battery charger to protect against power failures that could cause the load to fall.(optional)

B) We also provide Spring/Sprocket driven cable reeling drums.(optional)

YOU BENEFIT FROM:

The longest operational life: Elektromag lifting magnets have been in use for decades.

Optimum performance and weight conditions: Your existing crane can operate to its maximum capacity, with every load optimised.

Special designs for every application: All our magnets are weatherproof and designed for open-air use. Magnets can be designed for extreme operating conditions: for instance Elektromag can supply specially insulated magnets for use in transporting hot material. Based on our experience of installing thousands of Elektromag Circular Lifting Magnets, we can determine and build the precise type of product suitable for your task.

Based on our vast experience we can ensure the best results in every type of application and can produce special designs to suit your requirements.

Complete solutions: We examine your requirements and your operating conditions and then produce a complete solution precisely tailored to your needs with all the components optimally adapted to each other, from the power supply to the magnet itself.

Our experience: We have a lot of practical experience. From processing scrap, right through to skull cracker ball operations, we have supplied equipment for every conceivable requirement.

Circular Lifting Magnets Lmr.X And Lmr. Xs

The heavy duty LMR - X and extra heavy duty LMR – XS models are used for particularly heavy loads when the requisite heavy duty cranes are available. They transfer compressed scrap with typical densities in excess of 1 T/M3. Although the diameters are the same as for the standard range, they are designed for higher performance. They are therefore heavier and require heavy duty cranes. The XS models are distinguished from the X models by their taller coil, producing an even higher magnetic output.

Elektromag Circular Lifting Magnets - the difference is the quality

Many Circular lifting magnets tend to resemble one another:

Elektromag magnets outperform the rest in many respects:

The cast housing: This is made from quality cast steel, combining extreme ruggedness with high conductivity.

The Bumping plate: A strong plate cast from hard, wear-resistant, manganese steel protects the coil but does not interfere with the magnetic field.

The coil: This is made from Anodised strip or aluminium/copper conductor. The anodised aluminium strip requires no insulation between turns and has a much better fill factor than copper coils, which increases the load possibilities. The coil is also extremely temperature-resistant.

The heat conduction medium: This insulates the coil from the casing both electrically and mechanically, conducting any heat away outside. lt must also withstand critical temperature spikes without damage. Circular lifting magnets can have operating temperatures of over 200'C in the coil. They must also be able to withstand high pressure during heating. To meet these requirements we use the latest heat conduction materials, specially manufactured to our instructions.

The design: The magnetic pole, the steel cross-section and the flow through the coil have all been precisely tailored to each other to provide optimum transport power and weight conditions.

Accessories

We provide the required power supply for each of our magnets, designed to suit the magnet and your own mains supply. Sets of backup batteries & battery charger to protect against power failures that could cause the load to fall. (optional)

We also provide Spring / Sprocket driven cable reeling drums. (optional)

YOU BENEFIT FROM:

The longest operational life: Elektromag lifting magnets have been in use for decades.

Optimum performance and weight conditions: Your existing crane can operate to its maximum capacity, with every load optimised.

Special designs for every application: All our magnets are weatherproof and designed for open-air use. Magnets can be designed for extreme operating conditions: for instance, Elektromag can supply specially insulated magnets for use in transporting hot material. Based on our experience of installing thousands of Elektromag Circular Lifting Magnets, we can determine and build the precise type of product suitable for your task.

Based on our vast experience we can ensure the best results in every type of application and can produce special designs to suit your requirements.

Complete solutions: We examine your requirements and your operating conditions and then produce a complete solution precisely tailored to your needs with all the components optimally adapted to each other from the power supply to the magnet itself.

Our experience: We have a lot of practical experience. From processing scrap, right through to skull cracker ball operations, we have supplied equipment for every conceivable.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.