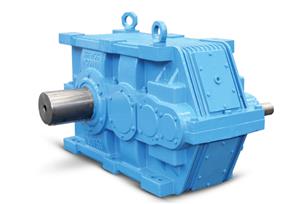

Helical Gear Box

|

|

Planetary Gearboxes have much higher mechanical rating compared to parallel shaft Gearbox as the power being transmitted gets equally distributed among three to five streams in each stage thus reducing the induced stresses which very much optimizes the size as well allows to accommodate higher ratio to eliminate open pair.

The reduction in floor space as compared to conventional drive i.e with open gearing, almost to the tune of 50% reduction in floor space.

Heaviest gear internal such as annuli are stationary thus requires no bearing and automatically improves the stability and reduces the Vibration level and in turn noise. Low noise level of 80-85 db as well as low vibration level going up to 4.5 mm/sec can be achieved.

Direct drive eliminating open gears, bearings for same, coupling in between secondary gearbox and Open gearing – thus saving 5 to 6 % power consumption. For example, for a 45×90 Mill for power 1100 kW which also includes the drive power of TRPF/GRPF we can get a saving which is approximately equivalent to 20% of the additional expenditure for drive-part i.e. within five seasons additional expenditure is recovered and sugar starts earning additional Profit due to this solution.

Planetary Gearbox have an advantage that the planet bearings are only loaded where as in case of Bearings supporting Sun or Carrier loads are more or less nullified by virtue of higher no of planets and their equal and opposite forces.

Lubrication of planetary gearbox is quite simple as the rotating gear train partially act as pump thus allowing splash lubrication.

We are proposing three-to five stage planetary gearbox in each stage Sun is input and carrier is the output keeping annuli stationary as well acting as casing and supported on saddle as shown in Drawing.

Elecon's machine capability cuts the internal teeth of annulus to the accuracy of DIN 7 or Grinds if required to the accuracy class DIN 6.

Planetary Gearboxes have much higher mechanical rating compared to parallel shaft Gearbox as the power being transmitted gets equally distributed among three to five streams in each stage thus reducing the induced stresses which very much optimizes the size as well allows to accommodate higher ratio to eliminate open pair.

The reduction in floor space as compared to conventional drive i.e with open gearing, almost to the tune of 50% reduction in floor space.

Heaviest gear internal such as annuli are stationary thus requires no bearing and automatically improves the stability and reduces the Vibration level and in turn noise. Low noise level of 80-85 db as well as low vibration level going up to 4.5 mm/sec can be achieved.

Direct drive eliminating open gears, bearings for same, coupling in between secondary gearbox and Open gearing – thus saving 5 to 6 % power consumption. For example, for a 45×90 Mill for power 1100 kW which also includes the drive power of TRPF/GRPF we can get a saving which is approximately equivalent to 20% of the additional expenditure for drive-part i.e. within five seasons additional expenditure is recovered and sugar starts earning additional Profit due to this solution.

Planetary Gearbox have an advantage that the planet bearings are only loaded where as in case of Bearings supporting Sun or Carrier loads are more or less nullified by virtue of higher no of planets and their equal and opposite forces.

Lubrication of planetary gearbox is quite simple as the rotating gear train partially act as pump thus allowing splash lubrication.

We are proposing three-to five stage planetary gearbox in each stage Sun is input and carrier is the output keeping annuli stationary as well acting as casing and supported on saddle as shown in Drawing.

|

Elecon Bucket wheel planetary gear units are available in various sizes ranging from 25 to 375 kw and reduction ratio ranging from 140 to 480.

These gear units are especially designed for bucket wheel drive of stacker-reclaimer machines.

The gear unit consists of Four to Five reduction stages comprising of bevel, helical and planetary being a last pair in the system.

The gear units are available in hollow shaft design with Shrink Disc and have a integral drive frame for mounting electric motor and brake, with necessary fork for fixing the torque arm.

The sun, planet and helical wheels are case hardened and ground to quality 6 as per DIN 3961-63. The annulus is made up of high tensile alloy steel, heat treated or nitrided depending upon power requirement. The spiral bevel gears having cyclopalloid tooth from are case hardened and lapped in pairs so as to ensure optimum tooth contact pattern during assembly.

The casing is of welded construction mainly in two parts made out of Fe 410 WA IS 2062. The bearing bores are machined with high degree of accuracy on CNC machines.

Elecon slewing gear units of planetary as well as bevel-helical type (conventional) are available in various sizes ranging from 1.5 kW and reduction ratio ranging from 400 to 1000.

These gear units are especially designed for the slewing mechanism of the stacker-reclaimer machines.

The planetary gear units normally have four-stage reductions out of which the first stage is designed as helical or bevel pair, and the remaining stages according to planetary gear systems.

The conventional gear unit consists of five to six reduction stages comprising bevel and helical gear pairs.

The sun and planet gears are case-hardened and ground to quality 6 as per DIN 3961/63. The annulus is made up of high tensile alloy steel, heat treated or nitrated depending upon power requirement. The spiral bevel gears in case of conventional gear units are case-hardened and lapped in pair so as to ensure optimum tooth contact pattern during assembly. The casing is of welded construction mainly in three parts in case of planetary gear unit and in two parts in case of conventional gear unit. The bearing bores are machined with high degree of accuracy on CNC machines.

Description / Specification of Worm Gear Small

We are involved in offering a wide range of Worm Gear Small to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Worm Gear Small. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

|

Description / Specification of Modular Universal Mounting Gear Box

We are involved in offering a wide range of Modular Universal Mounting Gear Box to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Modular Universal Mounting Gear Box. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Heavy Duty Stirrer unit incorporates an extended bearing housing to accommodate a larger bottom bearing and increased shaft size, there by enhancing the unit capacity to absorb the high bending loads imposed during stirrer applications. This gear unit is compact with facility of top mounted pivoted platform where electricmotor can be directly mounted above the gear unit using belt tensioning device.

Cooling Tower Fan Drive Gear Unit incorporates an extended top bearing housing to accommodate the larger wheel shaft bearing.

Length of the output shaft extension are manufactured to client's requirements and to suit fan hub mounting.

Lubriction is entirely contained by splash and lower bearing dip in the oil bath while oil is pumped to the top wheel shaft bearing by mean of a built in plunger mechanism. All exposed parts other than the extensions are applied with corrossion resistant paint.

|

|

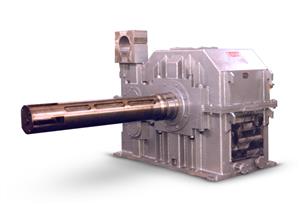

Elecon engineering has expertise in designing and manufacturing high speed, high power gear boxes.

TA – Turbo Gear Unit (Double Helical Gear)

The TA TURBO Gear unit is a single stage step-up or reduction Gear unit with horizontally offset. It is designed as a double helical Gear unit.

High Gearing quality and tooth flank modification adapted to actual tooth load allow for extremely high pitch line velocity.

Double helical Gear units are simple to design & manufacture and compact. Double helical gearboxes are more efficient than single helical gear boxes.

This Gear unit is used in high speed plants such as turbo generators, turbo Compressor, Boiler feed pump application etc.

|

Elecon has started producing Spiral Bevel Gears in 1976. Since then, Elecon using these specially designed, spiral-toothed gears in all Right Angle drive Bevel Helical Gearboxes and also supplying loose Spiral Bevel Pair to various users as per specific requirement.

Today, ELECON have largest capacity and capability to produce such spiral bevel gears in house.

The boggie drive unit consists of double side helical and at the center a worm gear unit which is specified as double Heli-worm gear unit.

The boggie drive arrangement is used where bridge scrapper for lime stone is required to stack and for that this gear boxes are used at two different speeds.

Shunting speed (High speed) – This is achieved through an A.C. Motor which drives worm gear unit through coupling (on RH side).

Reclaiming speed(Low speed) – This is achieved through D.C. Motor which is driven Helical gear box and driving worm gear unit (on LH side).

|

|

|

|

|

|

|

|

|

|

|

Description / Specification of Dual Tandem Gear Box

We are involved in offering a wide range of Dual Tandem Gear Box to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Dual Tandem Gear Box. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

|

|

Elecon has developed as special prupose custom built gear box for Bridle Drive and sheet Mill application. This has two input and two output shafts having independent gear trains driving the output shaft in opposite directions with variation in power input. The output shafts are connected to the rolls which stretch the sheet metal before rolling as well as after rolling.

Teeth of pinion and wheels are of double helical type so as to nullify the axial thrust acting on respective shaft. The gears are made from high tensile carburising alloy steel, 17CrNiMo6 as per DIN-17210 case hardened to 60 ± 2HRC and precisely ground to class of accuracy 6 as per DIN 3961 – 63.

The shafts are supported in Antifriction Spherical Roller Bearings of adepquate size to take care of radial loads permitting large degree of freedom against misalignment.

The gear box is installed with centralised lubrication oil system for providing necessary amount of oil to various gear meshes and bearings thereby resulting into smooth and trouble free operation.

ELECON has successfully designed, manufactured and supplied gearboxes for Coiler – Recoiler Drive for Steel Industries. This gear box will be exported to China through Magadh, Indore. This gearboxes are foot mounted, single stage, parallel shaft, helical gear reducer with solid input and special output shaft (in client scope of supply). This gear box has extra heavy duty Spherical Roller Bearings on output shaft to take care of the dead weight of Coil of 25 Tone as well as Coil Tension.

The gear box housing is made up from extra heavy (Sturdy) Mild Steel Fabricated Material of Fe410 WA as per IS 2062 to take care of the shock load due to coil winding and rewinding.

The internals are case carburised, hardened and ground and specially profile and longitudinal corrected to achieve higher rating and low noise level. The gears are made from high tensile carburising alloy steel of 17CrNiMo6 as per DIN-17210 and case hardened to 60 +/- 2 HRC, precisely ground to accuracy class 6. The toothings and bearings are Forced Oil Lubricated.

Elecon has developed a special purpose custom built gear box type SBN 2 * 570 – 705 S/SO and supplied to M/s. Jindal Seamless Tubes, Nasik for driving 7 Roll Stand Hot Sizing Mill for Stainless Steel, Pipe finishing.

The gear box is basically designed to transmit power from Two * 340 KW, 750 rpm DC Motor with a reduction ratio of 15.95:1. It consists of twin – double reduction stages having two input shafts followed by cluster of 1:1 ratio gear trains resulting into 7 output shafts which are rotating at the same speeds, but having different direction of rotations.

The gears are made from high tensile carburizing alloy steel, 17 CrNiMo6 as per DIN 17210 case hardened to 60 ± 2 HRC and precisely ground to class of accuracy 6 as per DIN 3961 – 63. The output shafts are made from medium Carbon Steel CK 60 N as per DIN 17200 of adequate size to withstand heavy load transmission for better rigidity without undue deflection.

Elecon has already manufactured a smaller in the series, SCF 355/520 for M/s Sponge Iron, Hyderabad and the bigger in the series viz SDN 670/1000 for M/s Essar – Hazira. These are three stage gear boxes having single input and 2 output, driving the briquetting press rolls. Internals of this box is our of 17CrNiMo6 duly case carburized, hardened and precisely ground enhoused on antifriction bearings mounted in fabricated casing.

This gear box is also supplied alongwith a special pair of gear coupling, one of which having facility for adjusting the angular location of the briquetting roll shaft for aligning the cast cavities of the roll liners. The gear box is lubricated by Forced lubrication

The Assel mill reduces and finishes the originally rolled mother tube. The finished seamless pipes are used for the races of antifriction bearings or even for other engineering applications. A tall, gigantic, rugged gearbox, having single input and three output with several idlers, drives this mill. The Assel mill gearbox is 5.1 metres long and 2.7 metres tall, weighing around 23 tons and capable of absorbing strong vibrations and shocks imparted by the tube rolling mill. The open aperture provided in the gearbox allows backward movement of hot working stock.

he piercing mill is used to pierce out and roll the mother tube out of original billet. The single input, double output, two-stage gearbox drives this mill. This is a three metre tall and robust gearbox with a base of 2.8/1.4 meters and weighing around 18 tons.

Technical specifications :

Input power : 1250 kW @ 750 rpm, A.C.motor

Reduction ratio : 5.6875:1

Axial thrust : 1,80,000 N on each output shaft

The gears are made from high tensile carburizing alloy steel, 17 CrNiMo6 as per DIN 17210, case hardened to 60± 2HRc and finely ground to accuracy Class 6 as per the DIN standard to give smooth and trouble free operation. Output shafts are made from medium carbon steel CK 60N as per DIN 17200 of adequate size to withstand heavy load transmission for better rigidity without undue deflection. Gears are integral with shaft/key fitted to shaft and are supported in antifriction spherical roller bearings of adequate size to give higher working life and to correct misalignment. Output shafts are also provided with spherical thrust bearings to tolerate axial thrust load in both the directions. Gears and bearings are housed in accurately machined and highly rigid/robust MS fabricated housing to give better performance

For the growing need of steel roling mills, Elecon has developed custom-made gearboxes to obtain variable speed of rolling mill to suit client’s requirements. Such special-purpose gearboxes have been supplied to Precision Equipments, Flat Products and to ultimate users such as Comet Steels, Sipta Steels, Nanded, and Him Ispat, Himachal Pradesh.

ELECON has successfully designed, manufactured and supplied gearboxes for palm oil industry. This gearboxes are foot mounted, three stage, parallel shaft, helical gear reducer with solid input and out put shaft. The gear box body is out of C.I. and the top gear case has been specially designed to mount electrical motor directly on it. The gear reducer has been fitted with specially designed heavy duty breather plug considering dusty environment.

Elecon has developed and supplied to South Africa; its biggest Bevel Helical Planetary gear boxes, for Slewing and Bucket Wheel drive for a Stacker Reclaimer. These special gear boxes are supplied to M/s Metso Minerals (PTY) LTD. The Stacker Reclaimer is to be used by M/s Portnet, South Africa for handling the Iron Ore at Saldanha Bay, South Africa.

The Slewing drive includes a Bevel Planetary Gear unit, Input torque limiting coupling, Disc Brake, Motor Base frame and Slew pinion.

The Bucket wheel drive includes a Bevel Planetary Gear unit, Input Fluid coupling, Disc Brake, Combined Motor Base frame, flange output shaft with Shrink Disc and Torque arm support.

Bucket Wheel and Slew drive gear box are five stage Bevel Helical Planetary gear unit. The Pinion teeth and wheels are made from high tensile carburising alloy steel, 17CrNiMo6 as per DIN 17210 – Cast hardened to 60 +/- 2 HRC and precisely ground to class of accuracy 6 as per DIN 3961 – 63, except for the Annulus which shall be made out of 42 Cr Mo4, duly Nitrided.

The gear meshes and bearings are splash lubricated for smooth and trouble free operation.

Description / Specification of Spur Gear Wheel

We are involved in offering a wide range of Spur Gear Wheel to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Spur Gear Wheel. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

|

|

|

|