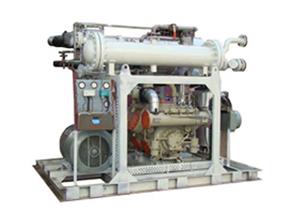

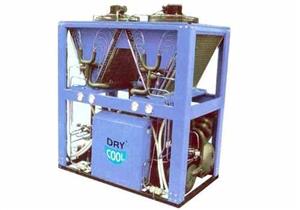

Blown Film Plant Chillers

Blown Film Plant Chillers are required in different industries for direct cooling, ensuring uniform air temperature throughout the processing time. These chillers are highly efficient as compared to the traditional one as these uses flow of chilled air and water chillers for performing their functions. These are integrated with features like direct setting of air temperature, precise temperature control, uniform circulation, reduces power cut and easy maintenance. The high efficiency of these chillers is just because of the premium grade of raw materials used for the fabrication purpose along with latest developed equipments and modern methodology. In addition, these chillers are appreciated among our customers for their rugged design, high efficiency, optimum performance, excellent quality and pocket friendly prices.

23959.jpg)

23961.jpg)

23972.jpg)

23990.jpg)

23991.jpg)