DIGICON MACHINERY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to DIGICON MACHINERY

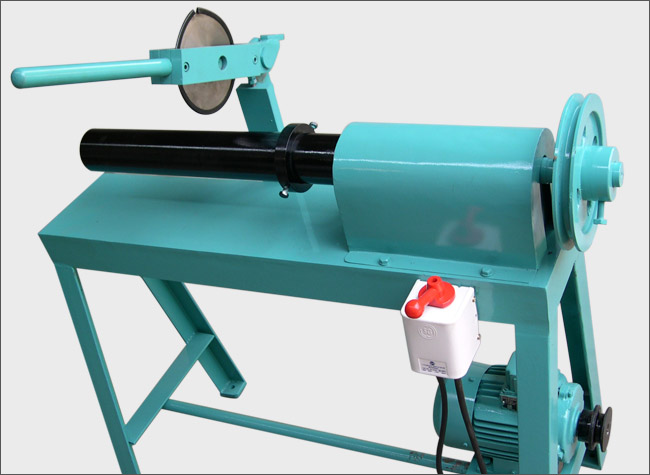

Doctoring Rewinding Machine

Doctoring Rewinding Machine :

Doctoring Rewinding or Winding Rewinding Machines are mainly used to salvadge badly wound roll produced on Slitting Rewinding Machine or to print Mfr. Date, Exp.Date, Batch No, Sr.No. etc. on printed film/foil/paper by using Ink Jet Printing Machine.

Technical Specification :

Web Width - Min. 75mm - Max. 500mm

Reel Dia - Max. 400 mm

Reel Weigth - Max. 100-150 kg

Rewind Core Dia - 76mm (3 Inch)

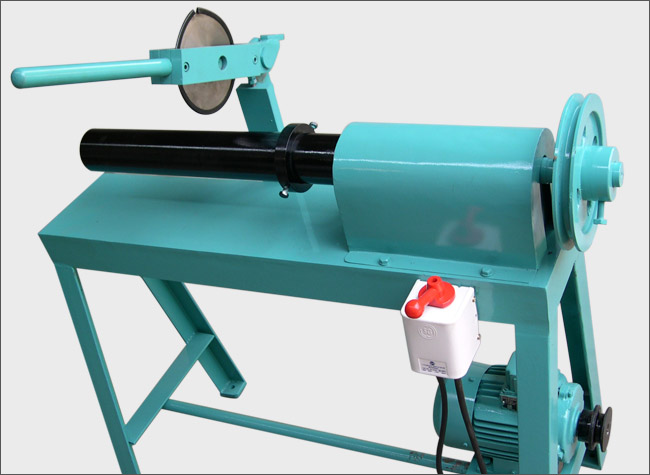

Core Cutter

CORE CUTTER

Processors/Converters are in costant need of different sizes of cores according to their sizes of slitted or printed materials.

Core cutter is most suitable machine to serve the purpose.

We offers -

Manual Single Blade core cutter

Semi Automatic Multi Blade core cutter

Features :

Compact design and easily movable

Safety guards for cutter & movable parts

Maintenance free & hassel free, easy operated,perfect edge cuts

Slitter Rewinder Machine

The most advanced technologically duplex cantilevered Slitter Rewinding Machine for the Converting Industry.

Our innovative and unique rewind technology, including roll lock.

Differential Air shaft and accurate weight counter lay-on roller system, deliver the ability to rewind even the most difficult light gauge film and complex Lamina

Cantilevered Features

Touch control screen interface.

Auto roll lock differential air shaft.

PLC controlled

Laser core position.

Database files management for repeatability.

Shaft less unwind with combo tapper core 3” & 6”.

Hydraulic reel Lifting System

Pulverizer Machine

Application :

Digicon Make Pulveriser is designed for pulverizing of semi-rigid, brittle and impact resistance materials where a powdered product is required.

Granulated Plastic materials are fed via vibratory feeder into the Mill.

High speed Mill grinds the materials and suction system draw the materials from mill.

With the help of proper metering and various screening system desired powder quality to be achieved.

Coarse materials from the screen are re-entering into the mill via closed-loop system.

Typical applications are the pulverizing of LDPE,LLDPE, HDPE,UPVC,RPVC, PC and various other plastics.

Scrap Grinder Machine

Description / Specification of Scrap Grinder Machine

We are involved in offering a wide range of Scrap Grinder Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Scrap Grinder Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.