Products & Services

Poultry Processing Plants

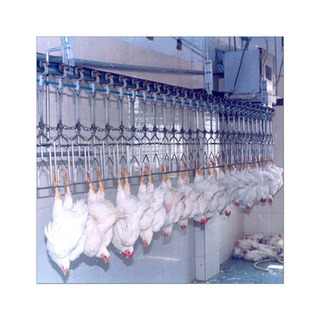

Poultry Processing Plants are Conveyor - based chicken slaughter plants having an overhead conveyor and full range of process machines. The birds are dressed on the conveyor through all the important stages of processing such as stunning, halal, hot water scalding, de-feathering, evisceration & chilling etc. The conveyor based operations are scientifically designed machines ensuring the highest levels of hygiene providing the best quality of meat. They are designed for dressing capacities of 250 to 2000 Birds Per Hour (BPH).

Waste Rendering Plants

Our Rendering Plants For Poultry include a Digestor-Cooker-Homogeniser unit to cook and sterilize the waste. It is supplied with a sophisticated barometric spray system to scrub all the foul smelling gases released during the cooking of the chicken waste. Poultry waste rendering plants are indispensable in any Poultry dressing operation. They render and convert all the non-edible Poultry waste parts into a sterilized meat meal.

Chemical Process Plants

We supply Chemical Processing Plants. These plants are completely integrated to give the best quality of product. These include:

Stable Grade Bleaching Powder Plants and

Cardanol Resin Plant (Based On CNSl - Cashew Nut Shell Liquid)

These are available in different capacities and reputed for efficient & safe operations.

Process Equipment

Our range of Process Equipment covers:

Distillery Blenders

Double Cone Blenders

Double cone vacuum driers

Stainless Steel Tanks

Screw Conveyors

Aluminum Tanks, etc.

These are fabricated as per client specifications by adopting advanced TIG and MIG welding technology. They are perfectly engineered to ensure optimum efficiency & reliability of operations even in the most demanding conditions.