DHARA PETROCHEMICALS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to DHARA PETROCHEMICALS P.LTD.

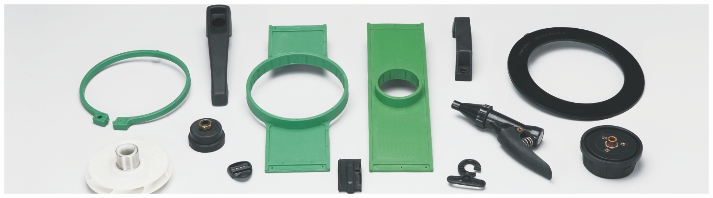

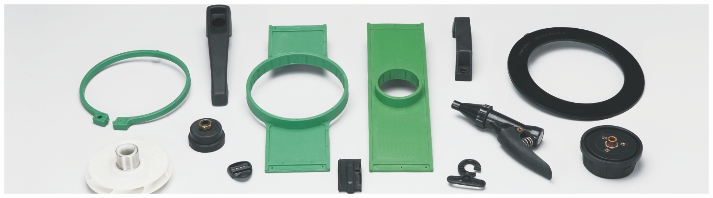

Dpnor

Dpnor modified PPE is a strong engineering plastic with outstanding mechanical, thermal, and electrical properties. Low moisture absorption and low thermal expansion make Dpnor one of the most dimenssionally stable thermoplastics available. Dpnor is widely used for water portable parts, electrical housings and structural components since it has excellent insulating properties, flame resistance, and dimensional stability over a wide range of service temperatures. Dpnor is often selected for fluid handling applications since it has low moisture absorption and excellent strength and stiffness. Dpnor is easy to fabricate, paint, and glue.

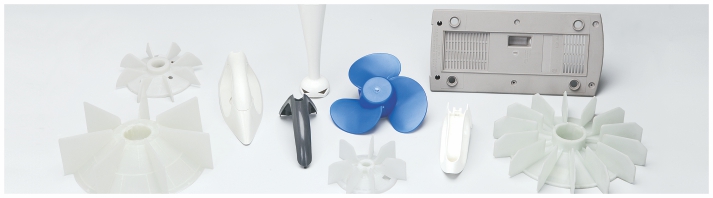

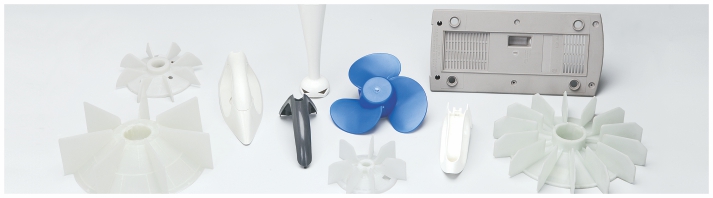

Dplen

Dplen Polybutylene Terephthalate is a semi crystalline Thermoplastic engineering polymer having application in Electrical & Electronics industry as an insulator. PBT is resistant to solvents & a type of Polyester shrinks very little during forming, is mechanically strong, heat resistant up to 150 or 200 degree with glass fiber reinforcement and can be treated with flame retardants to make it noncombustible.

Dpron

Dpron Polypropylene Compounds has the advantages of excellent comprehensive properties, good chemical stability, good shape processing performance and relatively low cost. It is adapted to a wider range of application requirements through modifying, copolymerization, grafting, blending, reinforced filling, Glass filling etc.

Utility Compounds

Plastic Industry in India is growing at 14 to 15 % per annum including domestic as well as industrial polymers. It is boon as well as curse in terms of disposal, as in last five years India has came across many new high end engineering polymers at the same time awareness has also spread across the globe regarding global warming and plastics disposal in friendly manner with out harming the environment.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.