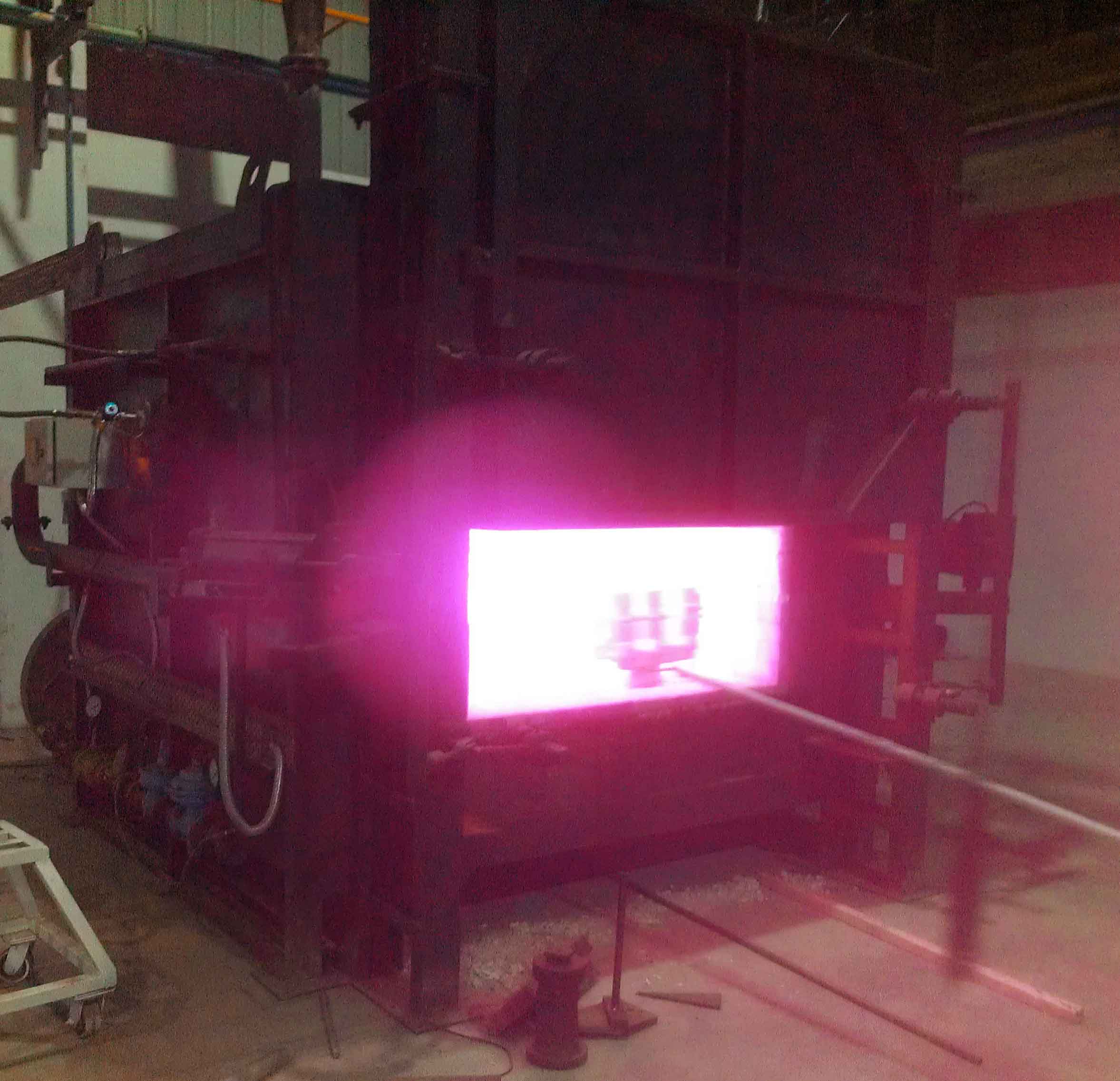

Defoaming Furnace

Defoaming Furnace for Lost Foam Mould Sintering

Thermocol patterns are used to make ceramic mould by slurry process. moulds are dried in an oven for two hours for removal of moisture.

The molds are subjected to sudden heating at 10500 C in defoaming furnace which give rise toxic smoke fumes. Moulds are heated for one hour. The fumes pass through after burner chamber – recuperator, cooled with water in quencher, passed through Ventury Scrubber, Demister, sucked by ID fan and vented off through chimney meeting national ambient quality norms. All automatically done by PLC, HMI, SCADA.