CYBERNETIK TECHNOLOGIES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CYBERNETIK TECHNOLOGIES P.LTD.

Microbrewery

With a passion for brewing, our team has designed and built a state of the art, automatic microbrewery that can be installed in pubs, restaurants and clubs. Since 2012, we have installed breweries ranging in capacity from 150 liters to 500 liters.

Main features:

- Complete Stainless steel 304 mirror finish.

- On-board computer to monitor temperature curves and control motors drives and heaters through optimized PID control.

- Easy to use SCADA and HMI systems

- Integrated CIP systems and optimally designed vessels for complete cleaning.

Advantages:

- Fully automatic system with built in recipe storage system

- No brew master required

- Reduced energy costs with a total power consumption of 30kW

- Optimized footprint and elegant design

- Plug and play system that can be installed in 2 days.

We have a pilot brewery available for testing and brewing your own beer before you order your own!

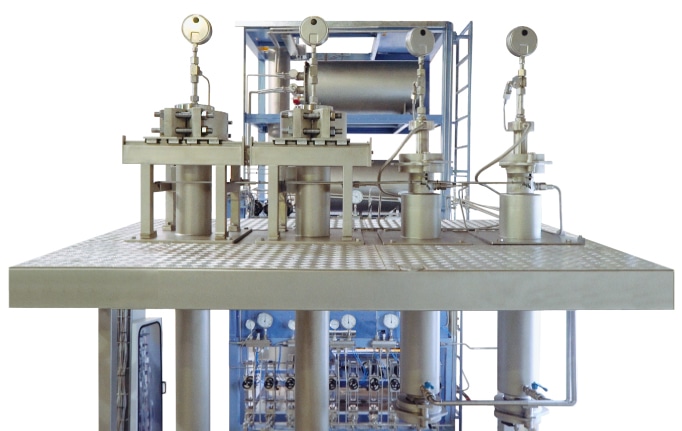

Hops Extraction System

To make the brewing process more efficient, improve brew quality and reduce cleaning time that’s wasted in cleaning out spent hops, we have developed a super critical fluid extraction system for extracting and preserving alpha acids and hop oils in a concentrated form.

These hops extracts can be used like original hops but come with added advantages like:

- They require lesser storage space than hops,

- They have a longer shelf life,

- Extracts ensure preservation of essential bittering and aroma components

The SCFE systems built by Cybernetik have been installed extensively in USA for hops extraction. Our systems are easy to use and maintain, come equipped with an on-board computer for continuous monitoring and control and ensure highest safety standards for usage.

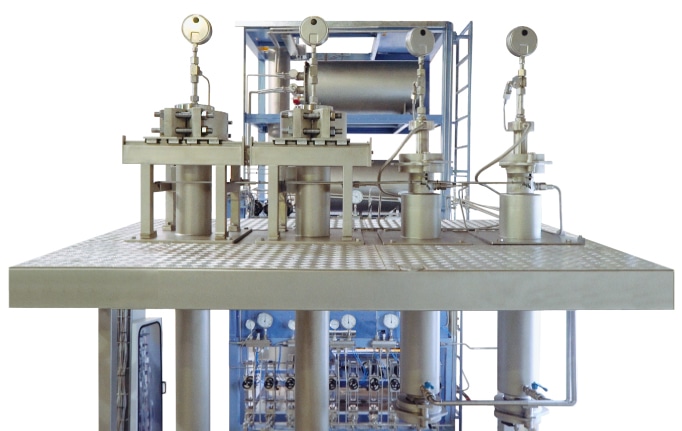

Distillery

Cybernetik offers a range of research distilleries for generation of high purity ethanol. Our distilleries are a result of our deep research in ensuring process integrity and ease of use for the end users. The distilleries consist of two column stills with analyzer and rectification sections, coupled with molecular sieve columns for generation of fuel grade ethanol.

The research distilleries are ideally suited for educational and research institutions.

- The capacities range from 1hL to 10hL

- They include a user-friendly SCADA system for continuous process monitoring and control

- All equipment is built adhering to highest manufacturing standards for hygiene and quality

The distillery is offered with mashing-saccharification vessels, agitated fermenters and support vessels for storage.

Automatic Bag Slitter

- These stations are used for heavy duty bag emptying. Station is equiped with circular saw for cutting bags in two halves and then powder from cut bags is emptied in sifter below.

This station can handle up to 120 bags per hour. Paper shreds and bag halves are manually removed.

Negative draught port ensures that entire operation is dust free.

Big Bag Unloading System

- Cybernetik Offers range of Big Bag Unloading Systems to accept 200 to 1000 kg bags. Unique docking head connects bag spout to downstream equipment for dust free transfer of powders from bag. Four heavy duty massaging arms help remove settled powder from bags without damage.

System is offered in carbon steel and SS304 construction for use in Chemical, Food pharmaceutical applications.

Loss in weight feature is offered as an add-on and helps meter out powders for precision dosing. -

Additional features includes:-

- Optional on-line sifting,

- On-line lump breaker and

- Pneumatic conveying.

Bag Emptying Station With Sifter

- This station can help unload powders from bags with minimal spillage and dusting. This station is equipped with negative draught port which sucks in dust clouds as you empty powders from bag/ container.

Powder is then sifted on line for removal of paper shreads, threads and other packing material

This powder can then be directly transferred to containers or conveyed to other location using powder charging system.

Drum Containment System

- Cybernetik Technologies manufactures drum containment systems that are used to transfer powder from a drum with a liner into a reactor with minimum operator exposure to the product.

- The drum with a liner is loaded onto the drum containment system and its spout is engaged in the liner clamping system. Once the liner is secure and clamped, the operator lowers the lance into the drum. The lance is balanced by a counterweight system for ease of movement of lance. The powder is then sucked out of the drum. Since the drum is not clamped, access to the liner as well as the bottom of the liner is possible. Air bleeds into the unit through a filter. A DP gauge is offered to monitor the filter status. The system is uncomplicated, easy to assemble & dismantle.

Pneumatic Drum Tilter

- Cybernetik Technologies manufactures pneumatically operated drum tilters to unload material from a drum into a hopper or reactor. The drum tilter consists of lifting & tilting cylinders, a drum holder, an extension piece (Hopper), hand operated valves and an air service unit.

- The hand operated valves are used to operate the pneumatic cylinders for lifting and for tilting. When the tilting cylinders are operated, the entire drum holder assembly tilts. Flow control valves are provided to adjust the speed of the lifting and tilting cylinders.

Pan Feeders

Description / Specification of Pan Feeders

We are involved in offering a wide range of Pan Feeders to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Pan Feeders. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Rotary Arm Discharger

- The rotary arm discharger is a vacuum duty unit driven by a 180 degree pneumatic actuator. This unit is used to agitate the product to assist in the discharging operation. The product from the discharger is conveyed to the next process by means of a Powder conveying system (PCS).

Intermediate Bulk Carrier (Ibc)

71147.jpg)

- Cybernetik Technologies manufactures a special type of IBC designed for application in the pharmaceutical industry. It has a top lid to allow the operator to fill material in it. A wafer valve is fitted below the IBC to allow the operator to discharge the material manually from IBC. This IBC can be provided with locating lugs to suit the lifting arm. The top lid is provided with gaskets to ensure less leakage. The IBC can also be made on a castor mounted trolley to enable easier mobility.

Ibc Column Lifts

- The IBC column lift is used to lift an intermediate bulk carrier (IBC) and place it in a desired position. This custom-built system is very easy to operate and maintain.

- This system typically consists of the following components:

- IBC

- Outlet valve

- An electrically or hydraulically operated column lift.

- A motor driven gearbox, lifting belt and pulley system to carry the load of the IBC.

- A control panel comprising of pushbuttons to control the motion of the IBC, and

- Sensors, to monitor the position of the IBC.

Dense Phase Vacuum Conveying System

- The Dense Phase Vacuum Conveying system from Cybernetik is used for powder charging in pharmaceutical, chemical, and food industries. It can charge powders from drums/ sacks to silos/ reactors at rates exceeding 4000 kg/hr and over 25 meters.

- The PCS from Cybernetik has the following advantages:

- Easy to use.

- Easy to wash. You can dismantle the whole system in less than 3 minutes for washing. No bulky valves/ electrical parts that need to be dismantled. All controls are mounted in a convenient Starter box.

- Easy to replace PTFE cartridges for filtration.

- Optional HMI for multi product setups.

- CIP/ SIP options possible.

- High Technology powder conveying in one simple package.

Mobile Powder Pump

The High Mobility Powder Pump from Cybernetik can charge powders from drums/ sacks to silos/ reactors at rates exceeding 400 kg/hr and over 10 meters.

It has the following advantages:

- Easy to use.

- Easy to wash. You can dismantle the whole system in less than 3 minutes for washing. No bulky valves/ electrical parts need to be dismantled. All controls are mounted in convenient Starter box. Easy to replace PTFE cartridges for filtration.

- Optional HMI for multi product setups.

- CIP/ SIP options possible.

- High Technology Powder Pump in one simple package.

Tiptrak Bucket Elevator

- The TipTrak Bucket Elevator from Cybernetik is capable of running both horizontally and vertically, or at any angle in between using a single drive. The plastic buckets are interlocking and never separate. The heart of the TipTrak design is the patented TipTrak chain. This is moulded with an elastomer around it and bonded to a core of multiple strands of stainless steel aircraft cable. Similar to a timing belt in design, it has positive drive. With the stainless steel cable core (which is pre-stressed at the time of moulding to eliminate elongation), the TipTrak drive belt combines all the advantages of a chain, i.e strength and positive drive, with the benefits of a belt such as having no moving parts, corrosion resistance and a long life.

This unique design eliminates the need for sprockets except at the drive end. At all other points the chain runs in a flanged pulley, much like a V-belt in a sheave.

These design features deliver important advantages. By running horizontally and vertically without transfer points, your product can move from one process to another without spillage, degradation, dusting or segregation of blended products.

The interlocking buckets ensure that there is no spillage at the infeed and because the buckets never separate, even on vertical lift, the only place your product leaves the buckets are at the discharge. Even here the TipTrak design allows for a gentle cascading of product, further reducing degradation.

The TipTrak chain, through its unique combination of design and materials, delivers trouble free operation, year after year, even in the most demanding industrial environment. There are no roller chains to stretch or bushings to wear out. In fact, there are no moving parts in the TipTrak chain. The chain runs slack and, after the initial setup, never needs adjusting. Non-metallic construction makes the TipTrak ideal for situations requiring sanitary or corrosion resistant materials. This feature also means that conveyors are quiet. In short, the unique TipTrak construction means the gentlest handling, the least spillage, the lowest possible maintenance, and the quietest operation of any mechanical elevating device.

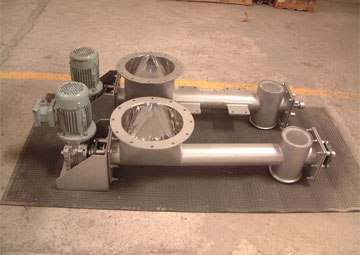

Screw Conveyor

- Cybernetik Technologies has proven its expertise in manufacturing different types of screw conveyors for the powder handling industry. They can have multiple inlets and outlets and their conveying rate is dependent on the pitch and the rotational speed. The screw conveyors can be fabricated in different materials depending on the type of application. They can convey free flowing powder in the horizontal or vertical directions. Cybernetik has manufactured screw conveyors with maximum lengths of 40 meters and maximum conveying rate of 10 tonne/hour.

- For more information, contact

Roller Conveyors

Description / Specification of Roller Conveyors

We are involved in offering a wide range of Roller Conveyors to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Roller Conveyors. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Powder Flight Conveyor

- Powder flight conveyor is a powder transporting device, consisting of a constant-diameter tube containing a series of discs mounted at fixed intervals on a cable—with a drive mechanism that propels the discs through the tube at a velocity sufficient to cause turbulence within the tube.

The Powder flight conveyor consists of a continuous cable-and-disc assembly, contained within two parallel tubes held by a terminal housing at each end. The cable assembly is mounted on terminal sprockets within the housings, and one of these sprockets drives the conveyor. The discs are not a close fit in the tubes. Typically the radial clearance between disc and tube wall will be 3 to 6 mm. One end of the conveyor (usually the discharge end) will incorporate a tension adjustment device for taking up slack in the cable when it becomes extended through use.

Liquid Drum Evacuation System

- The system consists of an MS – PU painted enclosure. The enclosure will have door at the back & glass panels on the front & the sides. The front side of the enclosure will have a sight glass & a pair of hand gloves. The enclosure will have a drum-locating fixture having split idler rollers & an arrangement for rotating the drums. The enclosure will have a suction port for connection to the plant scrubber system.

The booth will have an idler roller conveyor at the loading end with a pneumatic cylinder connected with drum clamping fixture for lifting the drum from the pallet to the loading conveyor. - Drum Evacuation System consists of the following Specification:

- FRP coated MS PU painted Cabin with door, door sensor, sight glass & hand gloves.

- Drum tilting fixture with foot switch operated pneumatic bellow & split idler rollers.

- Rodless pneumatic cylinder assembly with FLP solenoid valve, suction pipe, obstruction sensor, drip scoop & bung hole guide plate.

- Loading idler roller conveyor with filled drum lifting pneumatic cylinder, drum-clamping fixture, cross trolley & supporting structure.

- Control panel housing the PLC to be located in the flameproof area.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.