CYBERNETIK TECHNOLOGIES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CYBERNETIK TECHNOLOGIES P.LTD.

Tobacco Handling And Processing

- Tobacco cleaning lines to include feeding/picking conveyors, trommels

- Tobacco threshing lines to include conditioners, threshers, lamina and stem classifiers , gyro-sifters etc

- Tobacco processing and flavoring lines to include blenders, flavor preparation systems ( casing kitchens), bagging stations etc

- Tobacco roasting plants

Starch Processing Plants

Cybernetik Technologies has more than 20 years of experience in manufacturing high end pharmaceutical grade equipment. Starch powder is produced by milling of corn, maize and other agro based products. Our starch processing systems are used to sterilize this starch powder to make it usable in the pharmaceutical industry. The heart of this system is the paddle-type sterilizer and cooler, which ensures removal of all bacteria and makes the starch usable in the pharmaceutical industry.

- They are highly efficient, mechanically agitated, indirect heat transfer devices that add or remove heat from a process mass.

- They are used for drying, heating, cooling, pasteurization, crystallizing, and reacting of pastes, cakes, powders, and granules.

- Dual counter-rotating shafts with unique intermeshing wedge shape paddles produce intimate mixing and optimize heat transfer.

- The use of hollow paddles for heat transfer results in a compact machine.

- The heat transfer medium: steam, oil, thermal fluid, water, or glycol is isolated from the process mass.

- Vapor tight designs for applications with volatile organic compounds (VOCs) or hazardous materials.

- Temperature sensitive materials can be dried at low temperatures under vacuum.

- Maximum capacity of 4 ton/hour

- Storage silos

- Screw conveyors for powder conveying

- Dense phase pneumatic conveyors

- Turbo sifters to achieve pharma grade powder size

- Metal detectors for removing any contamination

- Automatic bagging machines with integrated sealing, printing, weighing and rejection stations

- Robotic palletising systems with automatic pallet loading

The resultant sterilized starch powder has many applications, such as:

- Maize starch is used as a base in the preparation of vitamin-C antibiotics, filler in pills & capsules.

- Corn Starch & Glucose are used as filler in pills & capsules.

- Starch & Glucose are used to coat bitter tasting pills.

- IP/BP ( pharmaceutical) grade maize starch is useful as a tablet binder and disintegrating agent in dispersible tablets

All our systems can be monitored through user-friendly SCADA systems and can be integrated with up-stream and down-stream existing systems. These systems are built in Stainless steel 316 and are manufactured under hygienic conditions.

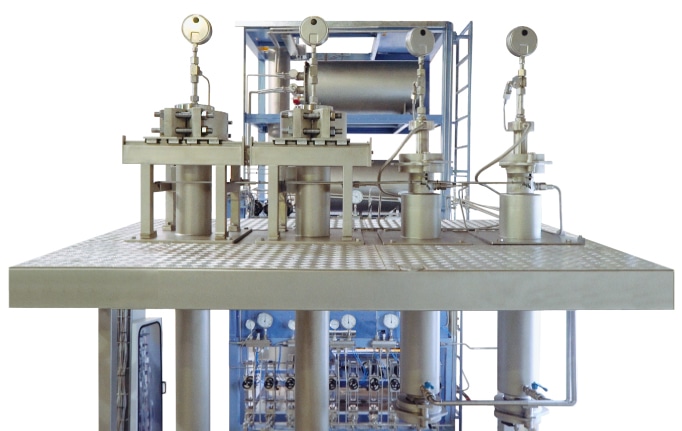

Critical Fluid Extraction

Cybernetik has developed a state of the art supercritical fluid extraction system that can help increase extraction efficiency and yield of oils and oleoresins, in comparison to traditional extraction techniques. The system can be used for extraction from herbs and spices such as oregano, hops, turmeric etc.

When carbon dioxide is compressed and heated to a certain pressure and temperature, it is referred to as a supercritical fluid. In this state, carbon dioxide exhibits solvating properties of a liquid and the diffusivity of a gas. This makes it a powerful medium for extraction of natural oils from organic materials.

The system consists of a high pressure system ranging from 300 to 600 bar with high end pumping technology, extraction vessels, gas-liquid separation chambers and complex pressure regulating valves. All these equipment are controlled and monitored through a user-friendly HMI and SCADA system.

The benefits of using SCFE systems by Cybernetik include:

- Higher extraction efficiency

- FDA approved process due to use of carbon dioxide as a separation medium

- High product purity

- Negligible decomposition and damage of extracted oils due to mild processing temperatures

- Easy to clean and maintain. Different oils can be extracted from the same system.

- Lower operational costs due to reusability of the carbon dioxide

Cybernetik offers fully automatic as well as semi-automatic systems, based on the production scale of the user.

Capacities available:

- 5 liters

- 25 liters

- 100 liters

(capacities indicate the volume of the extraction vessel, i.e volume of the natural product that oils will be extracted from)

Applications:

- Decaffeinating of coffee and tea

- Extraction of essential oils and oleoresins

- Extraction of flavors from natural resources

- Extraction of ingredients from spices and red peppers

- Extraction of fat from food products

- Fractionation of polymeric materials

Industrial Mixers

- Stainless steel 304/ 316 sanitary construction

- Ergonomic design

- Easy to clean and maintain

- Modular in nature and can be integrated seamlessly with upstream and downstream equipment

- Intermediate bulk carrier blenders

- Sigma mixers

- Ribbon blenders

- Continuous mixers

- Plough share and twin plough share mixers

- Powder conveying systems

- Granulating, WDG systems

- Automatic bagging machines

- Robotic handling systems

Spice Processing And Handling Equipments

- Pounding mills

- Intermediate bulk carriers (IBC)

- IBC Blenders

- Infrared dryers

- Spice conveying systems

- Spice roasting plants

Bag And Drum Handling Equipments

Cybernetik Technologies manufactures different types of bag and drum handling systems for the food industry. Using food grade materials, sophisticated controls and user friendly human machine interfaces, we build modular systems that can be either seamlessly integrated into existing systems or be part of complete turnkey lines.

Our bag and drum handling systems include both receiving feeding systems as well as end of line systems.

Our equipment is manufactured as per food industry standards and have following key features:

- Design and manufacturing as per CGMP standards

- Stainless steel 304 and 316 sanitary and food grade construction

- Sophisticated controls with distributed drives

- Ergonomic design

- Easy to clean and maintain

Our modular systems include:

- Big bag loading and unloading systems

- Small bag dump stations

- Bag slitting machines for dust free powder removal

- Drum tilting stations

- Drum evacuation systems

As all our systems are modular, they can be integrated upstream and downstream with other handling and processing equipment such as:

- Food grade mixers

- Food conveying solutions

- Food storage solutions

- Robotic palletising and depalletising systems

Robotic Palletiser

- Bags and sacks

- Drums

- Pails

- Boxes and Cartons

- Modular design that can be customized according to plant layout

- Use of servo or pneumatic end of arm grippers for high speed applications

- Ability to handle variations in products through use of 2D/3D vision systems

- Automatic end of arm tool changing to provide flexibility in operations

- Customized, easy to use HMI and SCADA system for system monitoring

- Easy integration with upstream and downstream equipment

- Complete documentation, training and 1 year system guarantee

- Automatic bagging and drum filling machines

- Stretch wrapping machines

Stretch Wrapping Machine

- Completely Inline.

- The geometry and position of the carton is unchanged.

- Requires minimal floor space.

- Wi-Fi equipped.

- Smart operator interface

- Seamless integration with upstream robotic palletizing systems, pick and place systems and conveyors

Automatic Bagging Systems

- Automated bag filling and closing operation

- Multiple bag stacking and presenting system

- Loss-in-weight feeding for accurate powder filling

- Inline bag stitching, printing, labelling, weighing and bag conditioning operations

- Handles a wide range of bag sizes and types

- Range of filling capacities

- Stainless steel construction

- Compliance with EU/US hygiene standards like USFDA and EHEDG

- Compliance with EU/US manufacturing standards like CE and CGMP regulations

- Seamless integration with other existing equipment in the plant

- Modular link plastic belt to all conveyors

- Ease of operation and maintenance

- User friendly HMI

- Optional connectivity to remote SCADA systems

- Interfacing with palletising systems

- Fully integrated control and operation

- Powder sampling

- CIP cleaning

- Hazardous area compliance

Sludge Dewatering Systems

- Maintenance free operation

- Complete stainless steel design to prevent corrosion

- Integrated safety using vibration sensors and safety controls

- User friendly HMI

Tire Recycling Plants

Cybernetik has built and installed systems used in tire recycling and rubber recycling industries. We have built conveying, sifting, and bagging systems. Recycling of tire is an important sector whose problems we address as the recycling of urban waste is going to be critical for a sustainable future.

Our systems include:

Conveying Equipment

- Tumble back feeders

- Belt conveyors

- Screw conveyors

Screening Systems

- Vibratory sifters

- Trommels

Bagging Systems

- Automatic bagging machines

- Semi-automatic bagging machines.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.