COSMO FILMS LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to COSMO FILMS LTD.

Printing And Pouching Films

Our printing & pouching films are used in the packaging of snack foods, bakery products, ice creams, fresh foods, chocolates and confectionery, etc.

We offer superior performance films supporting high quality printing & converting. The films could be used either as a monoweb or as a laminate on horizontal form fill seal (HFFS) and vertical form fill seal (VFFS) packaging machines.

Barrier Films

Our focus on our customers’ needs led to the development of our range of barrier films. These Barrier films provide solutions for two of the biggest challenges the packaging film industry is facing:

[a] reducing food wastage through enhanced shelf life of food products, and;

[b] reducing packaging material consumption through laminate rationalization

Our range of moisture,

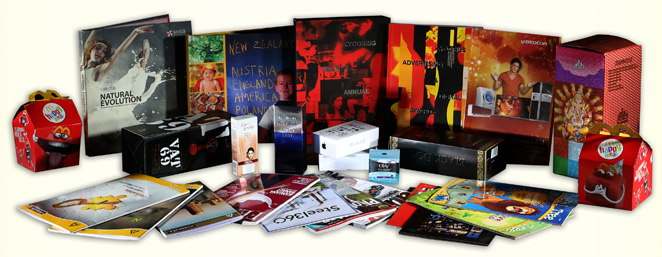

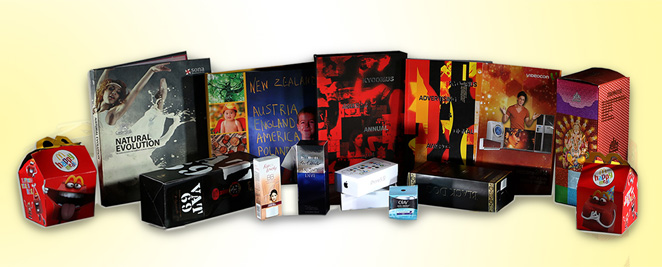

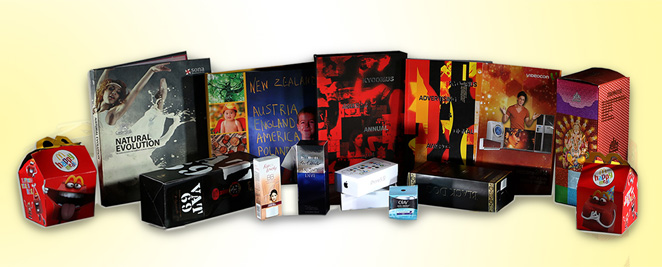

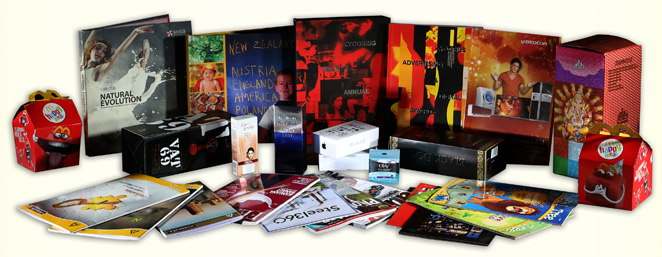

Lamination Films Standard Range

Thermal lamination films have extrusion coated surface with low temperature melting resin, which enables the lamination of film to paper products by heat and pressure. Our films can be used on all types of thermal laminating machines available across the world. We provide thermal lamination films in both BOPP and PET base. On the other hand, wet lamination films are suitable for conventional wet lamination done with dispersion, solvent-based, UV or special hot-melt adhesives. All lamination films used for wet lamination are pre-treated on both sides for subsequent converting (hot stamping, embossing, UV spot varnishing, etc.). The films are slip modified for high speed lamination and have good anti-static properties. The films also have excellent adhesive anchorage which in turn supports excellent bonding with paper. These films are available in BOPP base.

Lamination Films Special Applications

Description / Specification of Lamination Films Special Applications

We are involved in offering a wide range of Lamination Films Special Applications to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Lamination Films Special Applications. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Label Face Stock Films

Majority of the home care & personal care products around the globe use our label stock films for their self-adhesive label needs. Our films also find usage in imparting functional and aesthetic appeal in beverage and pharmaceutical products. All the films meant for label face stock are Universal Printable films; which means that they can deliver superior print performance across diverse printing processes which include UV, flexography, gravure, letterpress and offset. The films are also compatible with all ink based systems, i.e., UV, water based and solvent.

In Mould Label Iml Films

In Mould labels are getting increasingly popular due to good aesthetics, durability of the label and the elimination of an additional step of labelling the container. Our current portfolio consists of white films with good anti-static and orange peel effect. Transparent films are under development.

Direct Thermal Printable Dtp Films

Direct Thermal Printable Films are BOPP films with a proprietary coating which enables image/impression formation on the film upon contact with the print head of the thermal printer. A protective layer is generally applied to protect the coated surface from mechanical abrasion, climatic factors, chemical products etc. The film thus offers good scuff & water resistance. The film also lends an excellent paper like matte finish and produces a dark image on printing while consuming limited energy during the printing process. It is used for a multitude of applications like information labelling (airport baggage tags), manufacturing to retail tracking, POS weight and price labelling, etc.

Adhesive Tape Films

We offer non heat sealable transparent films for pressure sensitive tapes in range of 21-40 microns. Films are generally offered with one side treated surface for enabling adhesive anchorage with water, solvent and acrylic based PS adhesives. The films offer excellent flatness, gloss and clarity.

Textile Bag Films

We offer non heat sealable transparent films for textile bags in range of 25-42 microns. Films are generally offered with one side treated surface for enabling surface printing. Just like the adhesive tape films, these films offer excellent flatness, gloss and clarity. They also offer good mechanical properties for pouching applications.

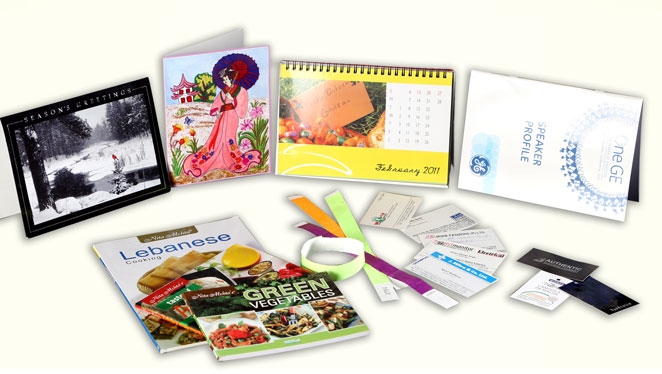

Synthetic Paper

Synthetic paper is a replacement of paper in applications where durability and longevity is desired. It is a co-extruded, white opaque, polypropylene based film which resembles paper in appearance. It is non-tearable, has moisture & chemical resistance and excellent lay flatness. The versatility of synthetic paper is reflected in the vast number of applications where it can be used. This includes areas such as commercial printing, tags & labels, retail & packaging, identification & credentials and outdoors.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.