CLEAN AIR SYSTEMS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CLEAN AIR SYSTEMS

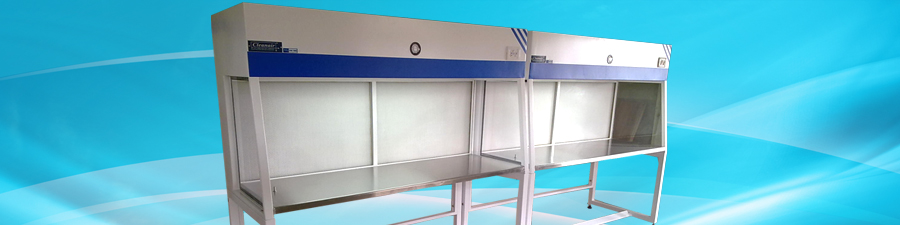

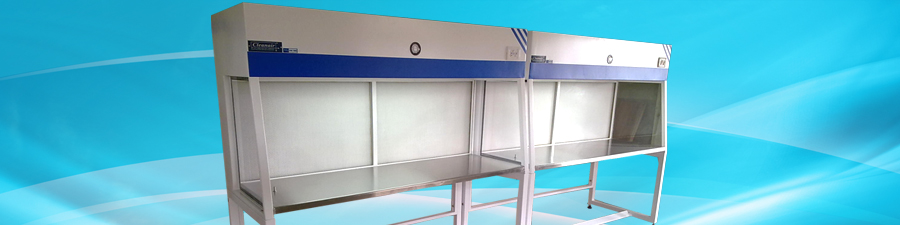

Laminar Airflows

Cleanair™ Laminar Airflow cabinets are designed and best suited for creation of a bacterial dust free air space. Laminar Airflow Cabinets are used while working in following conditions

While working with low-risk substances and materials,

when protection of working material from environment is required or

while working with items that require a sterile working zone.

Laminar Airflow Cabinets are used as equipment of local workplaces in medical, pharmaceutical and other institutes with high requirements for air cleanliness in the working zone. Cleanair specializes in designing and creating following types of Laminar Airflows.

Horizontal Laminar Airflow

Vertical Laminar Airflow

Ceiling Laminar Airflow

We also design Horizontal Laminar Airflow chambers that are witnessing great demand from various hospitals and electronic industry. The raw materials and the components used are of high quality and are rigorously tested to meet stringent quality checks. Ceiling suspended laminar air flow (CLAF) are used for OT applications, pharmacy filling & packing line etc. CLAF provides ultra clean sterile HEPA filtered CLASS 100 air in a isolated area where the highly sensitive process activities are carried-out. Cleanair CLAF available in complete stainless steel construction or GI construction with PU coated finish. Equipped with MINIPLEAT HEPA with dynamically balanced ultra-low noise blowers for optimum airflow. Differential pressure monitoring is done through MAGNEHELIC gauges. Various sizes can be manufactured and supplied to suit the specific site conditions.

Bio Hazard Safety Cabinets

Cleanair™ Biological Safety Cabinets, enclosed containers and other engineering controls are designed to remove hazardous biological materials. The biological safety cabinet is the principal device used to provide containment of infectious splashes or aerosols generated by many microbiological procedures. The equipment is widely applicable and is used in biomedicine, microbiology and gene recombination.

Air Shower Entry Systems

“Cleanair” made Air Showers employ concentrated airflows to lift off contamination such as lint, dirt, dust etc., while an individual simply moves in or walks through a specially constructed chamber. The high velocity air from jet nozzles ensures efficient scrubbing action necessary to remove particulate matter. Contaminated air then flows through sidewalls of the air shower and flows through pre filters and final HEPA filters.

Cleanair™ Air showers are self-contained air chambers installed at the entrance of clean rooms in order to keep the clean room sanitized by minimizing the amount of particulate contamination entering the clean room. Equipment and materials are sanitized by passing through the air shower pass box while particulate contamination is removed by washing with high velocity HEPA-filtered air jets. Contaminated air is then taken in through the base of the unit, filtered, and re-circulated into the chamber. To facilitate the proper removal of particulate contamination, Cleanair Air Showers are built-to-order with standard shower duration of at least 15 seconds.

Clean Room Pass Boxes

"Cleanair”™ Pass Through Box ( also known as Clean Pass Box) is designed to minimize traffic and contamination entry into the clean room. It effectively enables parts, tools and other work items to be passed to and from the room. The unit acts as an air lock device preventing ambient air from entering, or clean air from exiting, the clean room. Dynamic pass boxes are provided with vertical laminar airflow.

Standard features

Mechanical interlocking for the doors

Swing type doors with view panels

Door open indicator

Optional UV lamp

Fluorescent tube light etc.

Availability

Available in Static & Dynamic versions

Available in Different sizes to suit customer requirement

Available in complete SS or MS with PU painted construction

Powder Containment Booth

Cleanair™ make Powder containment booths are used to control the hazardous emissions of powders, dust or vapors during powder dispensing, product sampling, or bag dispensing, etc., without risk to the operator or environment. The downdraught prevents airborne dusts caused by weighing and dispensing operations rising into the operator's breathing zone. The air forced downwards is extracted at low level into the booth's filtration system where dust particles are contained at each level of filtration prior to being re-circulated back into the booths'' air stream.

Powder Containment Booths

Cleanair™ make Powder Dispensing/ Sampling Booths are designed to give mixed air flow stream for product, operator and environmental protection and used to control the hazardous emissions of dust powder during powder dispensing / sampling process. 0.3 micron downward air stream deflects air-borne dust away from the operator breathing zone which is caused in handling operation.

Dust particle available is being filtered at three levels of filtration prior to being circulated back to the booths air stream. For filling, refilling, weighing & sampling of Raw material & Components

Sterile Garment Cabinets

Our Sterile Garment Cabinets are manufactured in such manner so that these can have the highest degree of safety for both the users and for the products high efficient HEPA filters are found in these cabinets. All these cabinets are carefully constructed and tested as per the requirements of the clients.Sterile Cabinets

Cleanair™ make Garment Storage Cabinets provide the premium solution to meet your garment storage needs while making a positive contribution to maintaining the cleanliness of your controlled cleanroom environment. Cleanroom garments can accumulate particulate contamination during storage and between laundry washes, which in turn may lead to lower product yields and increased product quality issues. These cabinets are equipped with a blower and a HEPA filter in a fully contained enclosure constructed of powder-coated steel sheets, which will not shed particles or contaminate the environment of your cleanroom. They provide a solution for storing your cleanroom garments in a visible and organized manner, while at the same time removing particulate contamination from your garments as they are stored and removed.

Softwall Clean Rooms

Cleanair™ softwall cleanroom utilizes the most economical approach and design for your cleanroom needs. This design is commonly used in the microelectronics and medical mold injection industry as well as many others. Cleanair™ Tent's softwall design allows it to be used as either a totally freestanding room or it can be used in combination with your existing walls and ceiling. Each room comes completely factory prefabricated for minimal on-site erection time and is totally self-contained with all components factory-finished.

Modular Clean Rooms

Cleanair Pre-Fabricated modular cleanrooms are designed to provide a dust free and clean environment in a specific and isolated area for conducting any R&D work or assembling or any specific process activity which demands such cleanroom conditions. These custom built modular cleanrooms are designed in class 100, class 1000, class 10000 cleanliness level as per ISO 16441 Sepcifications.

Various sizes with horizontal or vertical airflow curtains can be designed to suit any specific customer requirement.

Positive Pressure Modules

As part of its state of the art offerings, Clean Air Systems also offers, top-of-the-line Positive Pressure Modules. These are highly specialized equipments and are carefully designed to provide a clean area within a small enclosure or a cell. The Positive Pressure modules are designed and work on the principle similar to that of the Laminar Airflow. Fixed at the rear end of the unit is the pre-filter. While a bowler assembly is used for the purpose of air suction, the air is passed through the HEPA filter where the filtrations of highest level take place. Positive Pressure Modules designed by Clean Air Systems are unique and offer high value for money. Every Positive Pressure Module is carefully designed and inspected to perfection.

Clean Air Fan Filter Unit

Cleanair™ Fan Filter Units are self-contained, motorized Supply Air Modules equipped with either HEPA or ULPA filters. Our FFU's can be used in either horizontal or vertical flow positions, wherever clean air is needed. The clean air fan filter module includes a fan shroud, a fan/motor mount, a centrifugal fan, a fan motor, and a HEPA filter, the fan shroud having an air inlet and two inclined ends, the fan/motor mounted below the air inlet on the fan/motor mount, the centrifugal fan blowing air radially towards the fan shroud, the HEPA filter constituting the air outlet.

Fan Filter unit is generally used to supply purified air to the clean room for manufacturing semiconductor, liquid crystal, etc. The installation space is the system ceiling grid. For a large clean room, the number of required FFU is from several hundred to several thousands.

Laboratory Fume Exhaust Hood

Laboratory fume hoods are moderately covered workspaces that are exhausted to the outer side. The prime objective of laboratory fume hoods is to keep poisonous or irksome vapors out of the general laboratory working area. Another purpose is to serve as a protective layer between the worker and the equipment being used when there is the possibility of an explosive reaction, or to protect the specimen. Laboratory hoods are comprised of the hood itself and a sash, which is the front panel of the fume hood that can be opened and closed to maximize access and minimize airflow.

The efficiency of a laboratory hood is measured by its hood face velocity and required air flow. Hood face velocity is a measurement of air flow speed across the imaginary plane running between the bottom of the sash to the work surface. Generally measured in feet per minute (fpm), the greater the hood face velocity, the more quickly toxins and other vapors can be flushed from the system. Required airflow is related to hood face velocity in that it is a measurement of the amount of air flow required to achieve a laminar flow velocity of 100 feet per minute.

The Fume Cupboard is closed on three sides and front side provided with 5 mm thick polycarbonate sliding door. The fume chamber is provided with a centrifugal blower mounted on top of the Hood, coupled directly with a suitable motor for sucking the fumes from the hood and forcing it to go out to the atmosphere through the duct. The blower and casing will be made of mild steel with polyurethane paint coated / FRP finish.

Cleanair™ Laboratory Fume Exhaust hoods are readily available in metal construction with inner FRP lining or in complete FRP constructions. Heavy-duty and dynamically balanced blower assembly provided in the unit removes smoke / fumes / odor from any chemical process conducted in the hood. Work surface of these Fume Hoods is equipped with acid proof ceramic lining or with finely polished granite. The front sash is connected to suitably balanced counter weigh for convenient vertical sliding.

The Fume Hoods are also provided with suitable lighting inside the work chamber. They are available with or without storage cupboard under the workbench and are also available in ductless type also, with activated carbon filter to remove heavy odors. Standard features power points to work with any small electrical equipments, inlet nozzles for gas / air / vacuum etc. Optional features include water sink with inlet and outlet Flameproof electrical accessories such as FLP lighting, FLP motor & starter, FLP plug points Available in various sizes to suit user requirement.

Island Table

Island Tables designed by Clean Air systems are top of the line and are provided with locking arrangements. The shutters provided in these benches are fitted with hinges and the shutter modules have removable shelves. Apart from this, the modules for sink tables are specially designed for the fitment of sinks.

Instrumentation Table

We are instrumental in offering our clients with a wide range of Instrument Table that is widely demanded in laboratories and hospitals for placing different surgical instruments. Competitively priced, our range of Instrument Table can be delivered in bulk quantities within a short time span.

Wall Cupboard

Clean Air has also mastered manufacturing Wall Units for laboratories and medical facilities, which is generally appreciated for its ample space. Designed based on latest technology, these wall units are widely used in laboratory and medical facilities. Not only are these units are available in different sizes, they also accommodate product in an organized manner, thus making it easier for lab attendants and professionals to manage well.

Some of the main features are:

Spacious

Termite resistance

Durable

Sink Unit

Clean Air offers a wide range of Sink Unit that is used in laboratories and medical facilities. These are extensively used for manually and hygienically washing different laboratory accessories. We also offer these in customized specifications.

Salient features:

Sink Units are of low maintenance

Highly Durable

Conveniently Designed to meet the customer’s expectations

Air Curtain

Cleanair™ Air curtains are the best suited elements to control the indoor climate in all the places where the doors cannot always be closed. The preliminary purpose of these Air Curtains is to disallow the influx of outside air through an opening. These are used to not only prevent cold air from pushing its way in, but also prevent warm air from going outside the door. They also keep the air fresh by preventing pollution, dust, insects, reducing the heating energy loses and eliminating cold draughts.

Air Curtains are extremely beneficial to the food industry, distribution and retail trade within the food sector. By installing an air curtain, the door to a room can be left open while keeping the temperature at a constant low level. In the processing, storage and transport of the articles of food this works efficiently while the door does not have to be opened and closed continuously for passing trucks. Let us take an example of Supermarket where sales promoting is efficient due to air curtains for chill room where fresh food is kept.

The Air Curtains find their use in following areas:

Air Conditioned Areas

Industrial Climate Control

Humidity and Dust Control

Commercial Areas

Cold Storage etc.

Clean Room Validations

We undertake complete validation documentation of clean room & all kinds of cleanroom equipments which is as follows:

Particle Counting

DOP Test. PAO Test

Filter Leak Test

Airflow pattern

Air change calculation by fume hood

Biosafety cabinet certification

Laminar airflow certification

Recovery test

Containment Leak test

Air balancing/ Pressure Balancing

Temperature & humidity Mapping

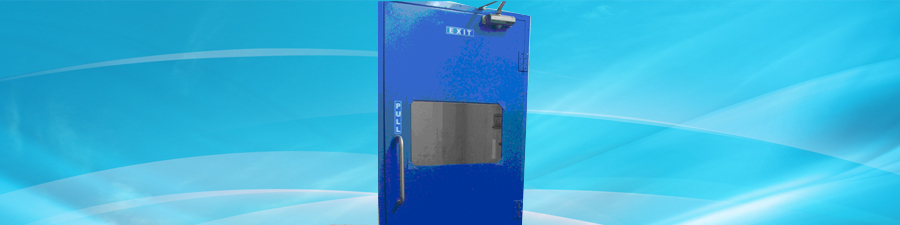

Metal Door

best quality and aesthetically designed metal doors that are suitable for Pharmaceutical industries, Cleanrooms, Process industries, Hospitals and other institutions and medical facilities. Our reputation in the market segment has been long lasting and we have designed and delivered Metal doors to some of the most prestigious customers. These doors are made of galvanized iron sheets and are completely finished with epoxy powder coat. The doors are made of double layer and polyurethane foam sandwiched in between the layers for thermal insulation. Each and every Metal door is comprised of a heavy-duty metal outer frame and swing type doors connected to the frame with the help of stainless steel hinges.

Each door is provided with “D” type stainless steel handles on both sides, double layered clear glass view panels of 300mm x 300mm size, good quality lock & keys stainless steel hinges and automatic door closures of good ISI brand.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.