CLEAN AIR SYSTEMS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CLEAN AIR SYSTEMS

Powder Containment Booth

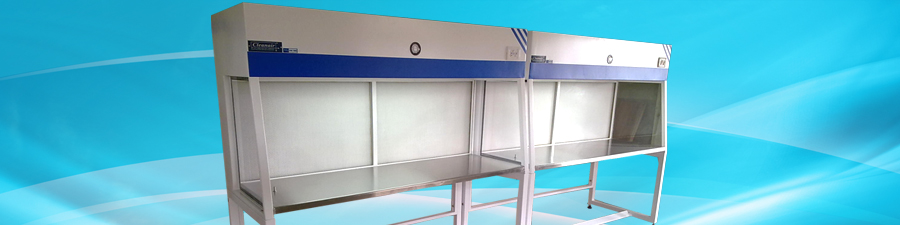

Cleanair™ make Powder containment booths are used to control the hazardous emissions of powders, dust or vapors during powder dispensing, product sampling, or bag dispensing, etc., without risk to the operator or environment. The downdraught prevents airborne dusts caused by weighing and dispensing operations rising into the operator's breathing zone. The air forced downwards is extracted at low level into the booth's filtration system where dust particles are contained at each level of filtration prior to being re-circulated back into the booths'' air stream.

Powder Containment Booths

Cleanair™ make Powder Dispensing/ Sampling Booths are designed to give mixed air flow stream for product, operator and environmental protection and used to control the hazardous emissions of dust powder during powder dispensing / sampling process. 0.3 micron downward air stream deflects air-borne dust away from the operator breathing zone which is caused in handling operation.

Dust particle available is being filtered at three levels of filtration prior to being circulated back to the booths air stream. For filling, refilling, weighing & sampling of Raw material & Components

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.